What is SPD and Why the AC/DC Distinction Matters

A Surge Protective Device (SPD) protects electrical and sensitive electronic equipment from damaging voltage surges. It works by redirecting excess current, usually to ground, and keeping the voltage reaching the equipment at a safe level. Surges can come from lightning strikes, utility switching, or large inductive loads. SPDs act like silent guardians, intercepting harmful surges before they cause damage.

The effectiveness of an SPD depends on matching its design to the type of current in the system—either Alternating Current (AC) or Direct Current (DC). AC is standard in power grids and most building wiring, where current changes direction periodically. DC flows in one constant direction and is used in batteries, solar power systems, inverters, telecommunications, and electric vehicle infrastructure.

Using the wrong type of SPD can be dangerous. An AC SPD used in a DC system might not just fail but could cause arcing, overheating, or fire due to incompatible design. Similarly, a DC SPD used in an AC system may not perform effectively. Because AC and DC systems behave differently during surges, selecting the correct SPD is critical for safety, reliability, and equipment protection. Misapplication compromises the SPD’s function and the system’s defense.

The Fundamental Difference: AC vs DC Waveforms

To truly grasp why AC SPDs and DC SPDs are not interchangeable, and why their functionality diverges so significantly, one must first appreciate the inherent dissimilarities between Alternating Current (AC) and Direct Current (DC) waveforms. These differences are not just academic; they dictate the core design principles of any surge protection device intended for a specific electrical system.

- – Alternating Current (AC), as its name implies, does not flow steadily in one direction. Instead, its voltage and current periodically reverse, oscillating back and forth. In most AC power systems, such as the mains grid that powers our homes and industries, this oscillation follows a sinusoidal pattern. The AC voltage rises to a peak in one direction, falls through zero volts, rises to a peak in the opposite direction, and falls through zero again, completing a cycle. This cyclical nature is typically rated by its frequency, commonly 50 Hertz (Hz) or 60 Hz, meaning the current completes 50 or 60 such cycles per second. The paramount characteristic of AC power here, from a surge protection perspective, is the zero crossing – a point in each cycle where the voltage (and current, in a resistive circuit) momentarily becomes zero. This natural, periodic interruption in energy flow is a crucial ally for an AC surge protective device.

- – Direct Current (DC), in stark contrast, is characterized by its unidirectional and generally constant flow of charge. The DC voltage from a source like a battery, a solar installation (PV panel array), or a rectified power supply system maintains a consistent polarity, and the DC power flows consistently in one direction. While the DC voltage level in DC systems can fluctuate (e.g., due to load changes or charging cycles in DC applications), the direct current itself does not inherently possess a natural zero-crossing point like AC. Once a DC current path is established, the current maintains its flow unless actively and forcefully interrupted by a switching mechanism, like a breaker, or a significant change in circuit impedance. The absence of this natural “off” switch presents a distinct challenge for any DC surge protective device tasked with interrupting a DC surge.

These fundamental differences in waveforms – the rhythmic rise and fall through zero of AC versus the steadfast, unwavering flow of DC – dictate entirely different approaches to surge protection, particularly when it comes to extinguishing an electrical arc that forms when an SPD diverts a high-energy surge or voltage transient.

Zero Crossing: The Key to Arc Quenching

When an SPD activates to divert a power surge, a conductive path is created within the protective device, often involving an electrical arc across components like GDTs or other switching elements. MOVs, while not arc-based devices, are commonly used in conjunction to clamp the voltage and absorb surge energy. This arc allows the high surge current to flow to ground (often via PE – Protective Earth), away from the protected electrical equipment. Once the transient event has passed, the SPD must rapidly return to its high-impedance (non-conducting) state. This is critical to prevent normal system power (known as “follow current”) from continuing to flow through the SPD, which could lead to equipment damage (specifically to the SPD itself) and disrupt the power system. The ability to reliably extinguish this arc and interrupt any follow current is a critical aspect of SPD functionality. Here, the presence or absence of zero crossings in the waveform plays a pivotal role.

