Today’s electrical systems use microprocessors, control systems and networks, providing power to homes and large factories. The more we rely on constant power, the more we are at risk from power surges. When surges happen due to lightning strikes or switching in the grid, they can seriously damage sensitive equipment. This necessitates robust surge protection.

The effects of a power surge are not limited to broken equipment or money lost. They may result in important failures, including losing data from servers or having hospital systems fail. Therefore, it is important to handle and reduce high-energy electrical surges to ensure electrical systems are reliable and safe. A comprehensive surge protection system is no longer a luxury but a necessity.

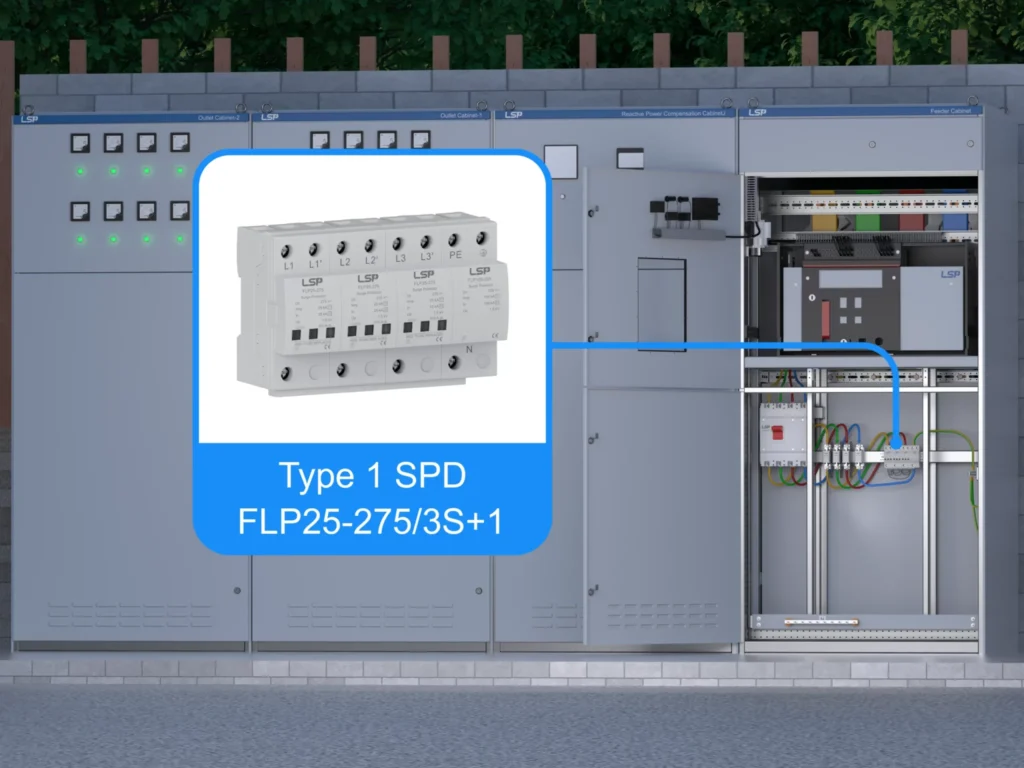

Type 1 SPDs are built to manage the high-energy transients that occur when lightning strikes or when there is a major change in the power supply. Without this protective device, energy could reach the main electrical panel and damage many parts of the installation. Installing a Type 1 SPD is important not only to meet new standards but also to improve the system’s ability to withstand problems. This crucial surge protective device is essential for maintaining the safety and ongoing operation of electrical infrastructure today.

Understanding Type 1 SPDs: Your First Line of Defense

To understand the importance of Type 1 SPDs, it’s essential to know what they do and how they are built. Unlike Type 2 and Type 3 SPDs, Type 1 devices are designed to withstand the most powerful surges—particularly those from direct lightning strikes and other major external events. They serve as the first and most robust line of defense in a surge protection strategy.

