The flow of electrical power functions as the essential life force that powers modern society in its increasingly electrified state. All people from individual device users to industrial machine operators remain connected to the power grid through a continuous electricity supply. The vital power source comes with multiple dangers. Transient overvoltage, which is also known as power surges, can represent the most dangerous threats to electrical system integrity. A surge can occur from a tiny amount of voltage increase, and voltage surges that emerge unexpectedly cause destructive effects which result in equipment damage and data loss and create safety risks.

Surge Protection Devices (SPDs) serve as the primary defense mechanism to protect sensitive electronic circuitry against electrical surges, including safety circuits such as fire detection systems and emergency lighting. These simple electrical components operate silently from electrical panels to protect valuable equipment by redirecting harmful voltage spikes. A surge protector functions effectively only when professionals select it properly and determine its correct size. The failure to properly consider this essential factor becomes equivalent to using a shield that cannot stop an approaching strike.

Understanding Surge Protection Devices (SPDs) and Why Sizing Matters

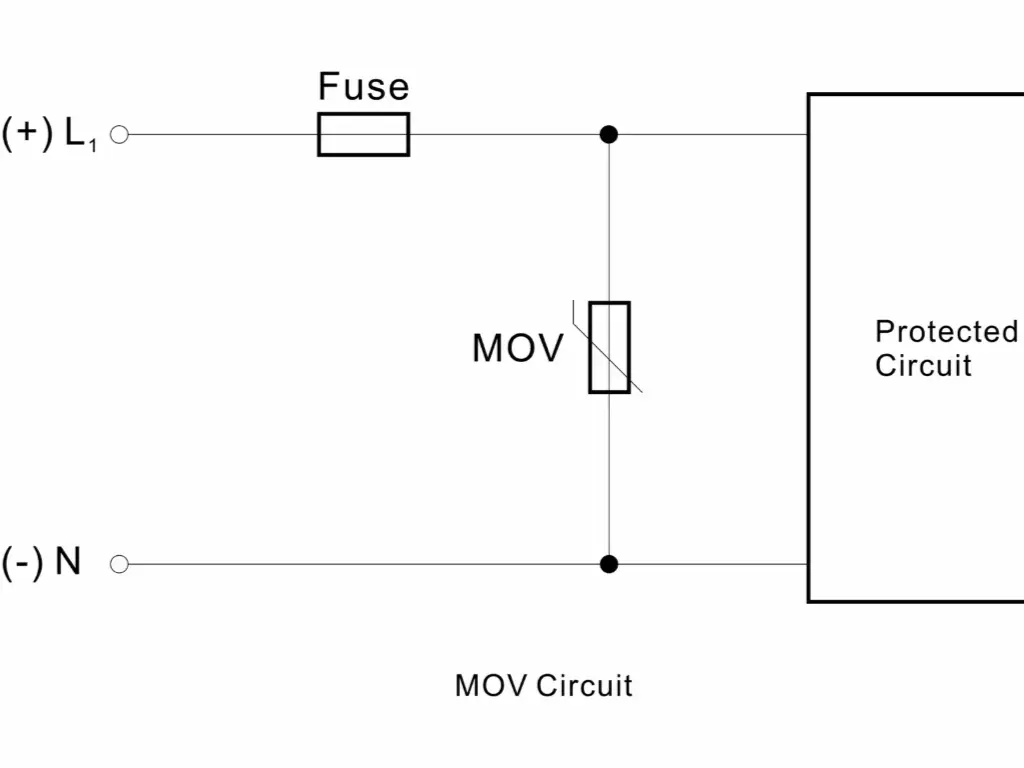

SPDs serve as protective elements that can assume the role of an additional electrode for surge current to the ground during transient events. In the most basic sense, the surge event is accompanied by seemingly uncontrollable rapid increases in voltage. The SPD recognizes this extraordinary condition, which under different conditions transitions into action to produce a temporary short that channels excess energy away from connected equipment. After the excess energy is dissipated and the surge ends, the SPD reverts back to its original state so it can protect against future potential threats.

In order to use the SPDs appropriately, their dimensioning stands as an essential factor for system protection. A poorly designed surge that exceeds the overwhelming capacity of an undersized SPD can make it ineffective while also damaging the SPD. A preposterously large SPD is even more disastrous, causing additional wasteful spending without delivering the anticipated safety by elevating response times to minimal damaging surges. This creates the challenge of custom tailoring of the power system of the SPD to exact as well as minuscule values if one wants to achieve the optimal protection level of the network. Achieving ideal correlation without overly complex coordination of the asset protection and the operational life is much simplified doing these adjustments, which lowers expensive maintenance.

