A Technical Guide to 3-Phase Surge Protection

Modern industrial and commercial activities require a stable supply of electricity. It is the energy source of heavy machinery to information technology infrastructure. The electrical grid and internal electrical systems are, however, prone to power surges. A power surge, or transient voltage, is a short-lived overvoltage that may degrade, damage, or destroy sensitive electronic equipment.

These are triggered by external causes such as lightning and switching of utility grids and internal causes such as starting and stopping of heavy equipment. Although a surge in a residential environment can be a nuisance, in a three-phase commercial or industrial facility, the same event can cause a substantial loss of revenue due to operational downtime, loss of data, and replacement of equipment. The need for comprehensive surge protection is clear.

The 3-Phase Surge Protection Device (SPD) is the specified device to mitigate this risk. An SPD is an important safety element that safeguards valuable assets. Proper implementation involves proper interpretation of the electrical system of the facility, a systematic selection procedure for all protective devices, and following the right installation procedures. This guide offers a technical basis of comprehending and implementing 3-phase surge protection.

What is a 3 Phase Surge Protection Device and How Does It Work?

A 3-Phase Surge Protector Protection Device is an electrical device that is specifically made to protect equipment that is connected to a three-phase AC power source. Commercial and industrial applications use three-phase systems as they are more efficient than single-phase systems and are therefore used in high-load equipment. While less common, specialized surge protectors for DC power systems also exist for applications like solar or backup power systems.

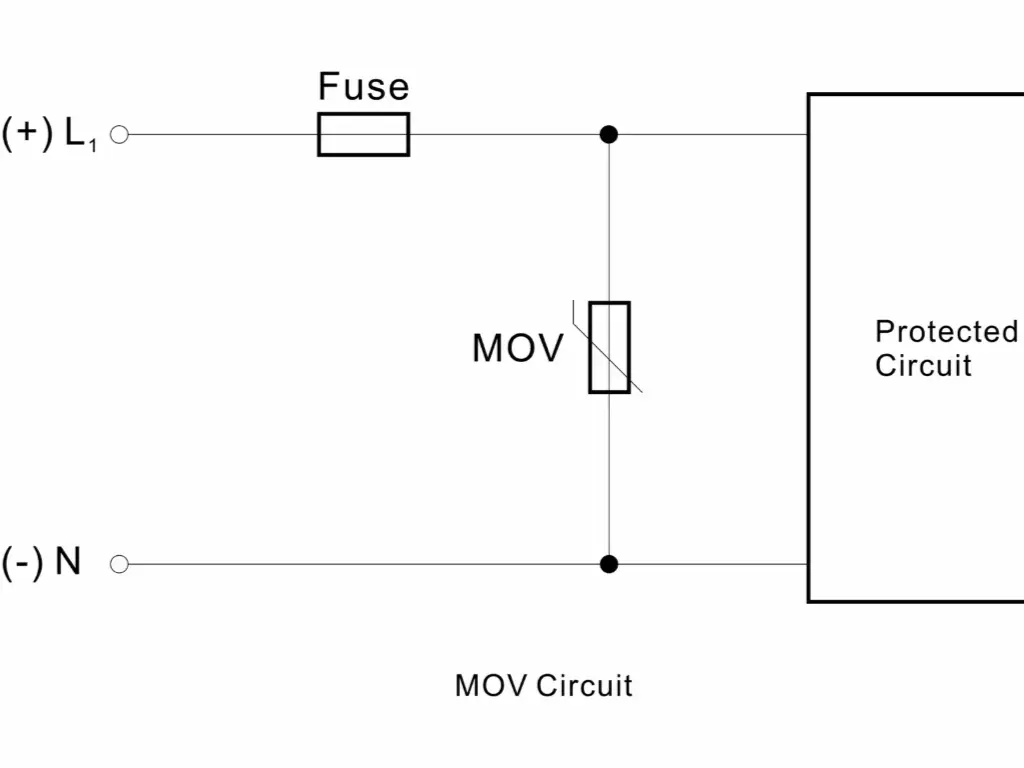

The diversion of excess voltage is the basic working principle of SPD. In normal operation, the SPD is in a high-impedance state. That is, it conducts insignificant current and does not affect the normal functioning of the equipment connected to it. This will make sure that the equipment is still supplied with stable unchanged voltage under normal power conditions.

