Introduction: Why Your Lightning Protection System Is Only Half Complete Without Internal Protection

*This video introduces the basics of lightning protection.

In facility design and electrical engineering, a common misconception is that an external Lightning Protection System (LPS) provides complete protection from the damaging effects of lightning. While air terminals (or strike termination devices), down-conductors, and a propergrounding system are essential components for protecting a structure from direct strikes and preventing structural damage or a fire hazard, they address only one aspect of a comprehensive protection system. Relying solely on an external lightning protection system ignores the significant threat to the sensitive electronic systems required for the operation of any modern building. The purpose of a lightning protection system is to manage all the risks associated with thunderstorms, not just the physical impact.

The reality, supported by data from organizations like the American Meteorological Society, is that a significant amount of lightning damage is not caused by the direct attachment of the lightning channel, but by the secondary effects—powerful electrical surges that are injected into a facility’s power and data lines. These transient overvoltages can damage or destroy a wide range of electronic equipment, from servers and PLCs to office equipment and security systems. The installation of lightning protection is incomplete if it does not mitigate these specific threats. This guide provides a detailed framework for engineers and designers to implement a complete and resilient system by integrating the essential component of internal surge protection, adhering to key safety standards.

Beyond Direct Strikes: Understanding the Threat of Surges

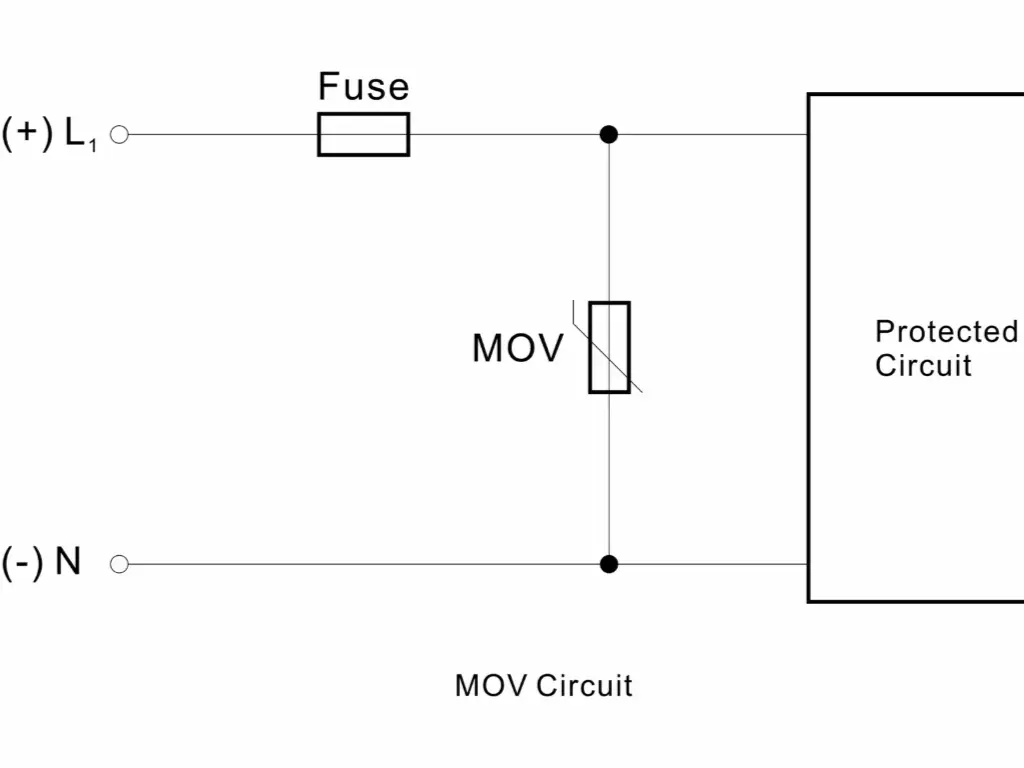

The constraint of an external LPS is founded on the physics of a lightning discharge. When lightning strikes, it discharges a great deal of energy and its impact is not limited to the point of contact. This energy travels in two main ways that may cause damage to the internal systems of a facility: conducted surges and induced surges. The scientific rationale behind the necessity of Surge Protective Devices (SPDs) is the knowledge of these phenomena.