Why AC Zero Crossing Helps Dissipate Energy

In AC systems, the natural characteristic of the waveform provides a significant advantage for arc quenching. As the AC sine wave approaches its zero-crossing point (twice per cycle), the current driving the arc diminishes. At the zero-crossing itself, the current drops to zero amperes. This periodic cessation of current flow provides an opportunity for the arc to cool and de-ionize the path between the electrodes within the surge protector. This makes it much easier for the SPD’s internal components to extinguish the arc and stop conducting, effectively resetting the protection device.

Essentially, the AC power system itself assists in “putting out the fire.” The diminishing energy as the current approaches zero helps the SPD’s quenching mechanism to overcome the arc. This “self-healing” property allows AC SPDs to be designed with components that can reliably operate over many surge events without succumbing to sustained follow currents, provided the SPD is correctly rated for the system and offers the required level of protection.

How DC SPDs Overcome the Challenge Without Zero Crossing

DC systems present a far more formidable challenge for arc quenching. Since DC voltage and current are continuous and do not inherently pass through zero, an arc established by a DC surge event in a DC circuit will be fed by a constant energy source from the DC power supply. There is no natural “lull” or momentary pause in current that aids in extinguishing the arc. Quenching a DC arc is like trying to stop a relentless, fast-flowing river with a temporary dam; the pressure is unceasing, and the current shows no inclination to stop on its own. This is a major concern for reliable surge protection in DC applications.

Consequently, DC SPDs must incorporate more robust and specialized arc-quenching mechanisms. These are critical design features that distinguish a DC surge protective device from an AC surge protective device. Such mechanisms can include:

- Larger Arc Gaps: Physically increasing the distance the arc must span makes it harder to sustain.

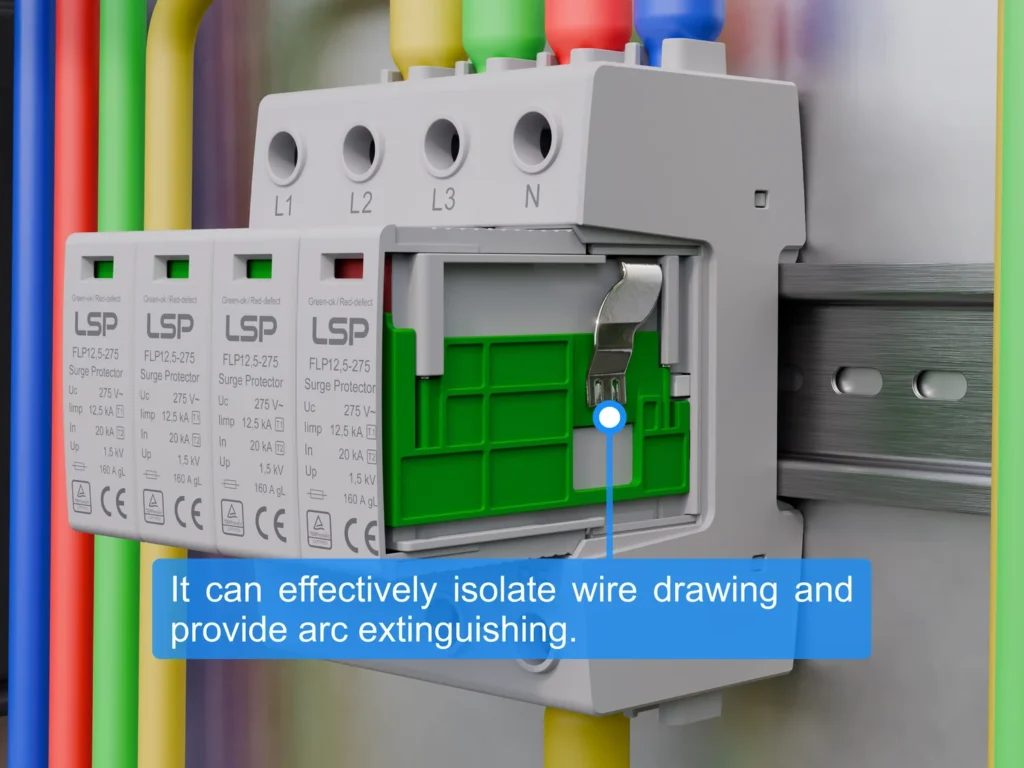

- Arc Chutes and Splitters: These are specially designed structures within the SPD that stretch, cool, and divide the arc, increasing its resistance and forcing it into cooler regions, which facilitates its extinguishment.