The delicate electronic devices, are represented by a medical imaging machine in a hospital. The , are at risk of experiencing costly downtime due to unexpected changechanges in power flow, which can damage sensitive parts, which can and lead to mini blackouts andthat compromise patient safety. Production lines will be stopped due to surge failures in industrial control systems, which results resulting in significant operational losses in industrial plants. A correctly sized SPD serves as a protective barrier which absorbs surge energy from an electric strike to shield vital devices.

Step-by-Step Guide: Mastering the Art of SPD Sizing

The initial phase of forming effective SPD systems starts with a comprehensive understanding of the expected threat of surges. Evaluating risks always begins from a detailed analysis of several very important elements.

Step 1: Conducting a Detailed Risk Assessment for Effective SPD Selection

The position and external impacts of the site, including various types of office equipment, combine to establish the basis of adequate SPD sizing. Surge protection systems must be more powerful in areas where there are numerous lightning strikes. The proximity to the power distribution system substations and industrial plants which emit electrical interference increases the chance of surges.

- Power supply features such as voltage and current capabilities require some attention. Surge magnitude information is provided from this data.

- The configuration of the system’s electrical wiring dictates the magnitude and intensity of surges. Certain configurations of long wires increase the chance of the system suffering from surges.

- Knowing the types of appliances that are connected with the system and their sensitivity to voltage fluctuations is very important. Computers, medical devices, and other control systems require more protection from surges than heating systems and general office devices so the latter are considered to be basic equipment.

- Historical surge data from the facility is imperative to take into account when deciding what surge mitigation infrastructure, including protection from telephone lines, to implement.

- Local electrical codes accompanied by industry standards underline various types of installations that require surge protection.

The first risk assessment is guiding in the selection and dimensioning of appropriate surge protective devices; however, the errors in the protection system’s design reasoning will almost always prevent its proper functionality.

Step 2: Choosing the Right SPD Type: Matching Protection to Your Specific Needs

The SPD type selection stems from completing risk assessment. SPDs classification is done based on their position in electrical systems and their protective functionalities. Some of them include the following:

- Type 1 SPDs are devices that operate at the main service entrance subsequent to the main circuit breaker. This style was created to attempt to lessen the effects of extremely high surges that occur as a consequence of lightning strikes on the system or utility switching of electrical loads. Type 1 SPDs are capable of effectively managing largesurge current.

- Type 2 SPDs are protective devices that are placed on distribution panels or sub-panels after the main service entrance. This Type provides protection from remaining surge currents that partially passed through Type 1 SPDs as well as surge currents originated within the facility, including sources of these internal surges.

- Type 3 SPDs are installed near sensitive electronic equipment on the points of use (e.g. power strips with surge protector). These devices provide the highest level of transient voltage surge suppression for low order surges which can escape upstream SPDs, especially when considering the threshold voltage at which they operate effectively.

Choosing an SPD type is a multilayered approach that employs Type 1 SPDs as primary defense, followed by Type 2 and Type 3 devices as secondary shields. The different levels of protective shielding comprehensively safeguard the whole system from various electrical dangers.

Step 3: Decoding Key Parameters: Essential Factors in SPD Sizing

After categorizing the SPD types, the next essential phase is to assign suitable ratings to each device. There are some principal parameters which, after categorizing the SPD types, the next essential phase is to assign suitable ratings to each device. There are some principal parameters which should be taken into consideration with utmost care during the procedure of sizing:

Voltage Protection Rating (VPR) / Voltage Protection Level (Up)

The Voltage Protection Rating (VPR), also referred to as the Voltage Protection Level (Up), is the maximum voltage that an SPD limits to the protected circuit during a surge event. A lower VPR indicates a higher degree of protection. The VPR should be selected based on the voltage withstand capability of the connected equipment. It represents a safe threshold, meaning that surge protective devices will keep the voltage under control if it exceeds a certain limit.

Maximum Continuous Operating Voltage (MCOV) / Uc

The Maximum Continuous Operating Voltage (MCOV), otherwise called Uc, refers to the maximum value of the RMS voltage that a surge protective device (SPD) is able to endure continuously without being damaged or going off accidentally. The MCOV must be above the nominal operating voltage for the system to function properly. Under normal conditions, the device operates in a high impedance state until it exceeds the specified limits. Installing an SPD with too low of an MCOV can result in annoying tripping and/or damage to the device. Under no circumstances should the voltage levels change so dramatically that the device can no longer function normally.

