Introduction: Safeguarding Your Investments from the Silent Threat of Power Surges

In an increasingly interconnected world, where our lives and livelihoods are tightly bound to electronic and connected devices, the integrity of our electrical systems has never been more paramount. From sophisticated industrial machinery to the humble home entertainment system, each relies on a stable and predictable flow of electricity. Yet, a silent and often unseen adversary lurks within the electrical grid and even within our own homes: the power surge.

These fleeting but potent bursts of energy—often quantified in joules—can range from minor annoyances to catastrophic events, posing a significant threat to sensitive electronic equipment and systems. The financial consequences of equipment damage, data loss, and operational downtime can be severe, often far exceeding the original cost of the affected devices.

This article underscores the vital importance of choosing the night surge protector. It examines the nature of electrical surges, explores advanced technologies designed to mitigate their impact, and provides practical strategies for implementing effective protection. We will clarify the differences between various types of surge protective devices (SPDs), outline key selection criteria, and share best practices for deployment—ultimately demonstrating that comprehensive surge protection is not just an expense, but a smart investment in the longevity and resilience of your assets.

Understanding Power Surges and Why Protection is Crucial

To effectively combat power surges, it is essential to understand their nature. A power surge, or transient voltage, is a brief but intense spike that far exceeds a system’s normal operating voltage. Though lasting only microseconds, such events can be highly destructive. Unlike voltage sags or prolonged overvoltages, surges are short-lived and unpredictable. They originate from both external and internal sources. External causes include lightning strikes—the, the most dramatic and destructive—which can induce massive voltage transients across the grid. Additionally, utility grid operations, such as switching capacitor banks or large loads, can generate significant surges that travel through the distribution network.

Internal sources, while generally less powerful, are far more frequent and cumulatively damaging. Everyday activities—like the switching of air conditioners, refrigerators, elevators, or even small household appliances—can create localized surges through sudden changes in current flow. These smaller surges may seem harmless individually but, over time, they cause “electronic wear and tear,” degrading sensitive components, damaging circuitry, and reducing the lifespan of devices. Even minor events like static discharges contribute to this slow deterioration, which is often overlooked until equipment begins to fail prematurely.

The impact of unprotected exposure to power surges ranges from minor inconvenience to catastrophic failure. Repeated small surges can lead to frozen screens, corrupted data, erratic device behavior, and eventual component breakdown. On the extreme end, major surges—especially those caused by lightning—can instantly destroy electronics, melt internal parts, and halt operations. For businesses, this can mean costly downtime, lost data, and expensive repairs or replacements. For individuals, it may result in the loss of important files and digital memories. As such, surge protection is not optional—it. It is a critical safeguard for preserving the integrity, functionality, and longevity of both personal and professional electronic assets.

The Core of Protection: Demystifying SPD Types (Type 1, Type 2, Type 3)

The fundamental solution to the threat of power surges lies in the deployment of Surge Protective Devices (SPDs). These devices are engineered to divert excess voltage away from sensitive equipment by channeling it safely to ground, thereby allowing only the normal operating voltage to reach connected loads. Understanding the different types of SPDs and their strategic placement within an electrical system is crucial for comprehensive protection. The International Electrotechnical Commission (IEC) categorizes SPDs into three primary types based on their function and location within an electrical installation—standards that are widely adopted around the world.

| SPD Type | Protection Role | Installation Location | Primary Threats Mitigated | Surge Capacity | Use Case/Benefits |

| Type 1 SPD Your First Line of Defense Against External Threats | First and strongest defense against external surges | At the service entrance (line side of the main disconnect), main distribution panel, or utility pole connection | – Direct and indirect lightning strikes – Utility switching transients | Very high surge current capacity | – Protects entire electrical system from catastrophic external surges – Essential for lightning-prone or critical infrastructure environments |

| Type 2 SPD The Workhorse for Your Electrical Panels | Secondary protection, focused on internal and residual external surges | Inside main service panel, sub-panels, or branch circuit panels | – Internally generated surges (e.g., motor starts, HVAC systems) – Residual external surges bypassing Type 1 SPD | Moderate to high surge current capacity | – Most commonly used SPD type – Whole-house/facility protection – Ideal for residential, commercial, and industrial systems |

| Type 3 SPD Precision Protection at the Point of Load | Final layer of protection near sensitive loads | Close to protected equipment: terminal boxes, control cabinets, DIN rail modules, or embedded at device input | – Low-energy residual surges – Localized equipment-generated transients | Lower than Type 1/2, but high-speed response | – Ideal for sensitive industrial equipment – DIN rail or built-in models used near load terminals – Complements upstream Type 1/2 SPDs in layered architecture |

By strategically deploying Type 1, Type 2, and Type 3 SPDs in a layered approach, you can effectively safeguard your electrical infrastructure against external lightning surges, utility disturbances, and internally generated transients. At LSP, we are committed to delivering high-quality, standards-compliant surge protection solutions that ensure long-term reliability and peace of mind for your critical systems.