The SPD responds rapidly when a transient voltage surge arises, which may be due to lightning strikes or switching operations. It has internal components, usually Metal Oxide Varistors (MOVs), which change to a low-impedance state in nanoseconds when the voltage rises above a specific level. This switch enables the surge current to be safely diverted to the ground, avoiding sensitive downstream equipment. When the surge event is over and normal voltage is restored, the MOVs go back to their high-impedance state, and are again prepared to protect against future surges. This quick action and automatic reset feature makes SPDs an important electrical protection system line of defense.

Critical First Step: Identifying Your 3-Phase System

It is important to identify the electrical system configuration of your facility before choosing a Surge Protective Device (SPD). The SPD is effective and safe when it is compatible with the particular system architecture. The two typical 3-phase systems are Wye (Star) and Delta systems in most areas.

- Wye (Star) Systems: This arrangement has three phase conductors (L1, L2, L3) and a neutral conductor, all terminated at a common point. It is a 4-wire system that is widely used in commercial and industrial buildings, particularly where both line-to-line and line-to-neutral voltages are needed. Common uses are lighting, outlets, and general-purpose equipment. A major feature of a Wye system is the existence of the neutral conductor.

- Delta Systems: A Delta system is a three phase system with conductors in a closed loop. They are typically 3-wire systems and lack a neutral conductor. Equipment or processes that only need line-to-line voltages are frequently Delta systems. There can be variations like high-leg Delta or corner-grounded Delta, and each of them has its own SPD requirements.

It is important to know the type of system since SPDs are made to protect certain modes, including Line-to-Neutral, Line-to-Ground, and Neutral-to-Ground. As an example, a 4-wire SPD intended to be used in Wye systems cannot be used in a 3-wire Delta system, and the incorrect type may provide no protection or even cause a safety hazard. To make sure that the SPD is selected properly, it is advised to consult with a qualified electrician or check the electrical one-line diagrams of your facility to make sure that the system is configured properly and then proceed.

How to Select the Right 3 Phase Surge Protection Device: A 5-Step Checklist

Once you have determined the type of your 3-phase system (e.g. Wye/Star or Delta), you should choose a Surge Protection Device (SPD) that best fits the electrical and environmental requirements of your facility. This 5-step checklist will give a clear guideline on how to make the right choice.

