In our contemporary electric world, the discussion of power is usually reduced to the existence or the lack of it. But there is a more permanent danger in the nature of that power. In any organization that depends on electronic equipment, i.e., all organizations, the risk of electrical surges is not a trifling issue. It is an essential part of continuity in operations, protection of assets, and safety.

This guide does not stop at simple definitions to give a conclusive picture of surge protection. We are going to look at what electrical surges are, the fundamental principle behind mitigating them, the technology that has been created to manage them, and the strategic application necessary to have a strong, professional-grade security system. It is not just to define a product, but to develop a way of thinking about electrical protection as a permanent, essential component of your infrastructure, protecting your sensitive electronics against damage.

Understanding Power Surges and Why They Matter

A stable supply of electrical power is the lifeblood of all modern technology. However, this supply is susceptible to disturbances that can have immediate and severe consequences. The most common and damaging of these are power surges.

What is an Electrical Surge?

A transient overvoltage, more commonly referred to as an electrical surge, is a sudden, brief rise in voltage in an electrical system. North America uses a standard voltage of 120 volts, and Europe uses 230 volts, in a predictable, stable sine wave. This stability is interrupted by a surge that creates a voltage spike that may be measured in thousands of volts. Although such events may only take microseconds, their effects on the microprocessors and parts of the electronic devices may be irreversible.

Such voltage surges are not even. They differ in origin, magnitude, and duration. Others are minor, periodic occurrences that happen inside a facility and wear out internal parts over months or years. Others are large, high-energy events such as a direct lightning strike, which can result in instantaneous and disastrous equipment damage. The harm is not necessarily a dramatic spark, but is frequently a quiet, accumulative process resulting in premature failure, data corruption, and unexplained operational glitches.

Common Causes and Potential Damage

These transient events have external and internal sources.

External Sources: The strongest surges are those that are outside a facility. A lightning strike on or close to a power line may inject a huge voltage and surge current into the grid. Equally, regular switching of the power grid by utility companies creates immense surges that propagate along the transmission lines and into the buildings, impacting all the devices connected to it.

Internal Sources: Most of the large surges are internally produced statistically. Each time a large appliance or heavy industrial equipment with a motor is turned on or off HVAC unit, elevator, or compressor, for example large variation is introduced into the electrical system of the building. The breakdown of the magnetic field of the motor causes a voltage spike that travels through the local circuitry.

In sensitive electronics, any voltage that is higher than its normal operating voltage causes stress. The possible harm is enormous and comprises:

- Catastrophic Failure: The immediate destruction of circuit boards, power supplies, and processors.

- Latent Failure (Degradation): The gradual weakening of electronic components, leading to intermittent faults and a drastically shortened equipment lifespan. This is often caused by smaller, repetitive surges that slowly wear down the protective components inside the device itself.

- Data Corruption: Disruption to logic circuits, such as those in programmable logic controllers, causing errors in data processing and storage.

- Safety Hazards: Overheating of damaged components creates a significant risk of fire.

The Core Principle of Surge Protection

The basic idea behind surge protection is not to stop or absorb the huge energy of a surge, but to redirect it. A surge protective device (SPD) is not a wall against the high incoming voltage; rather, it is a high-speed, intelligent traffic cop to the electric current.

The fundamental idea is to offer a low-impedance path to safely divert the excess voltage and current to avoid the connected equipment. Consider the electrical supply in your wiring as water in a pipe at a normal, accepted pressure. A power surge is an abrupt, huge rise to a greater pressure that would burst the pipe. A surge protector is similar to a pressure-sensitive safety valve.

