The solar panel is the visible sign of the progress in the world of renewable energy. It is the part that transforms sunlight into the electricity that runs our modern lives. We marvel at its efficiency, we marvel at its design, we carefully compute its return on investment. However, in the system of wiring and inverters that constitute a complete solar system, there is a critical protective device whose purpose is central to the long-term and dependability of the whole system. This is the DC Surge Protective Device, or SPD.

Ignoring the DC SPD creates a gaping hole in the design of your system. You can have the best panels, the most advanced inverter, and the strongest battery bank, but unless you have proper surge protection against electrical surges, you are putting your investment at a high risk of sudden downtime. A lightning strike, even miles away, or a mere switching event on the utility grid can release a transient overvoltage a high-energy electrical pulse or surge lasting only microseconds that can permanently damage your system.

This is electrical physics and sound engineering. A solar electrical installation with its long cable runs on the DCside is especially vulnerable to picking up these damaging voltage spikes. In this guide, we are going to go beyond a superficial understanding of solar power and into the essential need of surge protection. We are not only going to discuss what a DC SPD is, but how to choose, install, and incorporate it into a complete strategy that will make your PV system safe and reliable throughout its entire expected life. This is the ultimate meaning of a crucial surge protection device that will make sure your harvest of the sun will not be interrupted in the next decades.

What is a DC SPD and Why is it Non-Negotiable for Your Solar System?

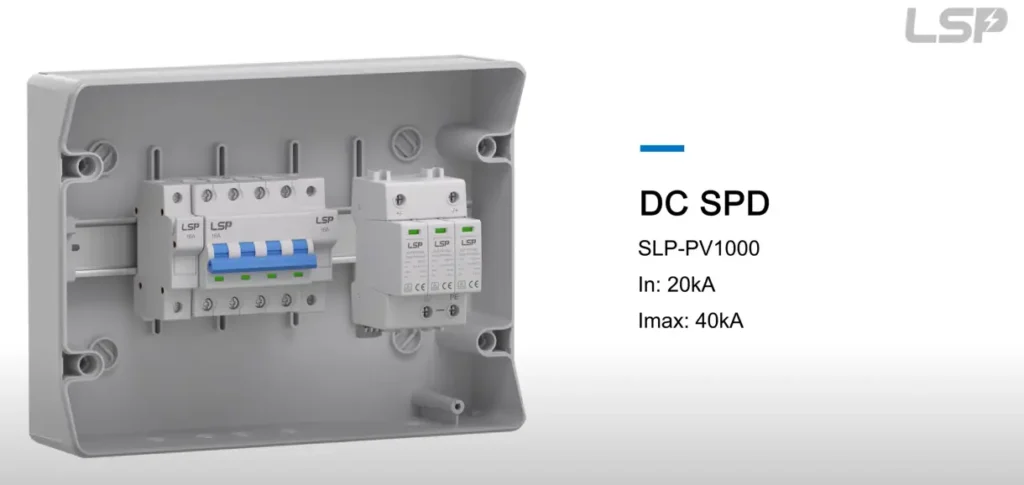

*This video shows how to best use your surge protective devices in solar installations for optimal results.

In essence, a Direct Current (DC) Surge Protective Device is a safety device on the electrical circuit of your solar PVsystem. Its purpose is simple but extremely important: to sense an abrupt, potentially hazardous surge of voltage on the DC side of your installation and, in a fraction of a second, redirect that destructive excess energy to the ground. It does this prior to the surge getting to and permanently destroying the delicate, costly heart of your system, the solar inverter, and other attached electronic devices such as optimizers and battery charge controllers which make up the power supply.