Nominal Discharge Current (In)

The Nominal Discharge Current (In) is defined as the peak value of the surge current that an SPD is designed to withstand multiple times under standardized test conditions (typically 8/20 µs waveform). The In value for SPDs generally ranges from 3 kA to 20 kA for residential and commercial applications, while industrial-grade SPDs may have In values up to 100 kA, verified by testing the SPD as a complete assembly.

Maximum Surge Current (Imax)

The Maximum Surge Current (Imax) is a defined parameter representing the maximum magnitude of a surge current with a specific waveform (typically 8/20 microseconds) that the SPD can withstand once without failure. Imax indicates the SPD’s capability to handle extreme surges, such as direct lightning strikes, which are rarely encountered. A higher Imax rating signifies a greater ability to withstand and dissipate extreme surge energy, as tested under standardized conditions.

Joule Rating

The total amount of energy an SPD Joule rating is designed to handle throughout its lifespan is referred to as its energy rating, and while this rating can give some insight into how well the SPD can provide surge protection, it is not very reliable. Like many other things, the Joule rating is often misused, and by itself, it does not guarantee the SPD will function properly. An SPD’s ability to bear much larger surge events should be more pronounced than simply energy rating, as the aforementioned rating is not the only valuable part. A couple of other parameters which are equal, and in some cases, more important, are In (Nominal Discharge Current) and Imax (Maximum Discharge Current) as they are crucial in assessing SPD’s capability of withstanding numerous surges over a span of time.

Short Circuit Current Rating (SCCR)

To put it simply, SCCR is the maximum short-circuit current that an SPD can endurewithout being damaged when installed and integrated with the device. If no upstream protection exists, the SPD is likely to burst dangerously if the short-circuit current for the installation exceeds the SPD’s SCCR. It should also be noted that for the SPD to function reliably, its SCCR should always be set equal to, or higher than, the faulting current where installation ocurs.

This is a precautionary parameter to ensure that the SPD will withstand the faulty conditions of the electrical system. Due consideration of each of these parameters is vital in choosing an SPD with the proper level for the application and assures protection from surges.

Step 4: Advanced Cascading Surge Protection with Combined SPDs

One surge protection device (SPD) may not be sufficient to safeguard delicate electrical parts from overvoltage. To improve concequence dependability, various tiered types of SPDs are encapsulated into a single unit. With these backbone understanding of fragile electrical parts, LSP aims to offer better surge protection service to all customers. Our products provide different levels of protection by combining Type 1 and Type 2 SPDs, as well as Type 2 and Type 3 SPDs. These pairs take care of considerable power surges at the service entrance and minor surges close to sensitive equipment.