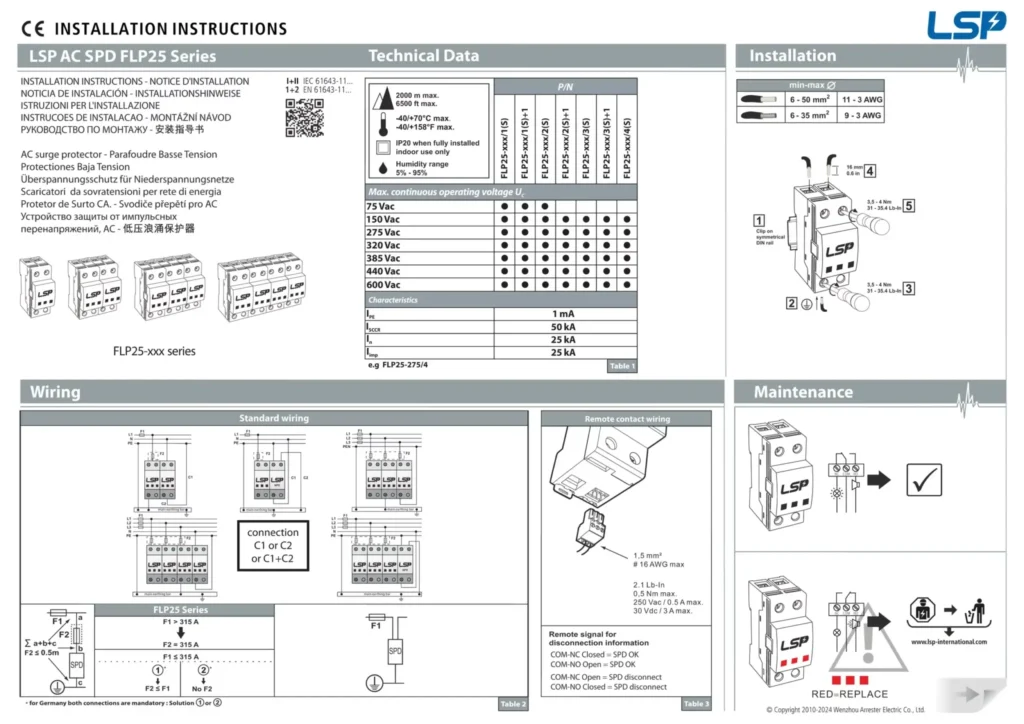

1. Check System Voltage and Configuration

Begin by verifying the nominal voltage and wiring of your system. The 230/400V (Wye) and 400V (Delta) are common voltages in most parts of the world, especially in Asia, Europe, and the Middle East. Ensure that the SPD Maximum Continuous Operating Voltage (MCOV) is normally 15-25 percent above the nominal voltage to provide reliable operation without premature degradation.

Do not use SPDs with MCOVs that are too near the system voltage, because frequent fluctuations or harmonics can damage them over time.

2. Calculate Surge Current Capacity (kA Rating)

The kA rating specifies the amount of surge current that the SPD can safely pass in one event. The choice is based on the place of installation and the lightning environment in the area:

- Main distribution panels or service entrances: In areas where lightning is common or the grid is unstable, consider SPDs rated 100-200kA per phase.

- Sub-distribution panels: Localized protection in office buildings, industrial workshops, or residential towers usually requires 40-100kA per phase.

This rating is not a daily performance, but durability and surge endurance.

3. Test Voltage Protection Level (VPL / Up)

The Voltage Protection Level, also known as Up in IEC 61643-11, is the clamping level in a surge. The smaller the Up value, the safer sensitive equipment such as servers, PLCs, or medical devices are.

Seek devices that satisfy: IEC Category II or III equipment protection

Let-through voltages less than 2.5kV in general applications, or less than 1.5kV in sensitive electronics

4. Choose the Right Type of SPD According to the Point of Installation

SPDs are classified according to where they are to be installed:

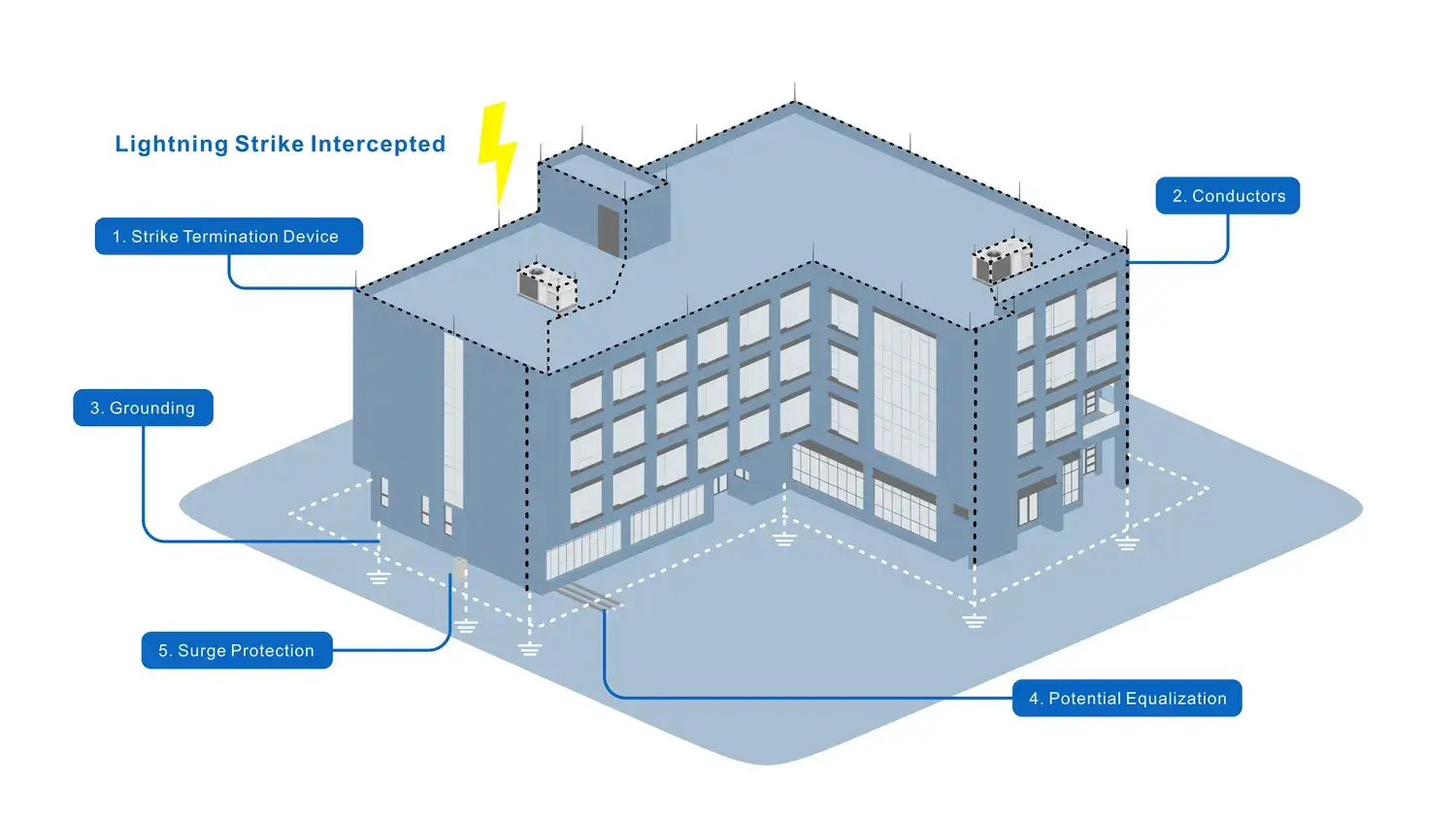

- Type 1: Mounted at the incoming point of the building (prior to the main breaker). Appropriate in locations where direct lightning exposure can occur (e.g., buildings with external lightning protection).

- Type 2: Fitted downstream of the main breaker (distribution boards). Mostly applied in commercial and industrial systems.

- Type 3: Installed close to the equipment (point-of-use). Typical in IT rooms, control cabinets, or sensitive device panels.

Practically, Type 1+2 combination devices are widely used in installations to make the installation easier and provide layered protection.

5. Check Compliance and Safety Features

A good SPD must provide strong safety and operational indicators:

Standards Compliance: Seek compliance with internationally recognized standards including:

- Global benchmark (IEC 61643-11)

- EN 61643 (Europe)

- GB/T 18802 (China)

- Do not use UL 1449 alone, which is North American-centric and might not be applicable in your area.

Status Indicators: The device must have visual indicators (e.g., LEDs) to indicate protection status. More sophisticated models can have audible alarms or remote signal outputs to integrate with BMS.

Enclosure Rating: Match the enclosure of the SPD to the environment:

- IP65 / NEMA 4: Dusty or outdoor locations

- IP20 / NEMA 1: Indoors, clean, dry

Last Tip

Never work in your facility without consulting the electrical single-line diagram and a qualified electrician or electrical engineer. For industrial applications, following a detailed 3 phase surge protection device wiring diagram is absolutely critical. Proper grounding, breaker coordination and matching of SPD type are essential to reliable protection and long term performance.

Proper Installation: The Secret to Effective 3 Phase Surge Protection Device

*We offer a comprehensive installation guide for Three-Phase Surge Protection Devices.

The installation of a three-phase surge protection device (SPD) is not a matter of steps, the success of the SPD is largely determined by the quality of the installation. A correctly rated SPD may not perform well or protect equipment when wiring recommendations are not followed. The following is a detailed, current guide with a focus on best practices and essential installation principles.

Tools and Materials Checklist

- Compatible Three-phase SPD (by voltage level and system configuration)

- Common hand tools: screwdriver, pliers

- Digital multimeter (to check the absence of voltage and continuity test)

- Circuit breaker or fuse (optional upstream protection)

- Electrical safety PPE and insulated gloves

Installation Guide Step-by-Step

1. De-energize the System

Turn off the main breaker or disconnect switch. Check with a multimeter that no voltage is left at the point of installation.