- Magnetic Arc Quenching: Some DC SPDs use permanent magnets or electromagnets to generate a magnetic field that deflects and lengthens the arc (Lorentz force), driving it into an arc chute or against cooling surfaces more effectively.

- Series-Connected Components: Multiple Metal Oxide Varistors (MOV) or other switching elements (like GDTs) may be connected in series. This helps to build a higher interrupting voltage capability and distribute energy dissipation, making it easier to break the direct current path.

- Specific Switching Technologies: Components like DC-rated circuit breakers, fuses, or specially designed Gas Discharge Tubes (GDTs) with enhanced DC interruption capabilities might be integrated within the SPD housing or required externally in series with the SPD.

*LSP’s carefully designed flat disconnection device forms an independent chamber upon disconnection.

The design imperative for a DC SPD is to actively and forcefully break the current path, as it cannot rely on the natural assistance of waveform zero-crossings. This often results in DC SPDs being physically larger, more complex, and sometimes more expensive than their AC counterparts for similar voltage ratings and current rating capabilities. This complexity is necessary to prevent a dangerous failure mode where leakage current could persist after a surge, leading to thermal runaway.

To address this, LSP’s DC SPDs integrate an internal tripping mechanism developed over three years, along with a disconnection device (“green board”) that provides arc isolation, window indication, and remote signaling—ensuring both safety and system visibility.

How AC and DC SPDs Handle Surges Differently

The internal construction and operational principles of AC and DC SPDs reflect these fundamental differences in arc-quenching requirements and the nature of the surge they are designed to mitigate.

| Aspect | AC SPD (Alternating Current) | DC SPD (Direct Current) |

| Primary Surge Component | Metal Oxide Varistor (MOV) | MOVs and GDTs rated specifically for DC applications |

| MOV Behavior | High resistance at normal AC voltage; resistance drops under surge to divert current | Similar principle, but must sustain and interrupt DC current without assistance from zero-crossing |

| Zero-Crossing Assistance | Yes — AC zero-crossing helps MOVs and GDTs reset by naturally interrupting current and aiding arc extinction | No — continuous current requires the SPD to forcibly break the circuit, increasing design complexity |

| GDT Role | Often used in combination with MOVs; provides low-impedance path for surge once triggered | Also used, but must be DC-rated and paired with strong arc-quenching measures |

| Arc Quenching Dependency | Supported by periodic zero current points in the AC waveform | Must be managed entirely by SPD’s internal mechanisms (e.g., magnetic blowout, arc chutes, series elements) |

| System Example | Utility power grids, AC mains | PV systems, battery storage systems, rectified industrial DC supplies |

| SPD Configuration | Typically phase-to-neutral, phase-to-ground, or phase-to-phase depending on system topology | Commonly in Y-configuration: PE–Positive, PE–Negative, and Positive–Negative |

| Follow Current Handling | Natural current interruption helps prevent sustained follow current | Requires active interruption of follow current to avoid SPD failure or thermal damage |

| Design Complexity | Relatively simpler due to waveform aid | Higher due to need for robust arc extinguishing and sustained current control |

The challenge of “follow current” is particularly acute in DC systems. If an SPD component continues to conduct significant leakage current after the initial voltage transient has passed, the DC power source will continue to feed current through it. Without a zero-crossing to aid interruption, this following current can quickly lead to thermal runaway, destroying the SPD and posing a significant fire risk. Thus, DC SPDs are rigorously designed and tested under standards like IEC 61643-31 (for PV) or UL 1449 to ensure they can break these DC follow currents effectively and safely return to a non-conducting state.