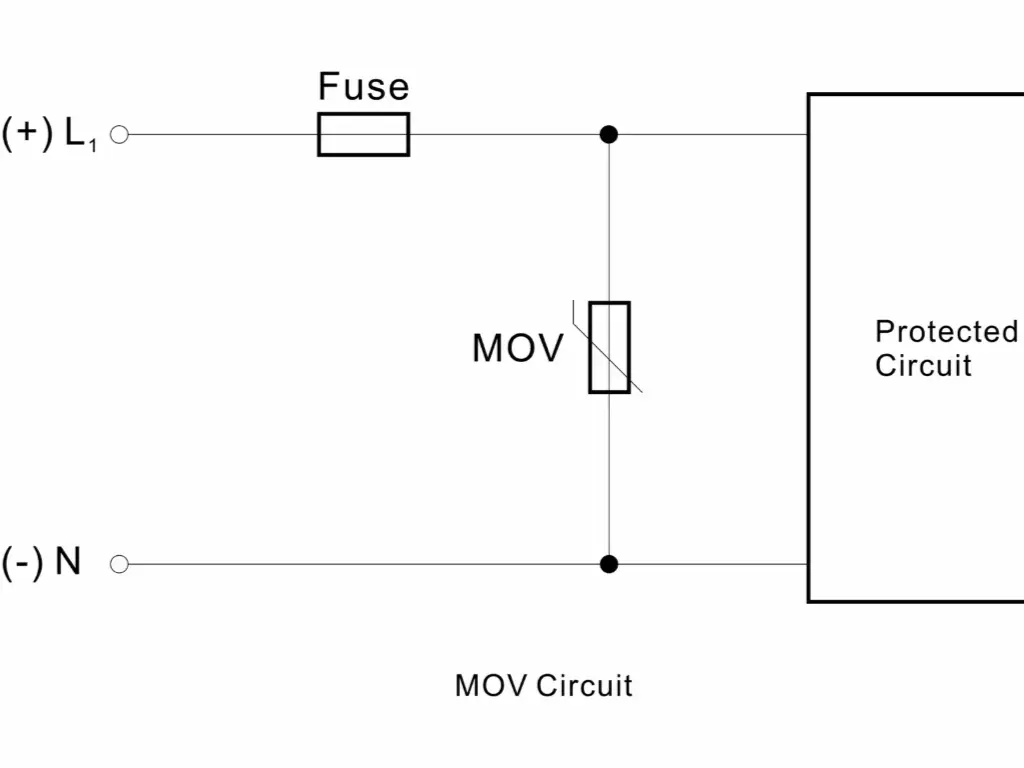

At normal operating voltages, this valve is closed and the SPD is essentially transparent to the electrical system. It opens in a fraction of a second when it senses a voltage spike that is above a certain threshold. This move forms a very conductive, safe path that redirects the hazardous surge current to the ground wire (or ground line). This route enables the excessive energy of the surge to pass around your precious equipment and harmlessly disperse into the ground. When the line voltage becomes normal again, the valve closes and the SPD is prepared to handle the next event. The critical elements that make this rapid switching action possible are key components, including Metal Oxide Varistors (MOVs).

How Technology Delivers This Protection

Metal Oxide Varistor (MOV): The most common AC power protection technology is this solid-state ceramic device. An MOV is made out of a mass of sintered zinc oxide grains. This material provides the component with non-linear, voltage-dependent electrical resistance. The resistance of the MOV is very high at nominal circuit voltages, and a very small leakage current can flow through it. The resistance of the MOV collapses immediately when the voltage across its terminals is greater than its rating, and this provides the low-impedance path needed to divert the surge current. MOVs are appreciated because of their extremely quick response time and their capability to absorb large quantities of surge energy.

Gas Discharge Tube (GDT): A GDT is a passive device that comprises two or more electrodes hermetically sealed in a ceramic or glass envelope, which is filled with a particular mixture of inert gases. The gas is not conductive under normal voltage. When the voltage spike between the electrodes exceeds the breakdown voltage of the gas, there is enough energy to ionize the gas, converting it into a highly conductive plasma. This plasma forms a very low resistance path-an arc- which diverts the surge current to ground. GDTs are able to withstand very high surge currents, and their low capacitance also makes them suitable for protecting high-frequency data and telecommunication lines where signal integrity is paramount.

These are not mutually exclusive components. They are frequently combined in one SPD, with each type taking advantage of its strengths to offer a more effective and dependable protective measure. The technologies are then mounted on a printed circuit board (PCB) along with other required components, including thermal disconnectors to make it safe and indicator lights to show status, and placed in a rugged, fire-resistant housing to form the final physical product called a Surge Protector.

| Feature | Metal Oxide Varistor (MOV) | Gas Discharge Tube (GDT) |

| Response Time | Extremely Fast (< 25 nanoseconds) | Slower (microseconds) |

| Surge Current Handling | High | Very High |

| End-of-Life Mode | Tends to short, requires thermal protection | Tends to open, fails safe |

| Typical Application | AC Power Lines (Type 1, 2, 3) | Telecom, Data, N-PE Bond |

| Capacitance | High | Extremely Low |

| Clamping Precision | Good | Moderate |

Types of Surge Protection Devices (SPDs)

Effective surge protection is a system, not a singular product. It is a coordinated, multi-stage strategy that mitigates transient overvoltages in steps from the building’s electrical entrance down to the individual component. International standards, such as those from the IEC and UL, formalize this approach by classifying SPDs into “Types” based on their intended location and energy-handling capacity. Type definitions may vary slightly between IEC and UL standards, but the functional concept remains the same.

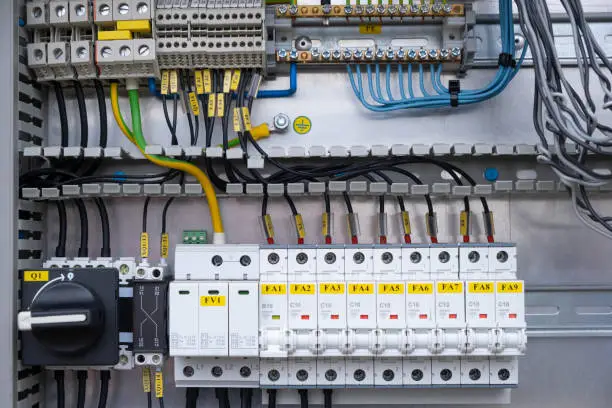

- Type 1 SPD: This is the primary line of defense, installed at the main service entrance, often on the utility side of the main building disconnect. A Type 1 SPD is engineered to handle the high-energy transients from external sources like direct lightning strikes. It is the most robust class of protector, designed to divert the vast majority of the surge energy away from the facility’s wiring. Its function is coarse protection, reducing a massive surge to a level that the downstream system can handle.