A surge is a sudden, violent rush of electrical energy. The SPD is a pre-engineered diversion channel. It opens immediately to divert the destructive energy away from your inverter and into the grounding system. When the voltage is again at a safe level, the SPD effectively closes, and the circuit resumes its normal, productive operation. The need for such a device lies in the peculiar structure of a photovoltaic (PV) system. The high surface area of the solar array and the long runs of DC cabling between the modules and the inverter provide a convenient route by which voltage surges can be induced. There are two major culprits of these surges:

- Lightning Events: This is the most dramatic and devastating source. A direct strike is disastrous, but even an indirect hit, lightning striking the ground or a building miles away, can cause severe overvoltage on your DClines. All that is required to inject a destructive surge into the wiring is the electromagnetic field produced by the lightning discharge.

- Switching Surges: Less dramatic but much more frequent are switching surges. These transients may be internal, like your inverter or other large appliances switching on and off, or external, coming directly out of the utility grid itself as power is redirected or heavy industrial loads are switched. All these events produce a tiny ripple of overvoltage which, with time, may degrade and ultimately destroy sensitive electronic components.

Your inverter is the first component to be exposed to these threats without a DC SPD. And it is a fight that it is not made to win. The sensitive microprocessors and power electronics within an inverter are designed to operate at specific volts. When they are exposed to the thousands of volts that are in a surge, they will have burnt out circuit boards, a warranty that is voided, and a system that is totally offline until a replacement can be ordered and installed at a high cost. Thus, the DC SPD is not an optional accessory. It is an indispensable element of a professionally developed and robust solar power system. It is among the cheapest things you can do to secure your green energy asset and is a vital part of protecting DC systems.

The Complete Guide to Selecting the Perfect DC SPD for Solar

Choosing the rightDC surge protection device (SPD) is not a game of chance; it involves a technical analysis that is founded on good knowledge of the electrical nature of your system and the environmental conditions under which it is used. To build this foundation, our essential guide on the surge protection device for solar panel is the perfect starting point.

A wrongly chosen SPD can give a false impression of safety-it does not protect when it is needed or can even be a safety hazard. In order to provide efficient protection and reliability of the system, the following main parameters should be taken into account:

- Maximum Continuous Operating Voltage (Uc): This is probably the most important parameter of any DC voltage system. The Uc of the SPD should be greater than the maximum open-circuit voltage (Voc) of the solar string, corrected to temperature. Solar panels produce more DC voltages in colder conditions. You are to compute the Voc at the lowest anticipated ambient temperature at your site. As a rule of thumb, an SPD should be chosen with a Uc that is at least 1.25 times the maximum operating voltage of the system. Selecting an SPD with an insufficiently low Uc can result in it mistaking normal operating voltages as surges, resulting in premature degradation or failure.

- Voltage Protection Level (Up): This is the voltage that appears at the protected equipment following the SPD clamping of the surge. The lower the Up values, the better the protection. Make sure that the SPD Up is significantly lower than the surge voltage tolerance of your inverter, which is usually available in the datasheet of the inverter. As an example, when an inverter has a rating of 2500 V, then an SPD with a Up of 2000 V or lower should be chosen.

- Nominal Discharge Current (In): This rating is the highest surge current that the SPD can safely and repeatedly discharge without damage. It is the capability of the device to withstand frequent, smaller magnitude surges like those induced by grid switching. A nominal discharge current of 15 kA to 20 kA is standard and adequate to most residential and commercial solar applications.

- Maximum Discharge Current (Imax): This is the maximum surge current that the SPD can survive in one event without failure. It shows how the device can withstand severe incidents such as lightning strikes nearby. The greater the Imax values, the longer the operational life. To provide better protection, select SPDs with a rating of 40 kA or more.

- Type of Technology (MOV vs. GDT): The majority of DC SPDs applied in solar systems are Metal Oxide Varistor (MOV) based, which have fast response and high energy-handling characteristics, which are desirable in the high-rising transients in PV systems. MOVs are regarded as the industry standard. Although Gas Discharge Tubes (GDTs) can handle large currents, they are slower and not as well suited to primary protection in PV systems. The best option is a high quality, thermally protected MOV-based SPD, usually supplemented by internal fuses.