Voltage Ratings and Standards

The voltage ratings and testing standards for AC and DC SPDs also reflect their distinct operational environments and the unique stresses they encounter. Adherence to these standards, such as those from IEC, UL, or ANSI, is crucial for ensuring a protection device will perform as expected.

SPD Types Overview

Surge protective devices are categorized into different types according to their application location and surge handling capabilities:

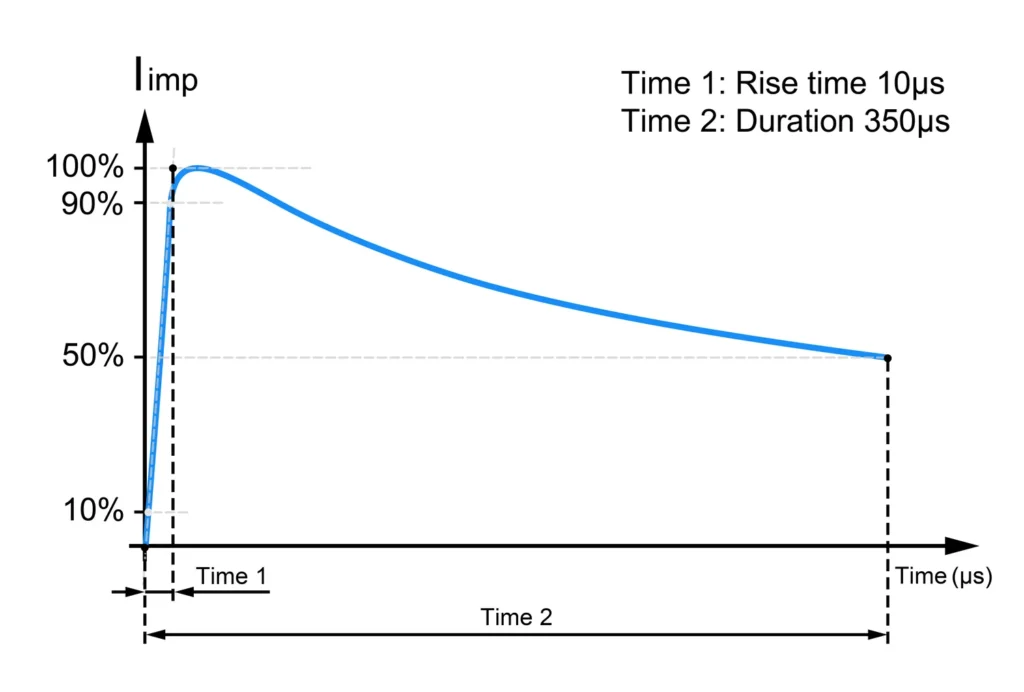

- Type 1 SPDs are designed to discharge partial lightning currents (10/350 µs waveform) and are typically installed at the origin of the electrical installation (e.g., service entrance). They are suitable for installations subject to direct lightning strikes.