Type 1 SPDs respond to sudden increases in voltage. Their internal components—such as spark gaps or metal oxide varistors (MOVs)—transition from non-conductive to conductive states when a surge occurs, providing a low-impedance path to ground. This protects downstream equipment by diverting dangerous overvoltages. Once the surge passes, the SPD returns to its high-resistance state, allowing normal electrical flow to resume.

A key characteristic of Type 1 SPDs is their ability to handle high-energy events, measured using the 10/350 µs waveform, which simulates the energy and duration of a lightning strike. Their impulse current rating, typically expressed in kiloamperes (kA), reflects their capacity to manage such extreme conditions. Installed at the service entrance before the main overcurrent protective device, these SPDs help prevent powerful surges from entering the electrical system. If this critical protection is missing or fails, downstream components may be vulnerable to surge damage and system instability.

Installation Planning: Where and When to Use a Type 1 SPD

The effectiveness of a Type 1 Surge Protective Device (SPD) relies not only on its built-in protective features but also heavily on where it is installed. Strategic placement is crucial for optimal performance and the overall safety of an electrical system. Knowing when and where to install these devices is key to using them effectively. The primary location for a Type 1 SPD is at the service entrance, on the side of the main overcurrent protective device (like the main circuit breaker or fuse). This positioning allows the SPD to be the first line of defense against sudden overvoltages from the utility grid or lightning, as it is directly connected to the power lines and can safely redirect large surges to the ground before they enter the facility’s electrical system.

In addition to the service entrance, Type 1 SPDs are also critical in buildings equipped with a lightning protection system (LPS). While lightning rods help channel strikes to a safe path, some of the lightning current can still couple into the electrical wiring. In such cases, a Type 1 SPD becomes essential, as it provides a secondary level of protection by diverting any residual surge energy to the ground, thereby protecting internal electrical equipment from potential damage.

In addition, there are many applications where Type 1 SPDs are absolutely necessary.

| Application | Reason / Description |

| Commercial and Industrial Facilities | These locations contain sensitive equipment, expensive machinery, control systems, and data networks. Any downtime can lead to significant financial losses. Surges can easily disrupt operations in factories, manufacturing plants, and processing facilities. |

| Critical Infrastructure | Hospitals, data centers, telecommunications hubs, and emergency services buildings require uninterrupted power at all times. Type 1 SPDs help protect the public and essential services from external electrical disturbances. |

| Buildings with Overhead Power Lines | Buildings that receive power through overhead lines are more vulnerable to lightning strikes and switching transients than those with underground systems. Due to the higher risk, Type 1 SPDs are necessary to ensure strong surge protection. |

| High-Value Residential Properties | While typically associated with industrial settings, large modern homes with smart features, home offices, and sensitive electronics can greatly benefit from Type 1 surge protection at the service entrance, especially in areas prone to electrical storms. |

The best time to put in a Type 1 SPD is usually during new construction or when major electrical work is being done. If these protective device are added during the first design phase, they can be placed optimally, have shorter connections and fit easily into the electrical system. At the same time, upgrading existing installations is now a common approach, thanks to new electrical rules and a better understanding of the importance of surge protection. The money spent on proactive installation is much less than what you could lose from broken equipment, lost information and a halt in operations due to a surge.

