A Surge Protective Device (SPD) is a critical yet often underestimated component in the protection of modern electrical power systems. Though typically hidden in electrical panels, its role is paramount: to react with an immediate and effective response time to power surges, diverting excess electrical energy away from sensitive equipment. These surges may be caused by lightning strikes, utility grid activity, or the cycling of heavy machinery, all of which can inject sudden, high-energy transient voltages into the power line. The destructive potential of such an overvoltage can damage or destroy entire electronic systems. The effects range from the gradual wear of components to the instantaneous and complete failure of electronic equipment.

In such an environment, an SPD is not an optional extra but a fundamental element of electrical reliability and risk management. However, its surge protection capability is not permanent. An SPD can degrade over time or sacrifice itself after intercepting a significant surge current, rendering it ineffective and creating a potential point of failure. Periodic inspection and testing of your surge protection device is thus a core maintenance activity, essential for ensuring the best protection. This guide is dedicated to the vital practices of understanding, verifying, and maintaining these crucial protective devices to secure electrical safety and system longevity.

Protecting Your Gear: Why Checking Your SPD Matters

Protection is the primary purpose of a Surge Protective Device (SPD). It serves as an essential shield between your gear and potentially damaging electrical transients. However, if this barrier is compromised, the consequences can be devastating, extending beyond the cost of replacing damaged equipment to the integrity of your operations and overall safety. Neglecting the status of your SPDs is a significant risk, exposing valuable assets to unpredictable and potentially catastrophic events like a direct spike in AC power.

The financial costs of a failed SPD can be substantial. A single, unchecked surge can cripple high-value electronic equipment, including data center servers, medical imaging systems, or industrial programmable logic controllers (PLCs). Beyond the replacement cost, the resulting downtime can paralyze operations. A stalled manufacturing line, a crashed service platform, or a malfunctioning hospital device can trigger a cascade of losses in productivity, revenue, and—in the most severe cases—even human health.

Also of great concern is the cumulative, invisible damage from smaller, frequent surges that often originate within a facility. These lower-level transients might not cause immediate failure, but they systematically degrade electronic components. When a weakened SPD fails to clamp these voltage surges, the result is diminished equipment reliability and lifespan, manifesting as frequent, hard-to-diagnose malfunctions. A low-cost, high-impact approach to SPD inspection transforms your maintenance from reactive troubleshooting to proactive risk prevention, safeguarding both performance and peace of mind, providing far better protection than leaving it to chance.

How SPDs Work: Understanding the Core Principles

Surge Protective Devices (SPDs) are an essential component of any contemporary electrical system, as they protect sensitive equipment against voltage surges that may occur due to lightning, switching, or power grid disturbances. Being a component of residential and industrial protection systems, SPDs guarantee reliability of systems and durability of equipment. Knowledge of the basic principles of their operation not only contributes to effective maintenance but also assists in choosing the level of protection that is suitable for various applications. The table below gives a clear picture of the key operational features that characterize the way SPDs operate.

| Step | Operating Condition | SPD Behavior | Description |

| 1 | Normal Voltage Condition | High Impedance (Inactive) | The SPD, typically using an MOV, remains in a high-resistance state. It allows the normal flow of electrical current without interference. |

| 2 | Surge Occurrence (Overvoltage) | Low Impedance (Active) | When line voltage exceeds the MOV’s threshold, the impedance drops rapidly. The SPD creates a low-resistance path to divert surge current safely to the ground line. |

| 3 | Surge Absorption | Energy Dissipation | The SPD absorbs much energy surge energy (rated in joules). This protects downstream equipment by preventing the surge from passing through. |

| 4 | Post-Surge Recovery | Return to High Impedance | As soon as the voltage normalizes, the SPD returns to its high-impedance state, resuming normal operation. |

| 5 | Component Degradation Over Time | Gradual Wear or Failure | Each surge slightly degrades the MOV. Severe surges may cause it to fail, either by shorting or being disconnected by an internal fuse to maintain circuit safety. |

The knowledge of these operating procedures explains the importance of frequent inspection and prompt replacement of SPDs. Knowing the surge protection device working principle helps explain how degradation occurs over time with repeated surges. Although SPDs are effective guardians against transient surges, they lose their effectiveness with time as a result of cumulative damage.