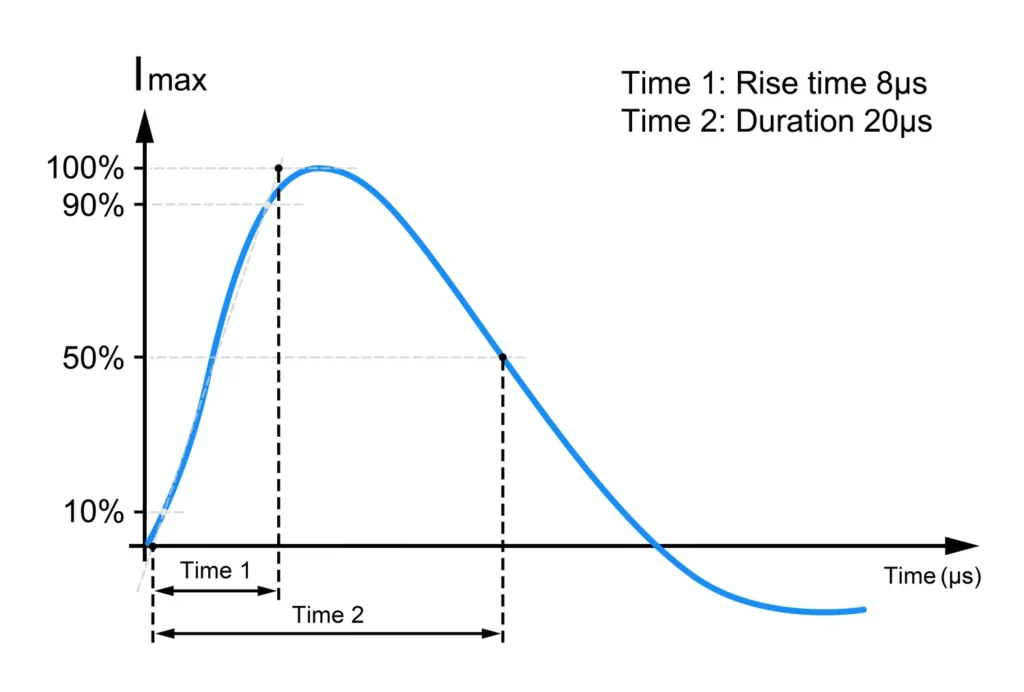

- Type 2 SPDs are designed to handle induced surges from indirect lightning strikes or switching operations. They are the most commonly used SPDs in distribution boards and are tested with an 8/20 µs current waveform.

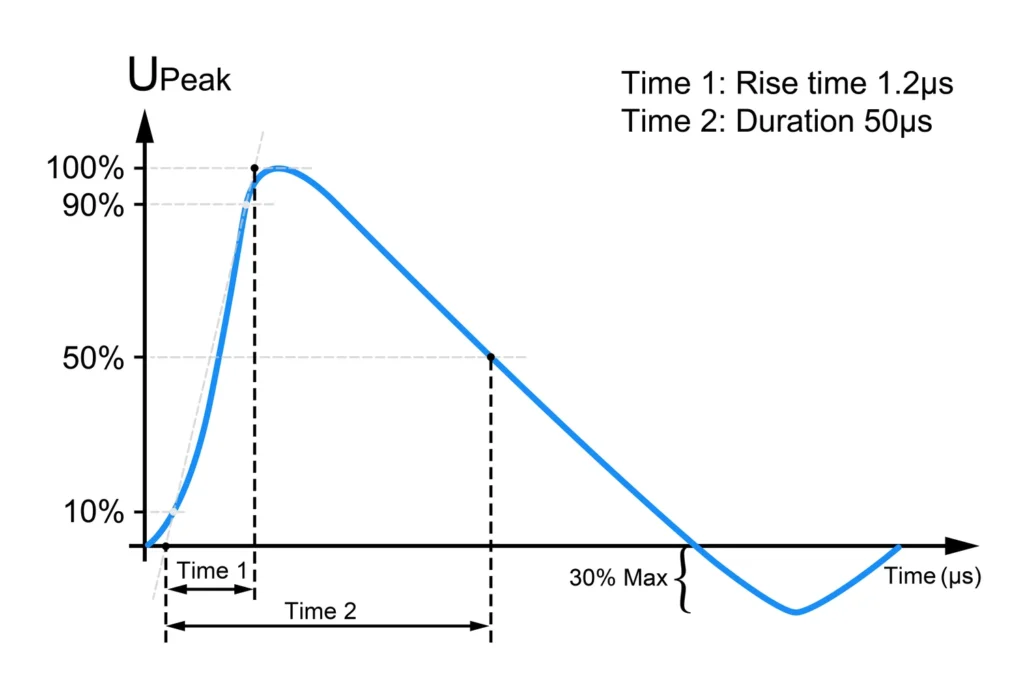

- Type 3 SPDs are intended for the protection of sensitive equipment at the load side. These are installed close to the protected equipment and are tested with a combination waveform (1.2/50 µs voltage, 8/20 µs current).