Step-by-Step Installation Guide

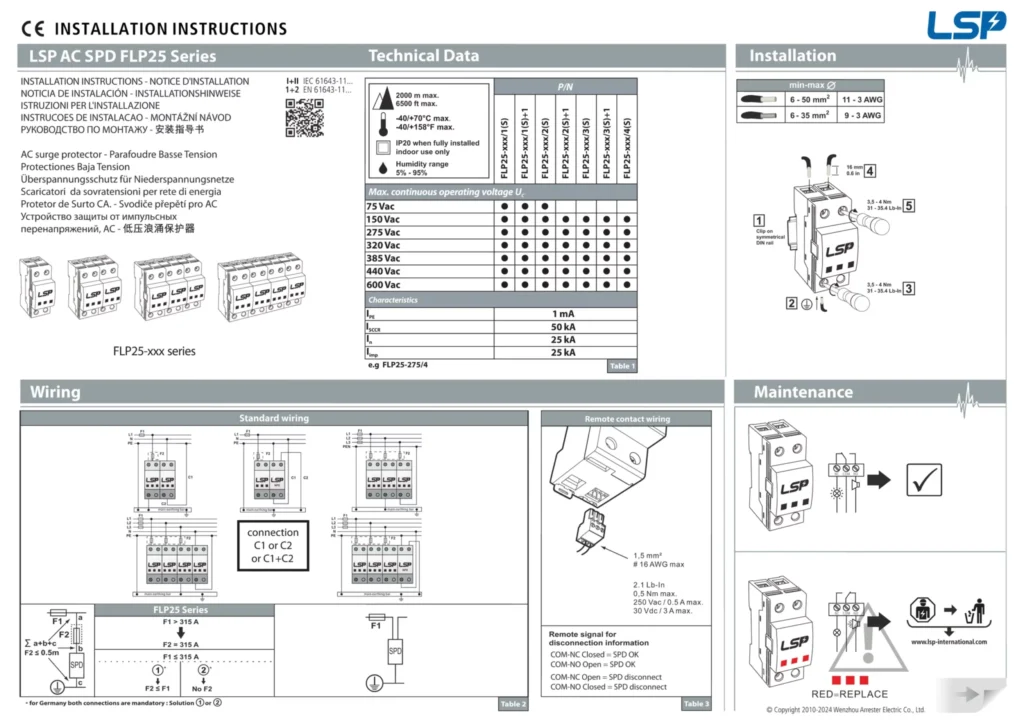

Installing a Type 1 Surge Protective Device (SPD) requiresprecision, strict safety protocols, and solid electrical knowledge. While this guide provides a general overview, only qualified electricians should perform the installation, following the manufacturer’s instructions and all relevant codes.

Safety First

- De-energize: Switch the main service disconnect to OFF. Confirm zero voltage on all phases, neutral, and ground with a multimeter.

- Lockout/Tagout: Apply LOTO procedures to prevent accidental energization.

- System Check: Confirm system type (single-phase, three-phase, delta, wye) and SPD compatibility.

Choosing the Installation Location

Install the Type 1 SPD as close as possible to the service entrance, typically in or near the main panel. Key points:

- Minimize Lead Length: Keep conductors as short and straight as possible—ideally under 0.5 meters (20 inches)—to reduce inductance and improve protection.

- Maintain Clearances: Ensure proper working space per electrical code.

Mounting the SPD

- Securely mount the SPD to a stable surface, such as the panel enclosure or adjacent wall, using suitable hardware. Ensure it’s accessible for inspection.

- For outdoor installations, ensure proper IP or NEMA rating.

Wiring Connections

Type 1 SPDs are wired in parallel, upstream of the main breaker. Follow these steps:

- Ground (PE): Connect the SPD’s ground (green or green/yellow) directly to the main grounding electrode or busbar, using a short, straight, and robust conductor.

- Neutral (N): If required, connect the neutral (white or blue) to the main neutral busbar.

- Phases (L1, L2, L3): Connect phase wires (black, red, blue) to the incoming service conductors, before the main breaker.

- Twist Wires: Gently twist conductors together to reduce inductance.

- Tighten Connections: Follow torque specs. Loose connections risk overheating.

Overcurrent Protection

Some SPDs include internal protection; others may require external OCPDs. Always follow the manufacturer’s instructions.

Final Checks

- Inspect: Confirm tight connections, proper wiring, and secure mounting.

- Test Grounding: Verify low-impedance grounding (<0.1Ω) if applicable.