Spotting SPD Status: The Visual Inspection Method

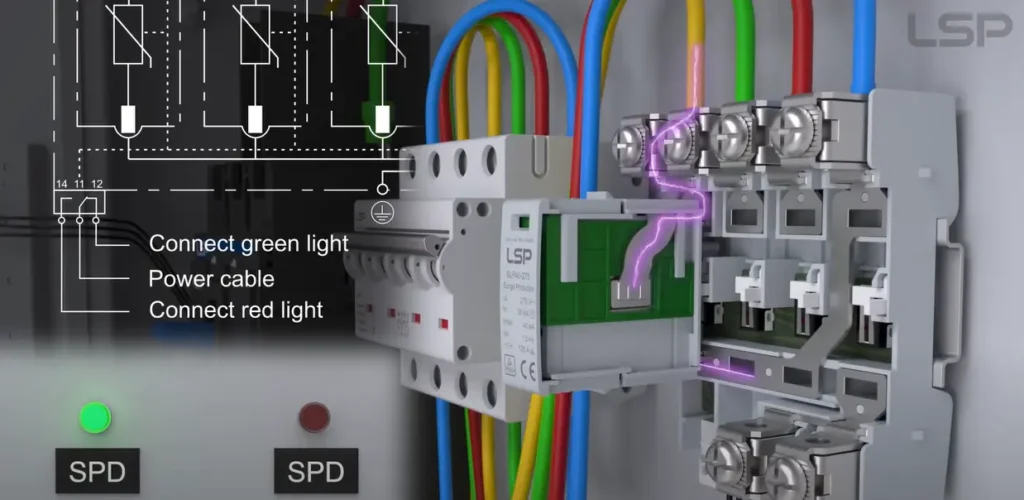

A direct visual inspection is the most fundamental and accessible method for determining the health of an SPD. Manufacturers, understanding that not all personnel interacting with electrical panels are specialized technicians, have simplified this process. Most contemporary SPDs are equipped with a status indicator.

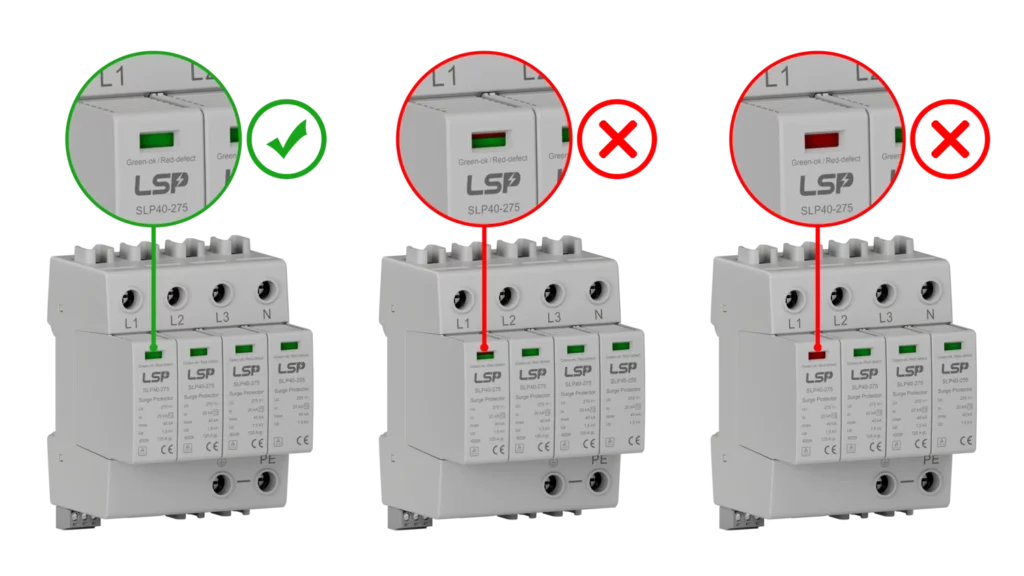

This indicator is the primary means for the SPD to communicate its state. It is usually a small LED light or a mechanical flag visible through a window. The system is designed to be intuitive:

- Green Light / Clear Flag: This universally signifies a healthy, operational condition. It indicates that the protective components within the SPD are intact and prepared to respond to a surge event. The device is online and performs its standby function.

- Red Light, No Light / Red Flag: This signals a fault condition. It means the SPD has reached its end-of-life. This typically implies its internal protective components (the MOVs, for example) have been compromised or destroyed, either from a single, massive surge or the cumulative impact of numerous smaller ones. The SPD is no longer providing surge protection, and the connected equipment is now vulnerable.