Key SPD Ratings and Definitions:

| Parameter | Description | Application Details |

| Maximum Continuous Operating Voltage (Uc) | Maximum voltage that can be continuously applied to the SPD terminals without significant conduction or degradation. | – AC SPD: Uc is based on nominal AC voltage and expected fluctuations. – DC SPD: Uc must exceed the maximum DC voltage in the system (e.g., PV string Voc or battery float voltage), considering temperature. |

| Voltage Protection Level (Up) | Residual voltage that appears across SPD terminals when it is diverting a surge at nominal discharge current (In). | – Lower Up offers better protection for sensitive equipment. – Must align with equipment’s impulse withstand voltage. – Important: Measured at SPD terminals, not at remote equipment—highlighting local protection. – Testing methods vary between AC and DC due to waveform differences. |

| Nominal Discharge Current (In) | Peak value of an 8/20 µs waveform current the SPD can withstand for multiple surges (typically 15–20) without degradation. | – Indicates SPD endurance and robustness. – Especially relevant for Type 2 SPDs. |

| Maximum Discharge Current (Imax) | Peak value of an 8/20 µs waveform current the SPD can withstand in a single surge event. | – Represents the SPD’s ability to handle high-energy, infrequent surges. – Common in Type 1 or robust Type 2 SPDs. – For Type 1 SPDs, often specified with Iimp (10/350 µs) waveform for lightning protection. |

| Short-Circuit Current Rating (SCCR or Isccr) | Maximum prospective short-circuit current the SPD can safely withstand when used with a properly rated upstream OCPD. | – Crucial for safety, especially in systems with high fault current. – In DC systems, special attention is required due to lack of current zero crossing, making arc interruption harder. – Proper coordination with fuses or breakers is essential to avoid fire or SPD failure. |

Standards and Compliance

Key international standards, such as the IEC 61643 series (e.g., IEC 61643-11 for SPDs connected to low-voltage AC power systems, IEC 61643-31 for SPDs for photovoltaic (PV) installations, and IEC 61643-41 for SPDs connected to DC low-voltage power systems) and UL 1449 in North America (which also addresses both AC and DC SPDs), provide detailed requirements and testing procedures.

These standards often have distinct parts or specific clauses addressing the unique challenges posed by AC and DC applications, reinforcing the need for application-specific surge protective devices. They also cover aspects like expected protection levels, coordination rules, and safe failure modes to ensure system reliability and safety.

Applications: Knowing When to Use AC vs DC SPDs

The choice between an AC SPD and a DC SPD is not a matter of preference but a strict requirement dictated entirely by the nature of the electrical system it is intended to protect. Using the incorrect type can result in ineffective surge protection, equipment failure, or even hazardous conditions.