- Type 2 SPD: This device is installed on the load side of the main service disconnect, typically at distribution panels and sub-panels. Its role is twofold: it manages the residual voltage let through by the upstream Type 1 device, and, critically, it clamps the internally generated surges created by the facility’s own equipment. The Type 2 SPD is the workhorse of a facility’s protection strategy, safeguarding entire branch circuits that power critical loads.

- Type 3 SPD: This class of device provides point-of-use protection. It is located immediately before the equipment it protects—for example, as a rack-mounted power unit, a specialized plug-in protector, or a device wired directly to a machine’s power input. A Type 3 device has a lower surge current rating but provides the most precise voltage clamping. Its purpose is to clean up any small residual transients let through by the upstream protectors, ensuring the final voltage delivered to sensitive microprocessors is safe.

A comprehensive strategy requires this coordinated chain. A Type 1 device alone will not protect sensitive electronics from damage. A Type 3 device alone will be destroyed by any significant surge. The layered system ensures that surge energy is attenuated in stages, providing a complete defense from the grid to the chip.

Matching the SPD to Your Professional Application

A theoretical framework must be applied to the specific risk profiles and operational requirements of an industry. Understanding is surge protection necessary provides context for aligning theoretical models with practical risk mitigation. To fully grasp this context, exploring what is a lightning protection system

offers essential complementary insights. A generic solution is inadequate for mission-critical professional systems.

For Photovoltaic (PV) and Energy Storage (ESS):

Such systems are very vulnerable. Solar arrays are a large target for lightning and long DC cables are antennas for induced surges. A strong plan needs DC SPDs that are particularly rated for photovoltaic voltages on the combiner box and inverter DC input. At the same time, Type 1 and/or Type 2 AC SPDs are required at the AC output of the inverter to safeguard the inverter and its grid connection.

For Telecom and 5G Infrastructure:

The fundamental goals are continuity of service and data integrity. Although AC power must be protected, the low-voltage data lines are also a weak point to transients. In this case, hybrid protectors, which are a combination of GDT and other technologies, are needed to safeguard Ethernet, coaxial, and other signal lines without compromising signal quality. Type 1 and Type 2 AC protection a basic requirements in exposed cell towers and base stations.

For Industrial and Manufacturing:

The industrial electrical environment is defined by high-energy internal transients. The constant cycling of motors, drives, and welding equipment creates a continuous electrical storm. Protecting the PLCs, VFDs, robotics, and control systems requires a robust, layered defense. Type 2 SPDs at all distribution and sub-panels are the baseline. This must be supplemented by Type 3 SPDs integrated directly into machine control cabinets to safeguard the most critical and sensitive automation components.

Protection as a Permanent Upgrade

- Fire protection design, 5-year warranty

- Top tier raw materials: MOV from LKD®, GDT from Vactech®, etc.

- 300,000 pcs/year

Good surge protection is not a consumable cost; it is permanent infrastructure- a strategic investment in operational continuity and asset protection.

We are in the business of providing these permanent safety infrastructure solutions at LSP. We do this by concentrating on what constitutes long-term reliability. We begin with the best core components in the world, including LKD brand MOVs and Vactech GDTs, so we have a solid base. Then we incorporate custom safety features, such as our “flat disconnector” mechanism, which offers better arc suppression to prevent fire, a fatal weak point in inferior devices.

We test to extremes, such as 10/350us waveform tests that replicate direct lightning strikes. We design our products using industrial-grade materials and demonstrate their longevity, and thus, we are comfortable giving a 5-year warranty. This changes the SPD into a long-term asset, rather than a disposable one, reducing your total cost of ownership and making it a real infrastructure upgrade.

Your Quick-Scan Guide to Selecting an SPD Partner

Choosing an SPD supplier is a critical decision. To navigate this process, you must ask the right questions—questions that probe the true quality and reliability of the product and its manufacturer.

Before committing to a partner, consider the following:

- Component Integrity: What specific brands of MOV and GDT are used, and can you verify their performance specifications?

- Safety Engineering: How does the device’s internal design manage thermal runaway at the end of its life to prevent a fire hazard?

- Verified Performance: Does the device have a valid UL rating (such as per the UL 1449 3rd Edition or later)? Can you provide test reports verifying the claimed clamping voltage and surge current ratings?

- Application Suitability: Does the quoted level of protection match the specific needs of my equipment, whether it’s industrial machinery, telecom gear, or a PV installation?

- Manufacturing Standards: Is your production facility ISO 9001 certified, and what specific quality control tests are performed on every device?

- Long-Term Reliability: What is the product’s warranty period, and does it reflect confidence in a long operational lifespan beyond the industry standard?

- Partnership and Support: Can you provide expert guidance on creating a coordinated protection scheme, and what is your policy on minimum order quantities (MOQ) and customization?

A manufacturer’s ability to provide clear, confident, and detailed answers to these questions is the ultimate indicator of their competence. It separates the providers of disposable commodities from the partners who deliver permanent, professional-grade protection.