- Re-energize: Restore power and check SPD status indicators (green/blue = OK, red/off = fault).

Conclusion

Installing a Type 1 SPD is not just wiring—it’s building a critical layer of protection for your system. Attention to detail ensures your SPD performs when needed most.

* Type 1 SPD Installation PDF

Navigating Standards and Technical Specifications

Surge Protective Devices (SPDs) are designed and tested according to strict standards. All our products are made and tested to meet the requirements of IEC 61643-11, a worldwide standard for low-voltage SPDs.

IEC 61643-11 sorts SPDs by their purpose and the tests used to evaluate them. To test Type 1 SPDs, a 10/350 µs impulse current waveform is used to simulate partial lightning currents. Important factors to consider are:

| Term | Definition |

|---|---|

| Impulse Current (Iimp) | The peak surge current the SPD can withstand in a 10/350 µs waveform test. |

| Voltage Protection Level (Up) | The maximum voltage the SPD allows through during a surge; lower values mean better protection. |

| Uc | The highest continuous voltage the SPD can tolerate without conducting current. |

| Isccr | The maximum short-circuit current that both the SPD and upstream protection can safely withstand. |

In North America, UL 1449 is the main standard for SPDs. Although the terms and tests are different (using the 8/20 µs waveform), the main goal of both standards is to protect against surges. UL Type 1 SPDs are usually put at the service entrance and are defined by the following parameters:

| Term | Definition |

|---|---|

| Maximum Current | The highest surge current the SPD can handle during 15 surges in an 8/20 µs waveform test. |

| Voltage Protection Rating (VPR) | The clamping voltage level measured during an In (nominal discharge current) test. |

| Maximum Continuous Operating Voltage (MCOV) | The maximum continuous voltage the SPD can withstand; equivalent to IEC’s Uc value. |

| SCCR (Short-Circuit Current Rating) | The maximum fault current the SPD can safely withstand without damage or risk of failure. |

In addition to SPD specifications, the idea of coordination is crucial. It means that each SPD type (Type 1, Type 2, Type 3) is installed in the right order to provide complete surge protection. Type 1 SPDs are responsible for the first big surge and Type 2 and Type 3 devices take care of any remaining surges or transients that occur inside the system. Choosing the right Type 1 SPD requires:

- System Voltage and Configuration: Ensuring the SPD is rated for the same voltage as the electrical system.

- Risk of Direct Strike: Determining the chances of a lightning strike or a major surge in the electrical system.

- Fault Current Levels: Checking that the SPD’s SCCR is strong enough for the fault currents at the installation point.

- Protection Level (Up or VPR): Pick an SPD that has the lowest voltage protection level that can manage the expected surge currents.

Following these standards is important for both compliance and to ensure your electrical installations are reliable, safe and last a long time. It provides the structure needed to create an electrical system that can handle unexpected problems that would knock out weaker systems.

Maintenance & Longevity: Protecting Your Investment

While a Type 1 SPD helps protect your electrical system, it needs to be checked and maintained regularly to keep working well and last for a long time. Although Type 1 SPDs are built to last, the process of absorbing high-energy transients can cause their internal parts to wear out over time or after major events.

Important Maintenance Practices:

- Check the LEDs and flags to confirm that the SPD is working. If the SPD shows a red light or a tripped flag, it means the SPD has taken in a large surge or is no longer working.

- Check for any damage, signs of overheating, loose wires or corrosion. Deal with any problems as soon as you notice them.

- The SPD environment should be kept clean, dry and without too much dust or moisture.

Testing (Periodic):

- Testing: Performing surge capacity tests on-site is not simple, but electricians can check insulation resistance and connections.

- Some SPDs include self-diagnostics or remote monitoring which makes it easier to maintain them.

Documentation:

Record the date each device was installed, its model number and any changes in its status for simple tracking and future use.