- Conducted Surges: In the case of direct lightning strikes on a building, the outer LPS diverts most of the lightning current to the earth termination system. The process results in a very high and fast rise in the ground potential around the facility, which is referred to as Ground Potential Rise (GPR). This GPR establishes a high voltage potential between the internal electrical ground of the facility and the incoming utility lines (power, data, telephone) which are referenced to a remote ground. This potential difference causes a surge current of high energy into the building via these conductive lines. Also, a lightning strike to the utility lines themselves, even remotely, will propagate along the conductors and into the facility as a direct conducted surge.

- Induced Surges (LEMP): A lightning channel emits a powerful Lightning Electro-Magnetic Pulse (LEMP). This strong magnetic field expands and collapses in microseconds, causing high voltages and currents to be induced onto any metallic conductor that it passes through. It is important to understand that lightning travels on any conductive path; this covers the power and data cabling of a facility within the building, external overhead or buried lines that feed the building, and even extensive metallic systems like plumbing pipes and fittings. The outcome is a strong burst that is produced without direct physical contact with the lightning channel. A shielding external LPS is not effective against the effects of LEMP.

These surges expose sensitive electronic components and electronic devices, which are intended to be used at low, stable voltages, to thousands of volts within microseconds. This may cause instantaneous failure of circuit boards or latent damage that causes equipment malfunctions and premature failure with time. A facility without an internal defense system is vulnerable to such events on its electronic assets.

The Core of Integration: A Framework for SPD Placement and Selection

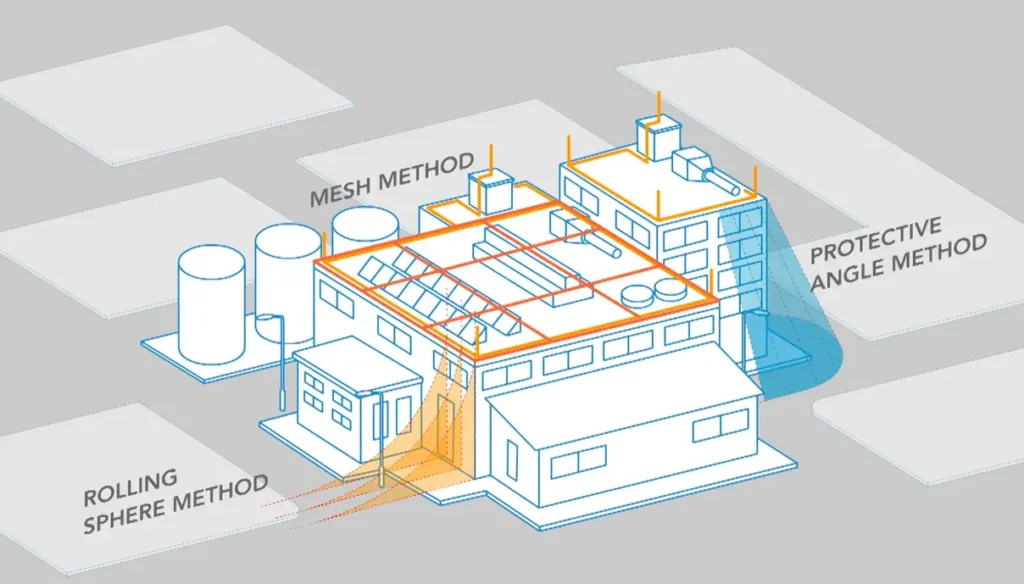

A systematic and engineered approach is needed for effective lightning protection that mitigates these surge threats. This includes the development of a multi-layered, coordinated defense on the basis of international and relevant standards such as IEC 62305. This system is founded on three principles: the concept of Lightning Protection Zone (LPZ), strategic placement of SPDs, and proper selection of SPDs.

The LPZ Concept: Coordinating Protection Zones for Maximum Safety

The concept of Lightning Protection Zone (LPZ) is the principle that should be followed to design an effective internal LPS. It subdivides a structure into a sequence of zones, with each successive zone being a more secure environment with increasingly lower electromagnetic field strengths and surge current levels. The aim is to gradually decrease the surge energy as it moves through a less-protected area to a more-protected area.

