There are systems in our homes that work silently and reliably in the background. We don’t give them a second thought until, one day, they stop working. Your refrigerator, your water heater, the furnace that starts on a cold day. But there’s a system that is even more fundamental to our modern lives: the distribution board.

You’ve probably seen it—a plain metal box, likely tucked away in a closet, basement, or garage. You might know it as an electrical panel or a power distribution board. Yet, this box is the central hub of your home’s entire electrical system. It is the component that stands ready, day and night, to ensure electrical power is managed correctly and safely. Thinking about it can feel complex, as its operation plays a crucial role, and it’s something you should not interfere with unless you are a qualified professional.

But not understanding its function can be a problem. Because when the power supply goes out, or worse, when a dangerous fault occurs, this box and its contents are central to the event. So, let’s have a discussion. A real, direct conversation about your electrical control panel. No impenetrable jargon or technical digressions. Just a straightforward look at what’s inside, why it matters so profoundly, and how to ensure this system is adequate for the task of protecting you, your family, and your home from electrical hazards.

What is a Distribution Board and Why It Matters

*In this video, the basics of distribution boards will be discussed

At its core, a distribution board—and you’ll hear it called many things, from a main panel or fuse box to consumer units in some regions—is the main point for power distribution in your home or building. A large, powerful electrical supply comes into your home from the grid, and the board’s job is to take that main supply and divide it into smaller, manageable currents that feed all your various circuits. One circuit might power the lights in your living room, another the outlets in your kitchen, and yet another your washing machine. This systematic division sends electrical energy to different areas of the property.

Without this division, the full flow of electricity from the grid would attempt to feed every device, an unmanageable and incredibly dangerous situation. The distribution board establishes an orderly and safe network of electrical circuits.

Why It Matters

But its importance goes far beyond simple organization. The primary, non-negotiable role of distribution panels is electrical safety. They are designed as the first line of defense against electrical faults. Every component inside is engineered as one of the system’s protective devices, built to guard against two major threats: overloads and short circuits. An overload is when a circuit is made to handle more power than it’s rated for—like plugging too many high-power appliances into a single outlet. A short circuit is a more serious fault, often caused by damaged wiring, where the electrical current finds an unintended, low-resistance path, leading to a massive and instantaneous release of energy.

In either of these scenarios, the electrical components within your board are meant to react, cutting off the power in a fraction of a second to prevent overheating, fire hazards, and damage to your appliances. It constantly monitors abnormalities. That’s why understanding its internal components and safety features isn’t just for electricians; it’s for anyone who wants a safer home.

The Essential “Core Four” Components

When you open the enclosure’s door (after turning off the main power, of course!), you’ll see a collection of switches and wires. It can look intimidating, but the fundamental anatomy of most modern distribution boxes boils down to four key parts. Let’s get to know them.

Main Switch

The main switch is the primary point of control for the electricity entering the distribution board. Often, this is a large main breaker. It’s usually the largest switch in the panel, often a different color for easy identification. Its job is simple but absolutely critical: it can turn off the entire electrical supply to your home with a single movement.

This is your ultimate manual override. Before any electrical work is done, from replacing a light fixture to a full rewiring, this switch must be turned to the “OFF” position. It physically disconnects your home’s electrical system from the incoming main power supply. For any situation that requires a complete shutdown, this switch is the component you use.

Busbar

Hidden behind the circuit breakers is a component you won’t immediately see, but it’s fundamental to the board’s operation: the busbar. The busbar is a solid strip of conductive metal, typically copper or aluminum, that serves as a central point for distributing the electricity to the circuits. Most boards will have both a live busbar and a neutral busbar.

After the main switch, the live electrical current flows into the busbar. This bar then extends across the board, and each individual circuit breaker connects directly to it. It’s an incredibly efficient method for distributing the main current to all the separate different circuits. The busbar provides a secure and common connection point for all the breakers, ensuring a reliable distribution of power.