2. Find Key Connection Terminals

Identify:

- Phase terminals: L1, L2, L3

- Neutral (N), as needed by SPD type

- Ground (PE)

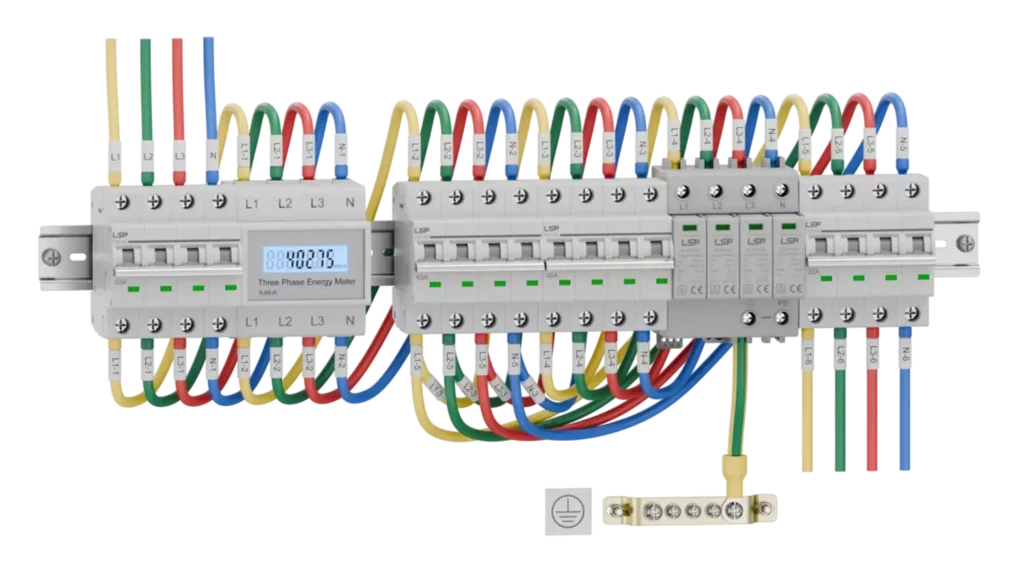

*3 Phase Surge Protector wiring diagram Installation

System Variations: Certain systems (e.g., TN, TT, IT) do not need a neutral connection. Always verify according to system topology and SPD specifications.

3. Optional: Overcurrent Protection

Add protection by installing a circuit breaker or fuse upstream of the SPD. The rating of the breaker should be equal to the handling capacity of the SPD.

4. Install the SPD Near the Main Distribution Panel

Position the SPD as near as possible to the power bus or connection points to minimize the length of the wires. A reduced wiring length does not only make the installation easier, but also makes the diversion of surge energy faster and improves the response time of the SPD.

This leads us to an important point of SPD installation performance: the main limiting factor is the inductance of the wire. Surge currents are high frequency in nature and each inch of conductor adds inductive impedance to the circuit-opposing the flow of the surge current to ground. This increased resistance directly decreases the capability of the SPD to clamp voltage, which may cause damaging energy to reach sensitive equipment.

Golden Rule:

- Make all wiring short, straight, and direct.

- Avoid loops or coils-they greatly multiply the let-through voltage.

- Cut results in the shortest feasible length.

- Where possible, twist conductors to minimize loop area and inductance.

- Make sure that there is a good and low-impedance connection to the building ground.

- Not adhering to these guidelines may permit surge energy to pass around the SPD and reach your equipment-making the SPD useless.

5. Wire the SPD to the Panel

- L1, L2, L3 -> Connect to phase terminals

- Neutral (N) Connect when needed

- Ground (PE) → Bond to the grounding bar on the panel

- Remote Signaling (optional): Connect to a visual/audible indicator or monitoring system where available

- Hint: The SPD can only be as effective as the quality of the electrical path. Surge suppression is undermined by poor or long wiring.

6. Functionality Testing

- Check all terminations again with a multimeter.

- Re-energize the panel and check the status indicators of the SPD (e.g. green light operational).

- Test that any remote alarm or signaling outputs are working.

7. Final Identification & Safety Labeling

Mark the location and wiring of the SPD in the panel clearly. This makes it easy to maintain, upgrade in future or troubleshoot.

Continuous Maintenance & Best Practices

It is important to perform visual checks and observe the indicator lights regularly. Replace the SPD immediately in case of a surge event or when the fault indicator is activated. Also, make sure that the SPD is part of a well-coordinated protection system, including upstream and downstream devices, to prevent unnecessary tripping and full protection.