- LPZ 0: This is the outer zone, which is directly hit by lightning and the complete LEMP. It is subdivided into LPZ 0A (areas at risk of direct strike) and LPZ 0B (areas not at risk of direct strike due to the external LPS, but still exposed to the entire magnetic field).

- LPZ 1: This is the initial guarded area in the building. The physical structure is the boundary between LPZ 0 and LPZ 1. Any conductive services (power, data) pass this boundary as they enter the building. The initial line of defense is SPDs installed at this boundary, which redirects most of the surge energy.

- LPZ 2, 3, etc.: These are later interior zones. An example is that a general office space could be LPZ 2. An even more sensitive and more shielded location, like a data center or control room, would be an LPZ 3. An additional layer of SPDs is added at the interface between LPZ 1 and LPZ 2 (e.g. at a sub-distribution panel) to further limit the surge to a level that is safe to the equipment in that zone. This cascaded methodology means that when a surge reaches the most sensitive electronics, it has been systematically attenuated to a safe level, providing effective protection.

Strategic SPD Placement: From the Service Entrance to Point-of-Use Devices

The location of SPDs is a rational procedure according to the LPZ concept. An integrated defense must be deployed at three levels of criticality:

Here is the information presented in a table format:

| Location | Boundary LPZ | Description |

|---|---|---|

| Main Service Entrance | 0B -> 1 | The most important point of installation. Requires a main incoming power SPD to handle high-energy lightning currents and redirect the majority of surge energy to ground. |

| Sub-Distribution Panels | 1 -> 2 | Secondary SPDs should be installed at distribution panels supplying sensitive or critical equipment. They handle residual surge “let-through” from the main SPD and surges caused by internal switching. |

| Point-of-Use | 2 -> 3 | Final SPD should be installed as close as possible (within 10 meters) to sensitive or critical equipment (e.g., servers, medical devices). Protects against low-level transients and provides clamping. |

Selecting the Right SPD: Understanding Type 1, 2, and 3 Protectors

SPDs cannot be substituted. They are categorized into “Type” (per IEC standards) or “Type” (per UL standards) which determines their capacity, testing requirements and where they are to be placed in the LPZ system.

- Type 1 SPDs: These are high capacity protectors at the service entrance (LPZ 0B -> 1 boundary). They are subjected to a 10/350µs waveform that approximates the high energy and long duration of a direct lightning current. Buildings with an external LPS or fed by overhead lines must have a Type 1 SPD. It serves to avoid dangerous flashovers and to redirect the primary surge current.

- Type 2 SPDs: These SPDs are intended to be installed at sub-distribution panels (LPZ 1 -> 2 boundary). They are exercised using an 8/20µs waveform, typical of the residual surge energy that is transmitted past a Type 1 device or surges due to indirect strikes and internal switching. They are the most widely used device to protect branch circuits within a facility.

- Type 3 SPDs: These are point-of-use protection devices (LPZ 2 -> 3 boundary) with a low voltage protection level (Up). They possess a reduced discharge capacity and are tested using a mixture of voltage and current waveforms. They should be installed only downstream of a coordinated Type 2 SPD because they are not intended to carry large surge currents. The effectiveness of lightning protection is founded on making the right choice in terms of location and risk.

Conducting a Risk Assessment to Determine Your SPD Needs

Formal risk assessment should be the first step in the design process before any hardware is specified. Failure to take this step when installing SPDs may result in over-engineering (wasting money) or under-engineering (insufficient protection). The IEC 62305-2 standard offers a comprehensive approach to the calculation of the risk of damage as a result of lightning strikes. This risk assessment process, which may involve techniques like the rolling sphere method to determine the required class of lightning protection system, identifies all potential sources of damage and ensures the safety of building occupants.

This test measures several aspects, such as:

- The geographical density of lightning flashes (Ng) of the place.

- The nature of incoming services (overhead vs. underground).

- The physical nature and exposure of the structure, including the risk if it contains flammable materials or explosive materials.