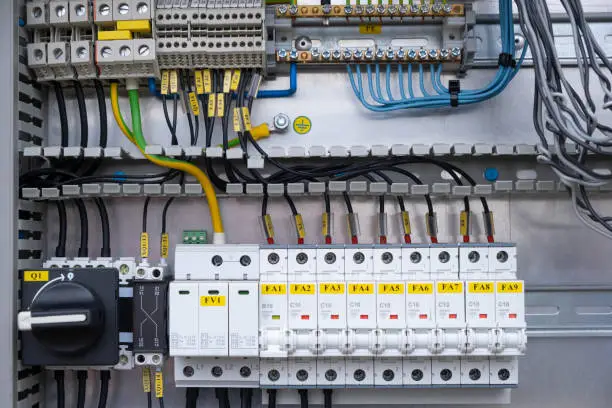

Circuit Breakers (MCBs)

These are the primary protective devices for the individual circuits in your home. The rows of smaller, identical switches in your distribution board are the circuit breakers, most commonly miniature circuit breakers or MCBs. A circuit breaker is responsible for protecting a single circuit, providing both circuit protection and overcurrent protection. For larger installations, you might see a molded case circuit breaker (MCCB) used for higher current ratings.

The MCB is a device designed to perform the function of a traditional fuse, but with more utility. Fuses were a one-time-use device; when they blew, you had to replace them. An MCB, on the other hand, is a switch. When it detects an overcurrent, it automatically “trips,” which means it moves to the “OFF” position, interrupting the flow of electricity to that specific circuit.

The advantage of the MCB is that once you’ve identified and fixed the problem, you can simply reset it. It’s reusable, reliable, and the standard for modern circuit protection.

Enclosure

The enclosure is the metal or plastic box that houses all these vital internal components. It may seem like just a container, but its role is more important than you’d think. The enclosure has two primary functions: protection and containment.

First, it protects the components inside from the outside environment—dust, moisture, and physical damage. It protects against potential hazards that could compromise the system.

Second, and perhaps more importantly, it protects people from the components inside. It ensures that there are no exposed live parts that could cause an electric shock. In the rare event of a fault causing a spark or even a small fire within the board, a well-designed metal enclosure is built to contain it, preventing it from spreading and creating potential fire hazards.

Critical Safety Components: Beyond the Basics

The “Core Four” provide the fundamental framework for a functioning distribution board. But for enhanced safety, both for the people in the house and the ever-growing number of sensitive electronics we own, modern boards include a couple of other crucial devices.

Protecting People: RCDs and RCBOs

Although an MCB is very good at guarding wiring and preventing fires caused by overloads, it is not specifically intended to guard against electric shock to people. The quantity of electricity that may be fatal is much less than the current needed to trip a typical MCB. Enterresidual current devices (RCDs).

The work of an RCD is to identify a particular situation: an electrical current imbalance. The current on life and neutral wires must be equal in a healthy circuit. When a person accidentally contacts a live part, some current passes through the body causing an imbalance. The RCD is extremely sensitive to this and will trip the power very fast to avoid a fatal shock, and is a key part of modern electrical safety.

An RCBO is a combination of an MCB and an RCD in one unit. It guards a circuit against overloads/short circuits and earth leakage. This provides the greatest protection of a single circuit and is commonly applied to certain locations such as kitchens and bathrooms.