What Affects How Long We Live:

- The more often or strongly surges occur, the quicker the SPD parts will wear out.

- For the system to work well and last long, it must be wired correctly, have secure connections and be grounded.

- Temperature, humidity and corrosion can cause items to age more quickly.

Replacement Strategy:

- Replace the SPD when the indicator on the device indicates it is time to do so.

- Replace the SPD after a major lightning event or when it is close to the end of its life or has taken in several large surges.

Conclusion

You must keep an eye on your Type 1 SPD to make sure it is still protecting your electrical system. If you act quickly, your protection will be ready for power surges and unexpected events.

Why Choose LSP for Type 1 SPDs

Durable Type 1 Surge Protective Device for Long-Lasting Reliability

At LSP, we have been dedicated to the research and production of surge protection devices (SPDs) since 2010, with a strong focus on delivering reliable Type 1 SPDs to global markets. With over a decade of experience, our products are now exported to more than 10 countries, supported by two automated production lines and a 1600㎡ facility certified with ISO9001, TUV, CB, and CE. We ensure production efficiency with a standard delivery time of 10–15 days for regular models and one month for custom orders. Even in cases with no inventory, we maintain a maximum lead time of two months.

What sets our Type 1 SPDs apart is our commitment to high-performance components and rigorous testing. We use top-tier materials like LKD MOVs and Vactech GDTs, both trusted by global SPD leaders. Our metal parts undergo a 48-hour salt spray test and feature thicker terminals (8mm x 0.8mm) for enhanced durability. Our SPDs are designed with an internal disconnector that has been developed over three years, ensuring safe isolation and arc suppression during surges. With dual testing certifications (8/20 and 10/350 waveforms), low-temperature tripping technology, and added moisture protection, our Type 1 SPDs offer unmatched safety and lifespan of over five years.

We also provide customized solutions to meet specific market needs. Our in-house R&D team supports design customization, 3D modeling for marketing, and assistance with obtaining secondary certifications like TUV, CB, and CE. From pre-sales technical consultation to efficient logistics and global after-sales support, including a 5-year warranty and fast response times, we aim to deliver not just high-quality products but a complete, reliable service experience.

Conclusion: Secure Your System, Secure Your Future

Today, electrical systems are always at risk from transient overvoltages. Such sudden, unexpected surges, caused by lightning or major grid problems, may harm and disrupt sensitive equipment. If this risk is ignored, important infrastructure could be disrupted and suffer significant losses.

The Type 1 SPD is the initial and most important barrier against external electrical hazards. It is placed at the start of your electrical system to take in and redirect powerful surges before they can harm equipment, interrupt work or endanger people. It is this layer that makes the electrical system more resilient.

By investing in Type 1 SPDs, you can avoid losing money from equipment breakdowns, maintain continuous operation and make your workplace safer. Selecting a manufacturer like LSP which is recognized for its top performance and following international standards, guarantees your protection is excellent. Because technology is so important today, it is necessary to use surge protection to keep both current and future operations safe.

Frequently Asked Questions

Q1: What is the primary difference between a Type 1 and Type 2 SPD?

A1: Type 1 SPDs handle high-energy surges like direct lightning strikes and are installed at the service entrance. They’re tested with a 10/350 µs waveform. Type 2 SPDs protect against smaller, residual or internal surges and are installed in distribution panels, tested with an 8/20 µs waveform.

Q2: Can a Type 1 SPD protect against all types of surges?

A2: No. Type 1 SPDs protect against large external surges but not all internal or residual surges. For full protection, use Type 2 and Type 3 SPDs in a coordinated system.

Q3: Where should a Type 1 SPD be installed?

A3: At the building’s service entrance, either before or after the main breaker, depending on standards and product type.

Q4: How important is lead length in Type 1 SPD installation?

A4: Very important. Short, straight wires (preferably under 0.5 meters total) reduce inductance and improve SPD performance.