Key Considerations for Choosing Your Ideal SPD

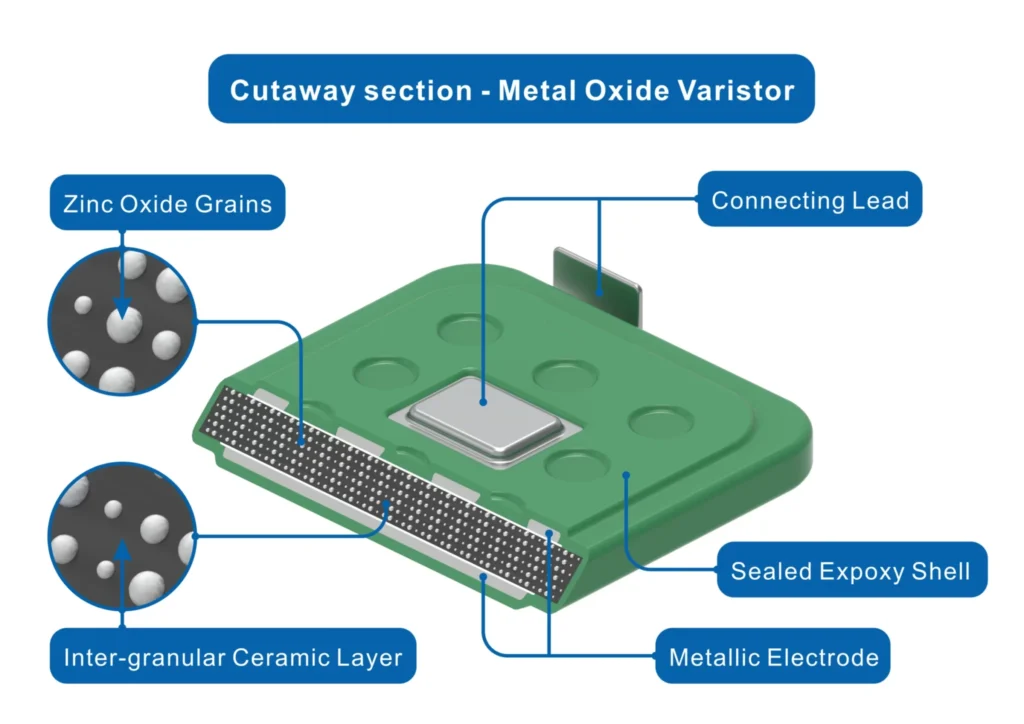

*Cutaway Section Metal Oxide Varistor MOV

Selecting the appropriate SPD requires a careful assessment of several critical factors. A haphazard approach can lead to inadequate protection, leaving valuable assets vulnerable.

- First, Nominal Discharge Current (In) is a crucial parameter. This indicates the peak value of current of an 8/20 $\mu$s waveform that the SPD can safely discharge multiple times (typically 15 times) without degradation. A higher In signifies a more robust device, capable of handling more significant surge events. For Type 1 SPDs, values are often in the tens of kiloamperes (kA), reflecting their role in managing powerful external surges. For Type 2 devices, values are typically lower but still substantial, reflecting their role in internal surge mitigation.

- Second, Maximum Continuous Operating Voltage (Uc) is the maximum AC or DC voltage that can be continuously applied to the SPD without causing damage or degradation. This value must be equal to or greater than the nominal system voltage. For example, for a 230V AC system, an SPD with a Uc of 275V AC or higher would be appropriate. Choosing an SPD with a Uc too low will lead to premature failure.

- Third, Voltage Protection Level (Up), also known as let-through voltage, is perhaps the most critical indicator of an SPD’s protective performance. It represents the maximum voltage that the SPD will allow to pass through to the protected equipment during a surge event. A lower Up value indicates better protection. The goal is to select an SPD where the Up is below the impulse withstand voltage of the equipment being protected. If equipment is rated to withstand, for instance, 1500V, then an SPD with a Up of 1200V would offer effective protection. This is the ultimate measure of how much energy is allowed to “leak” through.

- Fourth, consider the SPD technology. The most common SPD technologies include Metal Oxide Varistors (MOVs), Silicon Avalanche Diodes (SADs), and Gas Discharge Tubes (GDTs). MOVs are widely used due to their cost-effectiveness and high surge current capacity, but they can degrade over time with repeated surges. SADs offer very fast response times and precise clamping, making them ideal for protecting highly sensitive electronics, but generally have lower surge current capacities. GDTs can handle very large surges but have a slower response time and can experience arcing. Often, hybrid designs combine these technologies to leverage their respective strengths, offering superior overall performance. For example, a GDT might handle the bulk of a large surge, while an MOV provides faster, lower-level clamping.