Visual checks should be integrated into regular maintenance schedules. A simple walk-through, with a quick glance at the status indicators on all installed SPDs, can be a highly effective first line of defense. If an indicator shows a fault, the SPD must be replaced immediately. Relying on an SPD with a red light means the device has already failed and can no longer provide protection. Immediate replacement is necessary to ensure continued safety.

For modular SPDs, which have replaceable cartridges, this process is even more efficient. If a single module’s indicator shows a fault, only that specific module needs to be replaced, often without needing to de-energize the entire panel or trip the main breakers. This design minimizes downtime and simplifies replacement. LSP, a trusted specialist in surge protection, provides high-quality modular SPDsolutions along with expert technical support to meet diverse protection needs.

Deeper Dives: When and How to Use Professional Tools

While visual inspection is essential, it provides a binary “go/no-go” assessment. It tells you if the SPD has failed, but it doesn’t reveal the subtle degradation that precedes failure. For critical applications where even a moment of vulnerability is unacceptable, more advanced levels of protection and testing are required. This is where professional diagnostic tools are indispensable.

These instruments move beyond visual checks to quantitatively measure the electrical characteristics of the SPD‘s components. The primary tool is a specialized SPD tester or a multifunction installation tester with this capability. These devices perform key measurements:

- Varistor Voltage (Vv) or Clamping Voltage Test: This is the most crucial test. The instrument applies a controlled, limited DC power current (typically 1mA) to the MOV and measures the voltage at which it begins to conduct—its clamping voltage. This value should be within a specific range defined by the manufacturer. A reading significantly lower than specified suggests the MOV has degraded and may be “leaky,” potentially leading to premature failure. A very high reading or an open circuit means the MOV has failed. A lower clamping voltage generally offers better protection, but it must be appropriate for the system’s normal operating voltages. The Voltage Protection Rating (VPR), a key part of the UL rating, helps define this performance.

- Insulation Resistance Test: This test checks for unintended current leakage when the SPD is in its normal, high-impedance state. A low insulation resistance reading can indicate moisture, contamination, or internal component breakdown, all of which compromise the SPD‘s safety and effectiveness.

When is this advanced testing necessary?

- Critical Facilities: Data centers, hospitals, broadcasting stations, and industrial control centers cannot tolerate any downtime. Proactive testing allows for the scheduled replacement of degrading SPDs before failure, maintaining a continuous shield of protection.

- High-Risk Environments: Locations with high lightning strikes activity or heavy industrial loads that create high voltagetransients place greater stress on SPDs. More frequent, in-depth testing is a prudent measure here.

- Commissioning and Verification: When installing a new electrical system, testing each SPD confirms it wasn’t damaged during shipping or installation and is operating to UL and IEC specifications from day one.

- Post-Event Analysis: After a known major power event, testing SPDs can determine if they have been compromised, even if their visual indicators appear normal.

Using these tools requires training and a thorough understanding of electrical safety procedures, such as those outlined in the NEC (National Electrical Code). It involves working with energized circuits and must be performed by qualified electricians who understand the equipment and the risks involved.

Common Questions & Misconceptions About SPD Testing

The subject of SPD maintenance is critical but often clouded by misconceptions. Clarifying these is essential for effective maintenance protocols.

Misconception 1: “If the green light is on, it’s 100% fine.”

While a green light is positive, it’s not a guarantee of full health. It primarily indicates the thermal disconnection mechanism has not triggered and the component has not failed catastrophically. It does not measure the subtle degradation of the clamping voltage. For a standard office, a visual check is often sufficient. For a mission-critical data center, relying solely on the green light is an unnecessary risk.

Misconception 2: “SPDs last forever.”

This is fundamentally untrue. As explained, SPDs are sacrificial. Their lifespan is directly related to the number and magnitude of the surges they encounter, measured in joules. An SPD in a quiet suburban office may last for years, while one near a heavy industrial plant may need replacement much sooner. They are a consumable component, not a permanent fixture like circuit breakers or the building wiring.

Question: “How often should I check my SPDs?”

The answer depends on the criticality of protected electrical devices and the environment.

- High-Criticality/High-Risk: Monthly visual checks and annual professional testing, conforming to standards from bodies like ANSI or NEMA.

- Medium-Criticality/Standard Commercial: Quarterly to semi-annual visual inspections, with professional testing every 2-3 years or after a significant electrical event.

- Low-Risk/Residential: Annual visual checks are generally adequate for most surge suppressors.

Question: “Can I test an SPD with a standard multimeter?”