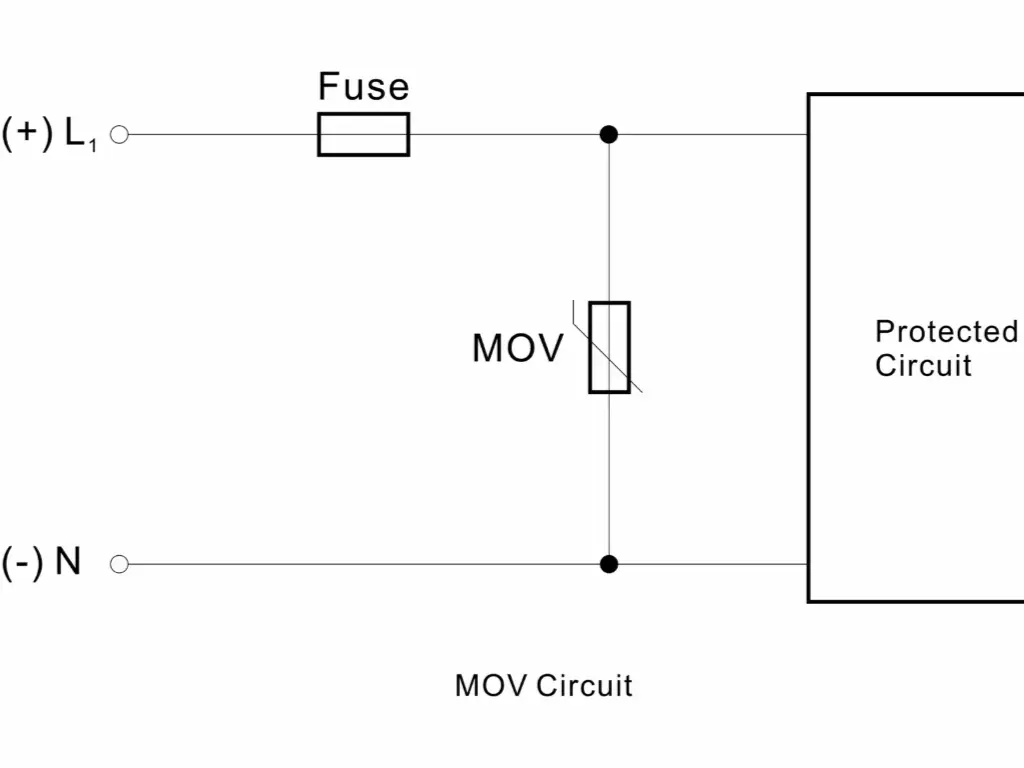

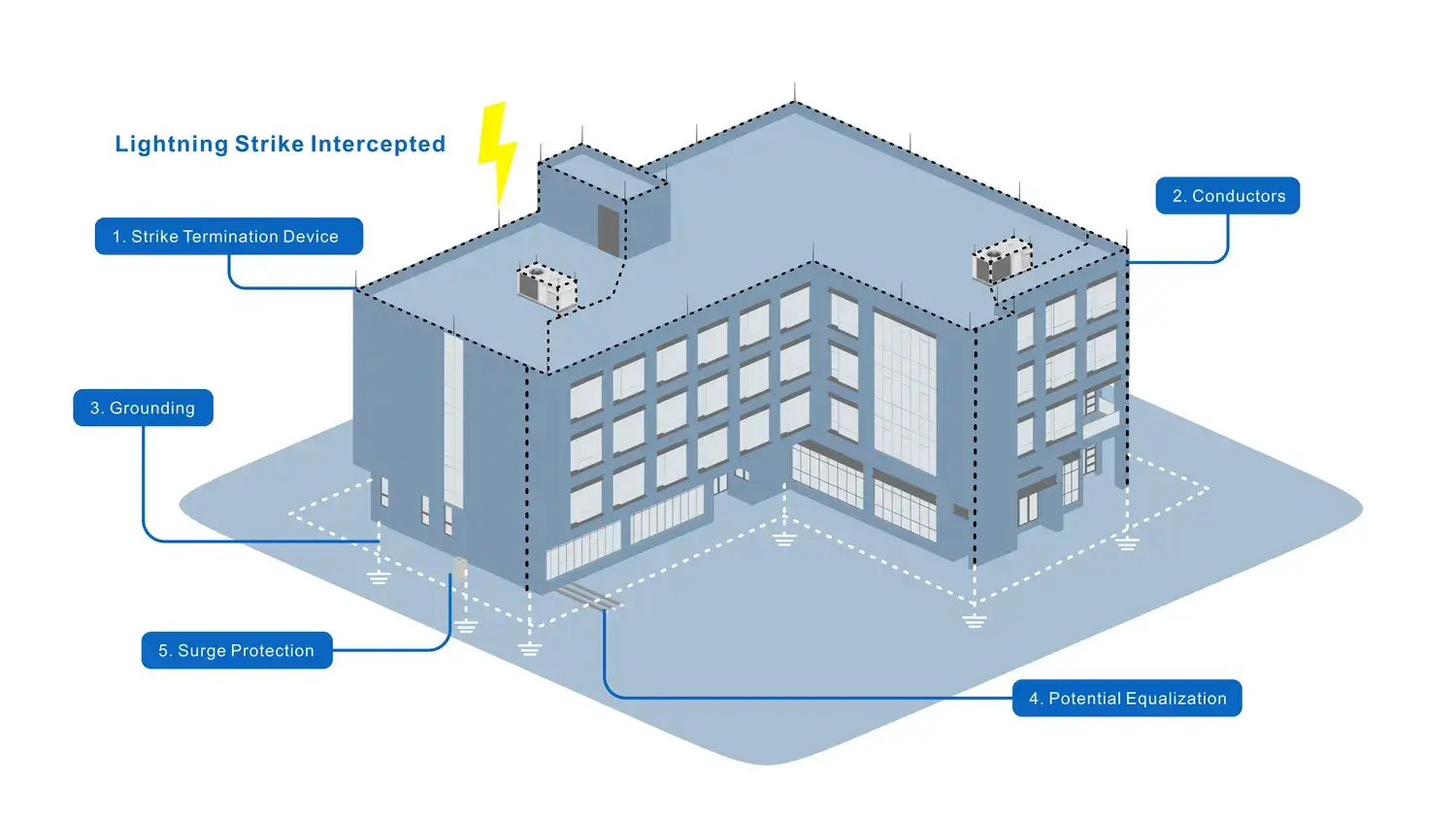

Protecting Equipment: The Non-Negotiable SPD

In today’s interconnected world, electrical surges are a constant threat to your valuable equipment. Whether caused by lightning strikes or internal power fluctuations, these sudden voltage spikes can severely damage sensitive devices like computers, TVs, and other microprocessor-based appliances. A Surge Protection Device (SPD) acts as the “pressure relief valve” for your electrical systems. It safely redirects harmful surges to the ground before they can reach and destroy your equipment. Without an SPD, these surges can go unnoticed until they lead to costly repairs or replacements, making the need for robust surge protection an unavoidable part of modern electrical installations.