- The existence and nature of an external LPS.

- The importance and sensitivity of internal equipment and operations.

The result of the calculation is a risk value (R) that is compared to a tolerable risk level (RT). When the calculated risk is greater than the tolerable risk (R > RT), protection measures must be taken, such as the installation of a coordinated SPD system. This is a scientific, data-driven method that offers a reasonable rationale to the protection design and makes the investment proportional to the real risk level.

Choosing a Partner, Not Just a Product: The LSP Advantage

- Fire protection design, 5-year warranty

- Top tier raw materials: MOV from LKD®, GDT from Vactech®, etc.

- 300,000 pcs/year

At LSP, we understand that integrating surge protective devices (SPDs) is not just about buying a product—it’s about making a critical decision for safety and reliability. That’s why we go beyond manufacturing. Our expert engineers provide professional consulting, risk assessments, and selection guidance, ensuring every design is fully compliant with international standards. With us, complexity becomes simple.

When it comes to mastering lightning protection system design, SPDs are at the core. LSP helps you master lightning protection system design with SPDs by combining world-class LKD MOVs, Vactech GDTs, and our proprietary disconnection device with moisture-resistant design. Tested to IEC/EN 61643-11 and certified by TUV, CB, and CE, our products deliver lower residual voltage, stronger lightning resistance, and a proven service life of over five years—providing ultimate protection for your critical assets.

Choosing LSP means choosing more than an SPD—you gain a trusted partner committed to your long-term success. We back every product with a 5-year warranty, 12-hour response time, and global customer support including remote troubleshooting, spare parts, and repair services. From design to delivery and long-term operation, LSP ensures your projects run with complete peace of mind. With LSP, you gain not only a product but also confidence and trust.

Common Pitfalls to Avoid in SPD Integration and Installation

Poor installation practices can make even the best-designed system with high-quality SPDs ineffective. The very short rise times of surge currents imply that installation details can have a large effect on performance. Effective systems depend not only on installation but also on selecting reputable surge protection device manufacturers. These are the pitfalls to be avoided:

- Overlong Conductor: This is the most frequent installation fault. The pathway to an SPD should be as direct and short as possible. Each centimeter of wire, often made of copper, contributes inductance (L), and the voltage drops across that wire (V=L*di/dt) during a fast-rising surge can add hundreds or even thousands of volts to SPDs clamping voltage, decreasing its effectiveness. The best practice is that the length of the lead should be less than 50 cm in total.

- Improper Coordination with Overcurrent Protection: SPDs should be coordinated with an upstream overcurrent protection device (OCPD), which can be a circuit breaker or a fuse. Applying an OCPD that is incorrectly rated may cause nuisance tripping during a surge or, more seriously, may not safely disconnect a failing SPD at the end of its life, posing a safety risk.

- Bad Grounding Connections: An SPD works by redirecting surge current to ground. A long or high-resistance ground connection will hinder this action, and instead the surge energy will flow to the protected equipment. The bond to the main earthing terminal, often comprising electrodes or earth rods made of copper-clad steel and driven deep to achieve low resistivity, should be low-impedance, safe and direct.

Key Takeaways for a Resilient and Fully Protected System

In conclusion, electrical system resilience can only be achieved through a comprehensive perspective of lightning protection systems. It is not a set of independent parts but a single, integrated LPS.

- A full Lightning Protection System should include an external LPS using components like masts and air terminals to protect the building and a coordinated internal LPS, with SPDs, to protect the electronic equipment inside.

- An internal LPS must be designed in a systematic manner, in accordance with the Lightning Protection Zones (LPZ) so that the surge energy is dissipated in stages.

- The proper choice and strategic installation of Type 1, Type 2, and Type 3 SPDs is essential to a well-coordinated system that safeguards equipment between the service entrance and the final point of use.

- One of the main factors of performance is the quality of installation. Short lead lengths and adequate grounding are essential to the effective operation of SPDs, as outlined in standards like BS EN 62305.

- The design process should start with a formal risk assessment so that the level of protection is reasonable and justified. The common way of providing operational continuity following a lightning event is an integration of both external and internal protection.