Typical Use Cases for AC SPDs

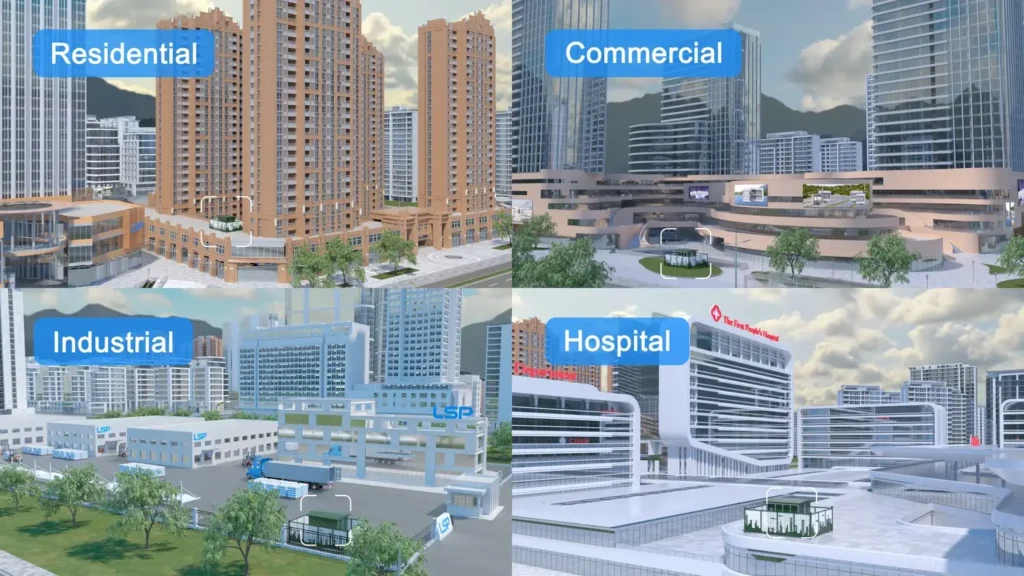

AC SPDs are essential in environments powered by standard utility grids. Common applications include:

- Residential Electrical Panels: Protecting homes and appliances from voltage surges entering through the main AC power feed.

- Commercial and Industrial Power Distribution Systems: Shielding lighting, HVAC systems, motors, and other critical loads connected to the AC power infrastructure.

- Sensitive Electronic Equipment: Safeguarding computers, data center servers, communication systems, and control panels connected to AC mains from damaging voltage transients.

- Inverter Output Side (AC Side): In solar installations or Uninterruptible Power Supplies (UPS), the output side of inverters that connects to the AC grid or AC loads requires AC surge protection.

- Machinery and Manufacturing Equipment: Protecting automated systems, robotics, and process control equipment powered by AC voltage.

Essential Applications for DC SPDs

With the rapid expansion of DC power systems, DC SPDs have become critical for ensuring system reliability and safety. Key applications include:

- Solar Photovoltaic (PV) Systems: A primary application for DC SPDs. They are indispensable on the DC side of solar arrays—between panels and inverters—in combiner boxes and at the DC input terminals of inverters. These SPDs protect against surges induced by lightning or other transients on long conductor runs. DC voltage levels in PV systems typically range from a few hundred volts up to 1500V DC or more in utility-scale installations.

- Battery Energy Storage Systems (BESS): DC SPDs protect the DC bus and battery banks, ensuring operational safety, system longevity, and equipment protection.

- Electric Vehicle (EV) Charging Stations: Especially DC fast chargers, which operate at high DC voltages and currents, require robust DC surge protection.

- Telecommunication Power Systems: Many telecom and data center infrastructures rely on -48V DC systems, which require dedicated DC SPDs to protect sensitive equipment.

- Railway Systems: DC SPDs protect onboard electronics and trackside equipment in DC traction power and signaling systems.

- Uninterruptible Power Supplies (UPS): The DC bus between the rectifier and inverter, as well as any connected battery systems, often requires DC surge protection.

- Industrial Control Systems and Automation: Many control circuits, sensors, and actuators operate on DC voltages (e.g., 24V DC) and benefit from targeted DC surge protection to ensure reliable performance.

Conclusion

Using the wrong type of SPD in these distinct electrical environments is not a minor oversight—it can severely compromise the effectiveness of surge protection and introduce safety hazards. Each SPD is engineered for the specific electrical characteristics of either AC or DC systems. Ensuring correct selection, in accordance with relevant standards such as IEC 61643, UL 1449, or EN 50539, is critical for both performance and safety.

How to Choose AC or DC SPDs? A Practical Guide

Choosing the right SPD is about matching protection to system type and risk level. Here’s a streamlined checklist:

- Identify System Type (AC or DC): Determine if the power source is AC or DC—this defines the SPD type needed.

- Check System Voltage & Configuration:

- AC: Nominal voltage (e.g., 230V, 400V), single/three-phase, grounding (TN, TT, etc.).

- DC: Voltage (e.g., 48V, 1000V), grounded or ungrounded, wiring setup.

- Select Suitable Uc (Max Continuous Operating Voltage): Uc must be ≥ system voltage. For AC, typically 110–125% of nominal; for DC, above max expected voltage.