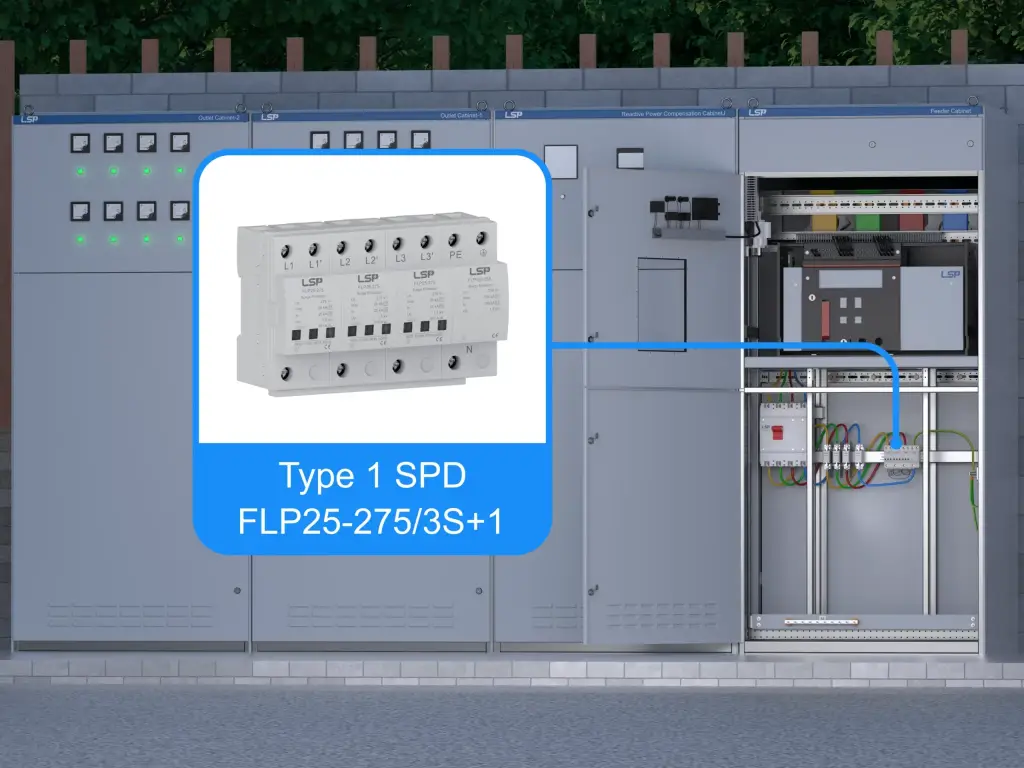

For any building, the distribution board serves as the first line of defense against power surges. This central point controls the flow of electricity into the system, and installing an SPD at this crucial juncture offers the most efficient and economical way to protect the entire electrical set up. At LSP, we specialize in providing SPDs that are specifically designed to integrate seamlessly into your distribution board. By installing a Type 1 or Type 2 SPD at the source of power entry, you ensure that every circuit downstream is shielded from electrical surges, offering complete coverage for the whole building. This proactive approach prevents localized damage and provides comprehensive protection for everything from sensitive equipment to larger appliances.