- Fifth, SPD features such as status indicators (showing the operational status of the device), audible alarms, remote signaling capabilities (for integration into building management systems), and thermal disconnects (to safely remove the SPD from the circuit if it overheats) enhance usability and safety. These features provide vital feedback on the health of the SPD and can prevent further issues.

- Finally, applicable standards and certifications are paramount. Ensure that the chosen SPD complies with relevant international standards such as IEC 61643 series (e.g., IEC 61643-11 for low-voltage SPDs), as well as national and local electrical codes. Certification marks from recognized testing laboratories (e.g., UL, CE) provide assurance of quality and safety. Compliance with these standards is not merely a formality; it is a guarantee that the device has been rigorously tested and meets specified performance criteria.

Tailoring Surge Protection to Your Specific Needs: Scenarios and Solutions

Effective surge protection is not a one-size-fits-all solution; it demands a tailored approach based on the specific environment, equipment sensitivity, and financial stakes involved. Different scenarios call for different combinations and types of SPDs.

| Environment | SPD Strategy | SPD Types Used | Additional Considerations |

| Small Office / Retail | Similar to residential setup; focus on protecting business-critical equipment. | – Type 2 at main distribution board – Type 3 at workstations | – Protect computers, POS systems, and network equipment – Consider SPD for Ethernet and phone lines |

| Industrial / Large Commercial | Multi-layered protection is essential; protect both power and control systems. | – Type 1 at service entrance – Type 2 at sub-panels – Type 3 at sensitive loads | – Use for machinery, PLCs, and instrumentation – Redundant SPDs for mission-critical systems – Protect data, sensor, and control lines |

| Data Centers / Server Rooms | Highest level of protection; zero tolerance for downtime. | – Type 1 at utility entry – Type 2 at PDUs – Type 3 at servers/network/storage | – Protect all data lines (Ethernet, fiber) – Use SPDs upstream of UPS units – Apply strict layered defense |

The selection of appropriate SPD types and their strategic placement should always consider the specific electrical characteristics of the system, the criticality of the equipment, the local lightning activity, and the overall budget. Engaging a qualified electrical engineer or surge protection specialist is highly recommended for complex installations to ensure optimal protection.

Why LSP Surge Protection Devices Stand Apart

When asking “What Type of Surge Protection Device Do I Need?”, it’s not just about matching technical specs—it’s about choosing a product that delivers real-world reliability and long-term safety. At LSP, we’ve been focused exclusively on the R&D and manufacturing of surge protection devices since 2010. With over a decade of expertise and exports to 10+ countries, we ensure that whether you’re selecting a Type 1, Type 2, Type 3 SPDor combined SPD, you’re getting a dependable solution. Our 30,000-unit annual capacity and streamlined production process allow us to deliver standard models within 10–15 days and custom units in as little as one month—even under tight supply conditions.

We never cut corners on materials or performance. Our SPDs use top-tier components such as LKD-brand MOVs—used by the world’s top 10 SPD manufacturers—and Vactech GDTs, trusted by industry leaders like Phoenix Contact. Our plastic enclosures are made from enhanced flame-retardant PA6+GF30%, rigorously tested to prevent fire hazards. Internally, our devices feature a proprietary thermal disconnect system, moisture-resistant MOV encapsulation, and superior lighting current endurance. Whether you’re choosing a Type 1 SPD with 10/350 waveform protection or a Type 2 SPD for 8/20 waveform scenarios, our designs ensure strong arc isolation, long lifespan, and consistent performance under real surge events.

Beyond product quality, we offer the flexibility and support to make SPD selection easy and tailored. From personalized labeling and packaging to 3D modeling and custom designs, our team helps you stand out in your market. We also assist with certification (TUV, CB, CE) and ensure complete after-sales care, including a 5-year warranty , 12-hour response time, and global tech support. Our goal is simple: to make sure you don’t just pick the right SPD type—but that you get one you can trust.

Installation Best Practices and When to Call a Professional

* This video demonstrates the AC Type 1+2 Surge Protector Device (SPD) wiring diagram, connection, and installation. At LSP, we provide full technical support to guide our customers through proper SPD replacement and installation.

The effectiveness of any SPD hinges not only on the quality of the device itself but also on its proper installation. A poorly installed SPD can negate its protective capabilities, leaving systems vulnerable. Adhering to best practices is therefore non-negotiable.