- Assess Surge Current Capacity (In / Imax / Iimp):

- Type 1: For service entrance and lightning-prone areas—high Iimp (10/350 µs).

- Type 2: For distribution panels—rated for 8/20 µs surges.

- Type 3: For sensitive equipment—point-of-use protection.

- Verify Voltage Protection Level (Up): Up should be lower than the impulse withstand voltage of the equipment being protected.

- Check Standards Compliance: Ensure the SPD is certified (IEC, UL, etc.) and clearly rated for AC or DC use.

- Consider Installation Environment: Check SPD ratings for temperature, humidity, and enclosure (IP/NEMA).

- Confirm SCCR (Short-Circuit Current Rating): SPD’s SCCR must meet or exceed fault current at installation point and be coordinated with upstream protection.

- Look at Warranty & Support: Reliable manufacturers offer solid warranties and technical support.

The Critical Risks of Misusing SPDs

Installing the wrong type of SPD—AC in a DC system or vice versa—can lead to anything from ineffective protection to severe safety hazards and equipment failure.

Using an AC SPD in a DC System: This is the most dangerous scenario due to the absence of zero-crossings in DC power.

- No Arc Extinction: AC SPDs rely on zero-crossing to quench arcs. DC has no such feature, so arcs may persist.

- Overheating Risk: MOVs or GDTs may stay conductive, causing thermal runaway and overheating.

- Fire Hazard: Prolonged current flow can ignite the SPD, posing danger to nearby equipment and personnel.

- Ineffective Protection: AC SPDs aren’t designed for DC surge behavior, leading to inadequate protection.

- Device Damage: The SPD may fail, leaving DC equipment unprotected and exposed to surge damage.

Using a DC SPD in an AC System: While generally less immediately catastrophic than the reverse, this is still an incorrect and problematic practice:

- Subpar Performance: DC SPDs may have unsuitable clamping levels (Up) for AC waveforms, reducing protection.

- Faster Wear: AC’s voltage cycles can prematurely degrade a DC SPD or cause false operations.

- Higher Cost: DC SPDs, especially for high-voltage applications, are often more expensive than needed.

- Coordination Issues: DC SPD characteristics may not align with AC fuse or breaker coordination schemes.

In essence, the label “SPD” is not a universal passport; its validity is strictly tied to the domain – AC or DC – for which it was engineered, tested, and certified by bodies like UL or according to IEC / ANSI standards. For DC applications, understanding the role of a dc spd ensures proper surge protection and compliance.

Choosing the Right Protection: Why a Professional Manufacturer Matters

When comparing AC SPDs and DC SPDs, the differences go far beyond voltage type. AC SPDs must handle bidirectional, oscillating currents and are often installed in building distribution systems, while DC SPDs are designed for unidirectional, stable current typically found in solar PV systems, EV chargers, and industrial control panels. Because DC arcs are harder to extinguish, DC SPDs require more robust disconnection and thermal management. That’s why the technical complexity and safety requirements differ significantly—and why choosing the right manufacturer is just as important as choosing the right SPD type.

At LSP, we’ve specialized in SPD development and manufacturing since 2010, giving us over a decade of insight into both AC and DC protection. We engineer each SPD with application-specific demands in mind—our DC SPDs feature reinforced MOV encapsulation, thicker metal components, and internal arc suppression to handle high-voltage, high-current conditions without risk of fire. Our AC SPDs are optimized for fast transient suppression, stable performance after repeated surges, and reliable disconnect technology. All products are certified under IEC/EN 61643-11, and we offer dual-certified Type 1+2 SPDs tested against both 8/20 and 10/350 μs waveforms.

So, whether you’re dealing with AC mains or DC solar arrays, choosing a professional SPD manufacturer like LSP ensures you’re not just buying a component—you’re gaining a partner. We offer custom designs, support international certifications (TUV, CB, CE), and back our products with a 5-year warranty, far exceeding the industry norm. Our engineering team even provides 3D modeling and remote technical support, so your protection is always tailored, tested, and trusted.