- Certifications and Standards (UL, IEC): Do not compromise safety certifications. Make sure the SPD is rated to a recognized standard, e.g. UL 1449 (U.S.) or IEC 61643-31 (international), and that it is rated to the requirements of organizations such as the NFPA. These certifications ensure that the device has been tested thoroughly to be safe, perform, and reliable. There is no need to take a risk by using uncertified equipment.

Step-by-Step Installation: Positioning and Wiring Your DC SPD Correctly

*LSP will guide you through every step of the installation and wiring process, ensuring optimal protection and peace of mind for your solar system.

Installation is equally important as the choice of the SPD. Even a well-defined device may be rendered useless when bad wiring habits are employed. The basic rule is easy: making all connections leads as short and direct as possible. Inductance is introduced by long or coiled wires and this slows the SPD in diverting surges, leading to an increased residual voltage (Up) seen by the inverter.

Positioning

The DC SPD must be mounted in a special, small enclosure, often called a combiner box or DC isolator box, as physically close as possible to the DC input terminals of the inverter. As an example, when you have a string inverter in a garage or utility room, the SPD enclosure must be installed right next to the inverter.

Each centimeter of wire is important. The goal is to prevent surges before they can reach sensitive devices such as the inverter.

Wiring Configuration

Safety First

De-energize the system fully before commencing any work.

- Switch off the PV array DC isolator

- Turn off the inverter

- Turn off the AC breaker that is linked to the inverter

Check that there is no voltage on the DC lines with a multimeter.

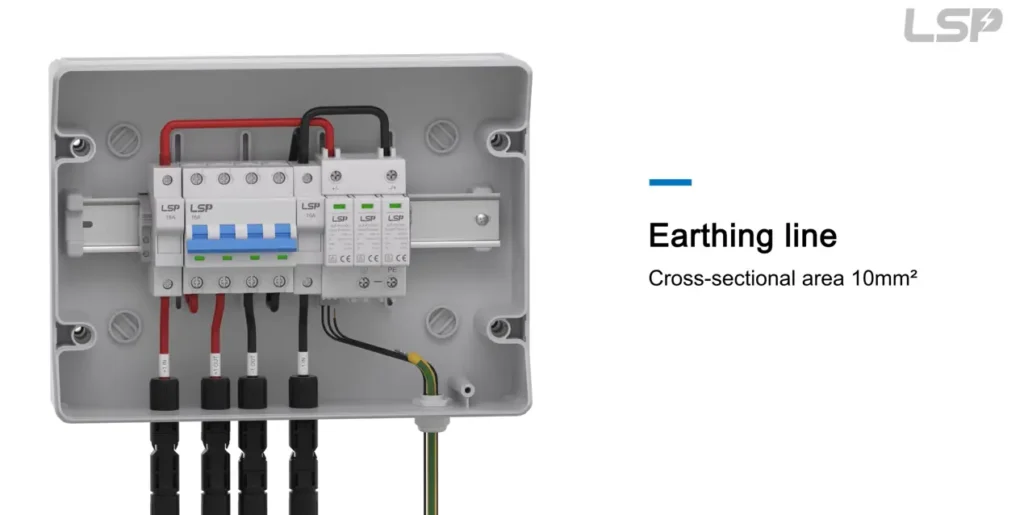

Connect Protective Earth (PE)

The earth (ground) is the first and most significant connection. Connect the PE terminal on the SPD to the main grounding bar of the system.

- Install a conductor of an appropriate rating (usually 6mm 2 or 10 AWG, or greater, depending on local code)

- Make the wire as short and straight as possible

- This is the critical path of safely diverting surge energy and should provide low impedance

Join the Positive and Negative Lines

- Connect the positive DC line of the solar array to the positive (+) terminal of the SPD

- Then connect a wire between the positive terminal of the SPD and the positive DC input of the inverter

- Do the same with the negative (-) line, which goes through the negative terminal of the SPD to the DC input of the inverter

This is referred to as a series connection or Kelvin connection.