No, a typical multimeter is not accurate to test an SPD (MOV). It is incapable of producing the high voltage or current required to induce the clamping effect of an MOV, or of testing insulation resistance at suitable test voltages. Although a multimeter may indicate a fully shorted or open MOV, it cannot measure the clamping voltage or degradation. The incorrect equipment can lead to false conclusions and even safety risks. Quantitative and accurate analysis needs specialized SPD testers.

Using these tools requires training and a thorough understanding of electrical safety procedures, such as those outlined in the NEC (National Electrical Code). It involves working with energized circuits and must be performed by qualified electricians who understand the equipment and the risks involved.

Extending SPD Lifespan: Daily Maintenance and Usage Tips

While an SPD‘s life is finite, proper installation and environmental care can maximize its service duration.

- Proper Installation is Key: The effectiveness of an SPD is highly dependent on its installation. Lead lengths for wiring should be as short and direct as possible. Long, looping wires add impedance, which increases the let-through voltage seen by protected equipment, reducing SPD‘s effectiveness. Follow the manufacturer’s installation instructions, such as those compliant with the UL 1449 3rd Edition or later standards for transient voltage suppression.

- Keep it Clean and Dry:SPDs, like all electrical components, should be kept free of dust, debris, and moisture. Ensure panel doors are closed and sealed. In dusty environments, periodic, de-energized cleaning can prevent conductive buildup.

- Mind the Environment: Ensure the ambient temperature around the SPD is within its specified operating range. Excessive heat can accelerate the aging of internal components like MOVs and diodes. Ensure proper ventilation in electrical closets.

- Ensure Proper Grounding: An SPD is only as good as its connection to ground. The grounding system is the final destination for the diverted surge current. A poor or high-resistance ground connection renders SPD ineffective, whether it’s protecting a transformer or a delicate server. Regular inspection and testing of the facility’s grounding system are crucial.

The maximization of the life of an SPD is not just a matter of installing it and forgetting it. It needs an active strategy that integrates proper installation with continuous monitoring of environmental conditions and grounding quality. For detailed guidance, check our step-by-step guide on how to install surge protection device correctly. By integrating these practices into regular facility maintenance, you can be sure that your SPD will be able to work when you need it the most.

Why Choose LSP High-Quality SPDs: A Partner You Can Trust

In the process of learning how to check a surge protection device (SPD), it is also important to select one that is reliable and one that is designed to pass any inspection. We have been focusing on SPD research and production since 2010, and we export to more than 10 countries with a production capacity of 300,000 units per year at LSP. With a 1,600㎡ modern factory, two automated production lines, and certifications such as ISO9001, TUV, CB, and CE, we guarantee that all SPDs are of the highest quality.

We understand that a long-lasting SPD begins with the best materials and rigorous procedures. This is why we employ LKD MOVs and Vactech GDTs of the same quality as that used by major world brands, as well as reinforced flame-retardant plastics and metal components resistant to corrosion. The internal disconnector, low-temperature tripping technology and dual waveform testing (8/20 & 10/350) that we have developed ourselves ensure outstanding lightning protection and safe disconnection, even in severe conditions. That is, our SPDs are designed to withstand any test you subject them to.

We assist our customers in every step, starting with selection, customization, production, delivery, after-sales, and warranty. We provide up to 5-year warranty (compared to the industry average of only 2 years), 12-hour response time, 7-day no-questions-asked returns, and worldwide technical support. Be it a performance check of an SPD or a search for a new partner,LSP is the name you can rely on.

Conclusion: Securing Your Electrical Safety Starts Here

A surge protective device (SPD) is a device that operates behind the scenes and guards your electrical system against unexpected voltage surges. It is critical to its proper operation in ensuring the reliability of the modern electrical infrastructure. When its condition is not taken care of, the chances of equipment failure, unplanned downtime, and expensive losses become very high.

Effective surge protection needs to be addressed regularly. It begins with the knowledge of how SPDs operate and the requirements they have to fulfill. This information must be accompanied by periodic visual inspection and, where required, professional testing of critical systems. The long-term protection is based on proper installation and regular maintenance.

At LSP, we think that you should never consider checking yourSPD as an afterthought, and the same thing goes with the quality of the device itself. That is why we engineer all the details, including improved moisture protection, clear window indicators, and metal components that are durable, to make inspections easier and performance more reliable. We support this with practical testing, reliable lead times and the ability to tailor solutions that really work to your requirements. When you are ready to act and secure your electrical systems with confidence, LSP is there as your trusted partner, today and tomorrow.