Conclusion

Adhering to these installation principles, particularly reducing wire inductance and proper grounding, will ensure that your 3-phase SPD operates at optimal performance, and will offer long-term, dependable protection to critical electrical systems.

Common Applications for 3 Phase Surge Protection Devices

Three-phase surge protection can be used in many industries where the work is based on electronic devices. The most important applications are::

| Industry/Application | Equipment/Systems to Protect or Support |

| Manufacturing & Industrial Plants | Programmable Logic Controllers (PLCs), Variable Frequency Drives (VFDs), Motor Control Centers (MCCs) |

| Data Centers & IT Facilities | Servers, Routers, Switches, Uninterruptible Power Supplies (UPS) |

| Healthcare Facilities | Life-support Equipment, Medical Imaging Systems (MRI, CT Scanners), Electronic Health Record Systems |

| Commercial Buildings | HVAC Controls, Elevator Systems, Security Systems, LED Lighting |

| Telecommunications | Cell Towers, Base Stations, Switching Equipment (protection against lightning) |

| Wastewater Treatment Plants | Pumps, Controls, Monitoring Systems |

In all of these applications, the cost of a single surge-induced failure is much greater than the cost of installing a complete surge protection system.

Beyond the Spec Sheet: Why Partnering with the Right SPD Manufacturer Matters

In today’s increasingly complex electrical environments, a 3 Phase Surge Protection Device (SPD) is no longer optional—it’s an essential safeguard for industrial and commercial systems. At LSP, we’ve been dedicated to SPD development and manufacturing since 2010, and we understand that choosing the right manufacturer goes far beyond comparing technical parameters. A truly reliable SPD starts with premium components. That’s why we use LKD-brand metal oxide varistors (MOVs), trusted by the world’s top 10 SPD brands. Our MOVs withstand 8/20 impulse tests at In=20kA (±5 times) and Imax=40kA (±1 time), maintaining stable performance and a service life of over 5 years. For the N-PE path, we rely on Vactech-brand gas discharge tubes (GDTs), recognized by industry leaders like Phoenix Contact. Additionally, all our plastic parts meet glow-wire flame-resistance standards, and our metal parts undergo 48-hour salt spray testing, featuring thicker, corrosion-resistant plating and a larger contact area to handle extreme current surges with confidence.

Beyond components, we’ve spent nearly three years engineering a reliable internal disconnection mechanism that isolates the SPD and extinguishes arcs when MOVs fail, helping to prevent fire hazards. Each SPD is equipped with our signature disconnection device—featuring status window indication, remote signaling, and arc isolation. We’ve also optimized the installation experience: thickened metal terminals, anti-misplugging design, and modular compatibility with both 3+1 and 4+0 configurations—meeting the needs of both European and Chinese markets. These design details ensure that LSP’s 3 Phase SPDs are not only strong on paper, but also outperform others in durability, safety, and ease of use in real-world applications.

We’re more than just a product supplier—we’re your surge protection partner. From customized appearance, packaging, and manuals to laser-engraved or screen-printed logos, we offer full customization. Even for tailor-made models, we can deliver in just one month—well ahead of industry averages. For urgent projects, we also offer stock-based solutions for 10–15 day turnaround. All our products come with a 5-year warranty (while most competitors offer only 2), and our global support team provides remote diagnostics, replacement assistance, and technical guidance. Investing in a high-quality, properly installed 3 Phase SPD is one of the most cost-effective ways to prevent catastrophic equipment failures and costly downtime. If you’re unsure which SPD is right for your facility, or want to learn how our solutions can reduce risk and optimize performance, contact our expert team today for a free consultation—or browse our product lineup to learn more.

Conclusion

A 3-Phase Surge Protection Device is a necessary component of electrical system design and risk management in any modern facility. The threat of transient voltage to microprocessor-based equipment is constant. By following a methodical process of system identification, device selection based on performance metrics, adherence to proper installation standards, and partnership with a reputable manufacturer, a facility can significantly improve its electrical system’s resilience. Implementing these surge protective devices correctly ensures that when a surge event occurs, critical operations and assets are protected.

At LSP, we don’t just manufacture SPDs—we engineer reliability, safety, and long-term value into every unit. If you’re looking for a trusted partner to strengthen your facility’s surge protection strategy, we’re ready to help.