Reduce Wire Length

- The overall wiring distance between the DC line, the SPD and the inverter must be minimal, preferably less than 50 cm (20 inches)

- Sharp bends or coiled wires should be avoided since they add inductance

- All conductors should be used in straight and direct lines

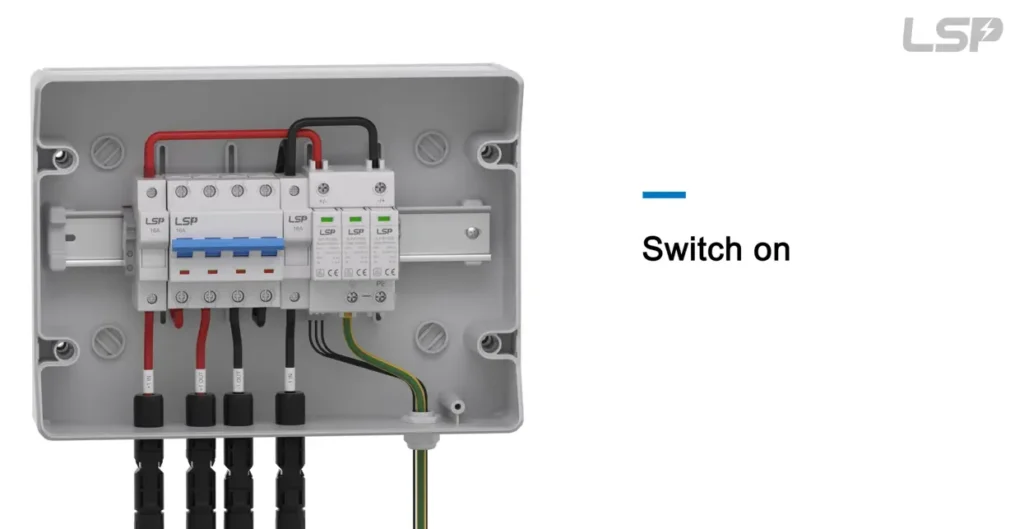

Verification and Testing

- Once all connections are made, check your wiring thoroughly against the manufacturer diagram

- Torque all terminal screws to the recommended values

- Look at the status indicator of the SPD (e.g. green = operational, red or no signal = failure)

- Monitor remote indication contacts, if equipped

After confirmation, re-energize the system in reverse sequence: DC isolator on, inverter on, and AC breaker on.

Beyond the Basics: Building a Robust, Full-System Surge Protection Strategy

One DC surge protective device is necessary, but real resilience is a layered, system-wide surge protection strategy. A surge may get into your system through various ways and a holistic approach considers all of them.

| Layer/Section | Description | Function | Technical Background / Typical Case |

| AC Side Protection | The DC side is particularly vulnerable, but the system is also connected to the utility grid through the AC output of the inverter. Lightning or utility switching can cause surges through the power line that backfeed into the inverter’s AC side. An AC SPD should be installed at the main service panel or in the AC sub-panel supplying the inverter. | Protects not only the inverter but also all electronic devices in the house. | Case: A surge caused by a utility switch operation damaged both the water heater and the inverter’s AC port, both connected to the same line. Proper AC SPD installation would prevent such losses. |

| Array (DC Side) Protection | In systems where the DC cable run between the array and inverter is long (typically over 10 meters or 30 feet), it is recommended to place a second DC SPD in a weatherproof enclosure at the array. | The initial SPD intercepts most of the surge at its origin, minimizing the energy that the SPD at the inverter must handle. This is referred to as cascaded or coordinated surge protection. | Background: Lightning-induced voltage can propagate through long cables, often reaching several thousand volts. A DC SPD at the array reduces the energy that the inverter-side SPD needs to handle. |

| Data and Communication Line Protection | Modern solar systems are networked. Inverters communicate with monitoring portals, optimizers, and battery management systems through Ethernet or RS485 communication cables. These low-voltage communication lines can also be an entry point for surges. Dedicated data line SPDs should be installed on these communication cables. | Prevents surges from damaging sensitive communication ports on equipment. | Case: A nearby lightning strike caused a surge through the communication lines, damaging the RS485 port on the inverter, which required replacing the main control board. |