- Minimizing Lead Lengths: This is perhaps the most critical installation principle. The wires connecting the SPD to the electrical system and to ground should be as short and straight as possible. Every inch of wire adds inductance, which impedes the SPD’s ability to divert surge current rapidly. Long lead lengths can effectively “choke” the SPD’s performance, allowing higher voltages to pass through before the device can activate. The goal is to create the shortest possible path for the surge current to ground. Think of it as a detour for a rapid river; the shorter and wider the detour, the less resistance it encounters.

- Proper Grounding: An effective ground connection is fundamental. The SPD must be connected to a low-impedance ground path. The grounding electrode system of the building should be robust and meet all relevant electrical code requirements. A poor ground connection means the surge energy has nowhere to go safely, rendering the SPD ineffective. It’s the equivalent of a dam with a porous foundation.

- Coordination and Location: For multi-layered protection, ensure that Type 1, Type 2, and Type 3 SPDs are properly coordinated in terms of their respective voltage protection levels (Up). The upstream SPD (e.g., Type 1) should have a higher Up than the downstream SPD (e.g., Type 2), and so on. This ensures that the bulk of the surge energy is handled by the higher-capacity devices upstream, leaving the lower-capacity devices to manage residual transients. Placement should follow the manufacturer’s recommendations and relevant electrical codes.

- Dedicated Circuitry: Wherever possible, especially for Type 2 and Type 1 SPDs, they should be installed on dedicated circuit breakers. This ensures that the SPD is properly isolated from other loads and can operate without being inadvertently tripped by non-surge related events.

- Environmental Considerations: Ensure the SPD is installed in an appropriate environment, free from excessive moisture, dust, or extreme temperatures that are outside its operating specifications. Enclosures should be properly sealed if the SPD is installed in an outdoor or harsh industrial environment.

- Regular Inspection: Periodically inspect SPDs for any signs of damage, such as discoloration, bulging, or activation of status indicators. Many SPDs have visual indicators (e.g., LEDs, flags) that show whether they are still functional. Prompt replacement of a failed SPD is crucial.

- When to Call a Professional: While some Type 3 SPDs (like power strips) are consumer-installable, the installation of Type 1 and Type 2 SPDs, which involve connection to the main electrical panel and high-voltage wiring, should always be performed by a qualified and licensed electrician or electrical contractor. This is not a task for the untrained. Working with live electrical panels carries significant risks of electrocution and fire if proper safety procedures and electrical codes are not followed. A professional will ensure correct wiring, proper grounding, compliance with all local and national electrical codes, and optimal placement for maximum effectiveness. For complex industrial or commercial installations, consulting with an electrical engineer specializing in power quality and surge protection is highly advisable to design a comprehensive and robust surge protection scheme tailored to the specific needs of the facility. Their expertise can help prevent costly mistakes and ensure long-term reliability.

Proper installation is as critical as the SPD’s specifications. Even the highest-rated connected equipment device will fail to perform if grounding is poor, leads are too long, or coordination is overlooked. Regular inspections and adherence to environmental guidelines further ensure long-term reliability. For any installation beyond simple plug-in connected equipment devices, especially those involving the main electrical panel, the safest and most effective approach is to engage a qualified professional. Their expertise ensures compliance, safety, and peace of mind—turning a good SPD into a dependable line of defense.

Conclusion: Invest in Protection, Secure Your Future

Because we depend on sensitive electronic gadgets more than before, power surges connected to line voltage remain a serious, yet frequently overlooked problem. Brief surges of electricity, whether brought by lightning or from internal equipment changes, can harm or break valuable tools which then causes delays, results in data loss and disrupts operations. Investing in good surge protection is low cost compared to what you might lose if there were no surge protection. This insurance for your electrical system is required, not just an expense you could choose to avoid.

The first step in good surge protection is to familiarize yourself with the different functions of Type 1, Type 2 and Type 3 SPDs. These tools are connected and create a system that defends from the beginning at the service entrance the last monitors near points of use. Nominal discharge current, voltage protection level and the type of internal technology are important factors to ensure an SPD is right for its application. However, getting a surge protector to function well means paying close attention to the way it is connected and grounded, with as little wire length as possible, to help it meet current system security needs.

At LSP, we believe that true surge protection is not only about engineering excellence—it’s about foresight, responsibility, and end-to-end reliability. That’s why we don’t just manufacture SPDs; we design complete protection strategies, from rigorous component screening and multi-step quality testing, to fast, flexible delivery and dedicated global support. Whether you’re outfitting a new system or reinforcing an existing one, we’re here to simplify your decision, shorten your lead time, and strengthen your defenses—because in a world full of electrical uncertainty, preparedness isn’t optional, it’s essential.