However, while a standard electrician can install an SPD, selecting the right one requires specialized knowledge, particularly when it comes to protection levels and system coordination. This is where a specialist manufacturer makes a significant difference. At LSP, we have dedicated over a decade to surge protection, designing and manufacturing durable SPDs that comply with IEC 61643-11 standards. Our products are engineered for seamless integration into any distribution board, ensuring the highest level of protection for your entire system. We don’t just sell products; we offer complete safety solutions. By choosing LSP, you’re not only ensuring a hassle-free installation but also guaranteeing that your entire electrical system is fortified against the invisible threat of power surges, protecting your valuable equipment from potential damage.

- Fire protection design, 5-year warranty

- Top tier raw materials: MOV from LKD®, GDT from Vactech®, etc.

- 300,000 pcs/year

How to Select the Right Components for Your Board

Selection of the correct components in a distribution board is an exercise that must always be done by a qualified electrician. It involves sensitive power management considerations and all the components should be properly specified to make the system safe. Future problems can be avoided by proper installation.

| Step | Action | Key Considerations |

| 1. Load Calculation | Perform a thorough load calculation to determine the total amperage requirement of the system. | Accurate calculation of total amperage requirement. |

| 2. Main Breaker Size | Ensure the main breaker size matches the load calculation and allows for future circuit expansion. | Choosing a main breaker that suits both current and future load needs. |

| 3. MCB Selection | Select the appropriate MCBs to be mounted on a standard din rail inside the panel. | MCBs must be properly rated and mounted on the din rail. |

| 4. Compliance with Local Standards | Ensure all components comply with local safety regulations and standards for residential, commercial, and industrial applications. | Regulations vary depending on the type of application (residential, commercial, industrial). |

It is necessary to make sure that every component is selected with the future growth in mind and that they are up to the safety standards. The system will be installed effectively and safely to avoid future issues with a professional installation.

Common Distribution Board Problems and Troubleshooting

Sometimes issues may occur even with the finest parts. Periodic checks may be used to detect the prevalent problems before they cause system breakdowns.

- Tripping Breakers: When a particular MCB keeps tripping, it is an indication of an overloaded circuit.

- Overheating or Burning Smell: This is a serious indication of a potentially hazardous situation and one of the most obvious indicators of wear or a fault. If you observe this, switch off the main switch and call an electrician. This usually means loose connections, a significant source of electrical fires.

- Corrosion or Rust: If there is any moisture or rust on the parts or in the enclosure, that is not good. It implies that the integrity of the enclosure is lost.

- An RCD That Doesn’t Reset: When an RCD trips and fails to reset, it may be a sign of a problem with the wiring itself. This needs a professional to trace and repair.

Your distribution board is not a do-it-yourself project. Although you are able to reset a tripped breaker, any work within the board itself is best left to a licensed electrician. To understand installation risks, see how distribution board vs switchboard systems differ in technical demands.

Your Distribution Board Components FAQ

Let’s end our discussion with some common questions that people have.

Q: What’s the difference between a fuse and a circuit breaker?

A: A fuse is a one-time-use device. A circuit breaker is a mechanical switch that can be reset and reused once the fault is cleared.

Q: My house is old and still has a fuse box. Is that a problem?

A: Not necessarily, but older distribution boxes lack modern safety features and may be undersized. It is highly recommended to have an electrician inspect it and consider an upgrade for enhanced electrical safety.

Q: How often should I have my distribution board inspected?

A: It’s a good practice to have regular inspections by a qualified electrician every 10 years for a home you own, or every 5 years for a rental property, or more frequently for industrial settings.

Q: Can I add a new circuit myself?

A: No. In most places, it’s illegal and extremely dangerous for an unqualified person to add additional circuits to a distribution board. It requires a deep understanding of single phase and three-phase systems, load calculation, and safety regulations.

Q: What does the ‘kA’ rating on an MCB mean?

A: This is the breaking capacity, indicating the maximum fault current the breaker can safely interrupt. It’s a critical safety rating that must be appropriate for your home’s electrical supply.

Q: Why trust a specialist like LSP for surge protection?

A: At LSP, we specialize in surge protection devices (SPDs), with over a decade of expertise in designing and manufacturing high-quality products that protect against lightning and switching surges. Our SPDs use top-tier components like LKD MOVs and Vactech GDTs, trusted by industry leaders. We ensure superior performance through automated production lines, strict quality control, and certifications such as ISO, TUV, CB, and CE.

What sets us apart is our ability to offer customized solutions to meet specific needs, backed by comprehensive testing and a 5-year warranty. From rapid delivery times to excellent after-sales support, we prioritize both quality and customer satisfaction. With LSP, you’re choosing a reliable partner committed to securing your electrical systems.