AC System

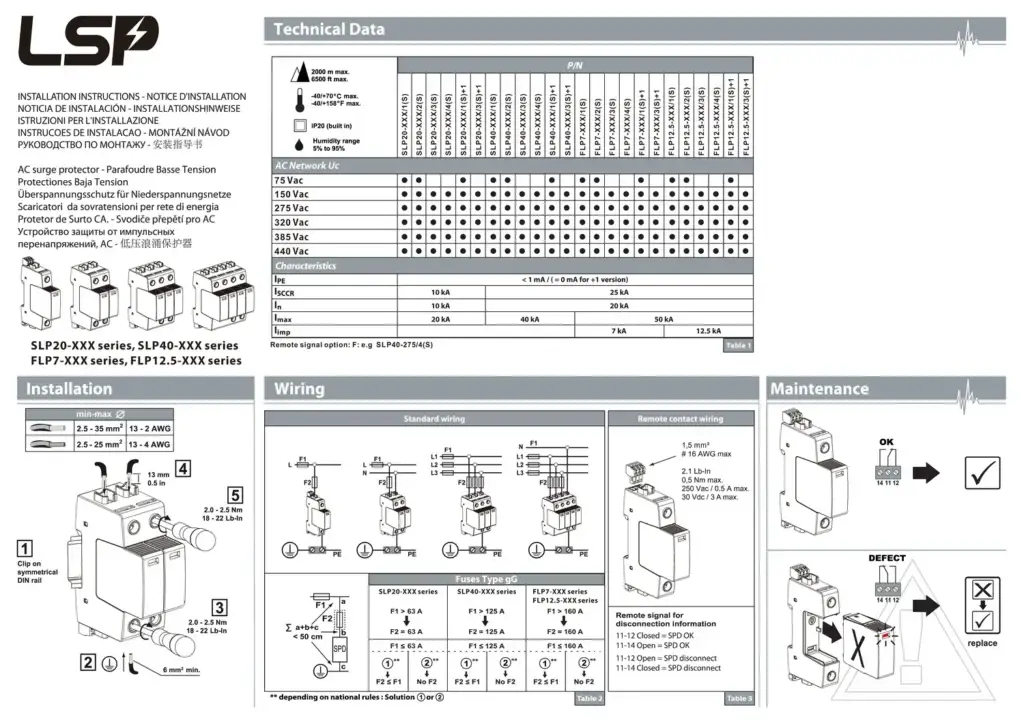

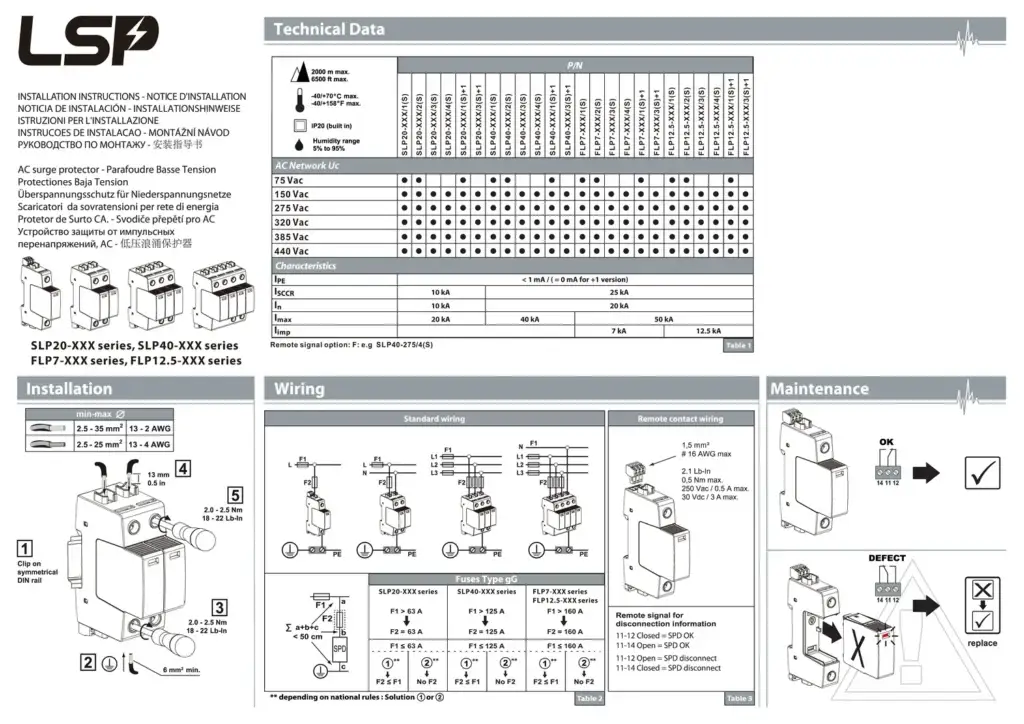

Type 1+2 AC Surge Protective Device FLP7-275/4S

Main Features:

- TUV, CB, and CE certifications

- Three Phase

- High discharge capacity due to heavy-duty zinc oxide varistor

Applications:

- Location of Use: Main Distribution Boards

- Network Systems: TN-S

- Mode of Protection: L-PE, N-PE

- Housing: Pluggable Design

- Compliance: IEC 61643-11:2011, EN 61643-11:2012

Installation Instructions

Type 2+3 AC Surge Protective Device SLP20-275/2S

Main Features:

- Double protection

- Single Phase

- High discharge capacity due to heavy-duty zinc oxide varistor

Applications:

- Location of Use: Sub-Distribution Boards

- Network Systems: TN-S

- Mode of Protection: L-PE, N-PE

- Housing: Pluggable Design

- Compliance: IEC 61643-11:2011, EN 61643-11:2012

Installation Instructions

DC System

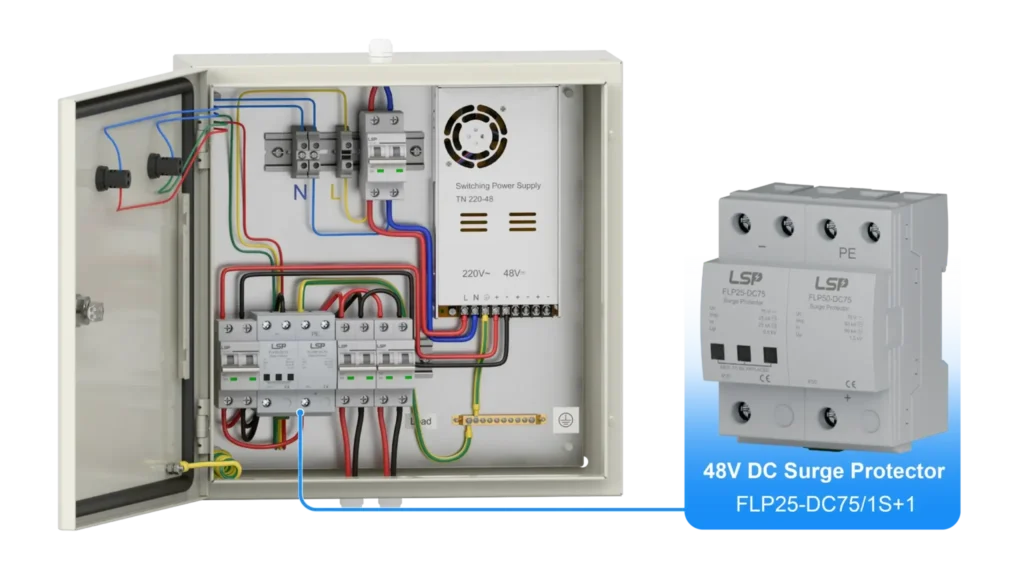

Type 1+2 DC Surge Protection Device FLP25-DC75/1S+1

Main Features:

- DIN rail installation

- For 48V DC power system

- High discharge capacity due to zinc oxide varistor / GDT combination

Applications:

- Location of Use: String box, Inverter

- Mode of Protection: (DC-) – (DC+) and (DC+) – PE

- Housing: Monoblock Design

- Compliance: IEC/EN 61643-41

Wiring Diagram & Installation

Conclusion

An SPD combination of various types mounted in cascade configuration guarantees that the surge protection devices work collectively to protect delicate infrastructure against a wide range of electrical surges. LSP provides you with more surge protector options to better tailor the solution. By better coordinating each type’s functional limits, an organization can achieve an optimum level of protection against damage from transients while extending the asset’s lifetime.

Expert Surge Protection Solutions by LSP: Your Trusted Partner for Optimal Safety

Since 2010, we here at LSP have committed our research and development efforts to the production of high-quality Surge Protective Devices (SPDs). We have a lot of expertise to provide dependable solutions to our customers in over ten countries and an annual capacity of 300,000 units. Our factory covers 1600 square meters and includes two fully automated production lines. We also fulfill certifications likeISO9001, TUV, CB and CE. We take pride in being able to make custom tailored certified SPDs as well as provide certification assistance for clients requiring fast approvals. Every aspect of our business is driven my quality, from using top tier LKD MOVs, Vactech GDTs, reinforced flame retardant plastics, to ensuring durability and performance of the end products.

At LSP, our product advantages are paramount. We not only focus on standard surge protectors but also recognize the importance of Combined SPDs, providing customers with a diverse range of options to meet their specific needs. At LSP, our SPDs have distinct product advantages due to the in-house designed internal tripping device which provides additional safty and moisture protection, as well as Type 2 surge protection (In=20kA, Imax=40kA) and Type 1+2 with dual certification. The additional low-temperature tripping and green board disconnection device helps enhance safty even further. We provide modular designs meeting European and Chinese standards, and sensitive equipment customization even at a modular level. Our quality control procedures follow IEC/EN 61643-11 requirements, which enables us to provide a 5-year warranty on the product. Other than that, we are able to provide full service ranging from expert pre-sales consultation to manufacturing and logistics, and responsive after-sale support with a 12-hour guaranteed response time from any part of the world.

Conclusion: Ensuring Long-Term Equipment Reliability with Properly Sized SPDs

To recapitulate, thoroughly sizing Surge Protection Devices belongs to the area of management and needs concern because it relates to proper peripheral electrical system and sensitive electronic equipment operation for extended periods of time. A well sized SPD is appropriately designed to provide reliable protection against highly unpredictable and potentially damaging transient overvoltage.

A detailed risk evaluation and selection of types of SPDs, as well as analyzing all relevant parameters down to voltage protection rating, MCOV, nominal discharge current, Imax, Joules, and also even SCCR, provides and effective integrated organizational strategy for surge protection. The first step in this process is selecting top tier surge protection devices which guarantees dependability and performance over time.

SPDs do not provide sufficiently optimal protection if they’re maximally sized. On the one hand, undersized devices could fail in high surge situations and over sized ones simply lead to costs without value. Finding a manufacturer who has competence in bespoke design and SPD fitting is vital. LSP is a reliable manufacturer of surge protective devices and as such provides competitively priced high quality SPDs that meets high protection standards and ensure each application gets the right protection level as they guarantee their tailored solutions actually work. With improvement of the known dependency interconnectivity on stable power supply, there’s even greater need for attention to detail when it comes to choosing an SPD. Not paying attention to these specifics allows for the increasing exposure of electrical systems to unpredictable surges and the staggering damage these can lead to.