| Importance of a Good Grounding System | All SPDs work by redirecting surge energy to the ground. If the grounding system (ground rods and bonding conductors) is insufficient, the SPD won’t have a place to redirect the energy, significantly reducing its effectiveness. | Ensures the grounding resistance is low and complies with or exceeds local electrical codes, forming the basis of all surge protection. | Background: IEC recommends grounding resistance should be ≤10Ω. Even with low grounding resistance, failure to perform proper equipotential bonding between different devices can still cause equipment damage due to potential difference. |

Surge protection system is not only devices but also a well-planned and properly installed system. When you add layered SPDs to solid grounding and routine maintenance, you create actual, sustainable resilience in your entire solar system.

Choosing Your Partner: Why a Specialized SPD Manufacturer Matters

Compatible with 600V / 1000V / 1500V DC PV systems

Premium materials LKD® MOV + Vactech® GDT

Internal tripping + low-temperature disconnection

IEC/EN 61643-11 standard TUV/CE/CB certified 5-year warranty

Strong lightning surge endurance passed 8/20 μs & 10/350 μs surge tests

After gaining a deeper understanding of the technical details and importance of Surge Protection Devices (SPDs), you may have realized that choosing a reliable SPD supplier is just as important as selecting the right product specifications. A professional manufacturer does more than just sell products; it also provides in-depth technical support and assurance. As a company with over 10 years of experience in the R&D and production of SPDs, LSP understands how to provide customers with products that meet industry standards while delivering superior performance. We not only offer products that comply with international standards such as IEC/EN 61643-11 but also have an experienced engineering team that can offer professional selection advice based on your specific needs, ensuring that each project receives precisely the protection it requires.

In terms of product technology, LSP‘s SPDs feature advanced MOV technology and our proprietary internal thermal disconnect device, which not only effectively reduces the voltage protection level (Up) but also achieves nanosecond-level response times. This means that when lightning or surges strike, our products can quickly absorb multiple surges, safeguarding your equipment from damage. Especially in the 8/20μs and 10/350μs lightning waveform tests, our Type 1+2 SPDs demonstrate exceptional multiple withstand capabilities and a service life of over five years. These innovative technologies ensure that LSP’s SPDs can maintain stable performance even in extreme environments, providing long-term safety protection for your equipment.

By partnering with LSP, you will benefit from the cost advantages of factory-direct supply and efficient customer service. Our production lines are located in a 1,600 square meter factory with an annual capacity of 300,000 units, enabling us to meet various customer customization needs and offer fast delivery. Whether you require standard products or customized solutions, we can deliver within 10 to 30 days and provide a 5-year warranty, which is significantly higher than the industry standard. By working with us, you will directly receive high-quality products and timely technical support from the factory, ensuring the smooth progress of your project and safeguarding your equipment from surge threats.

Frequently Asked Questions (FAQ) about DC SPD for Solar

Q1: My inverter says it has built-in surge protection. Do I still need an external DC SPD?

A: Yes, absolutely. The “built-in” protection in most inverters consists of small, board-level MOVs designed to handle very minor transients. They are not robust enough to handle the significant energy from nearby lightning or major switching surges. They are a last, often sacrificial, line of defense. An external Type 2 DC SPD is far more robust and is designed to be the primary protector, sacrificing itself if necessary to save the much more expensive inverter.

Q2: How often do I need to replace my DC SPD?

A: An SPD does not have a scheduled replacement interval. It is designed to last for the life of the solar system. However, it will degrade or fail if it is subjected to a very large surge or numerous smaller surges over its lifetime. Most modern SPDs have a visual status indicator (e.g., green/red window). You should visually inspect the SPD at least once a year. If the indicator shows failure (e.g., turns red), it must be replaced immediately.

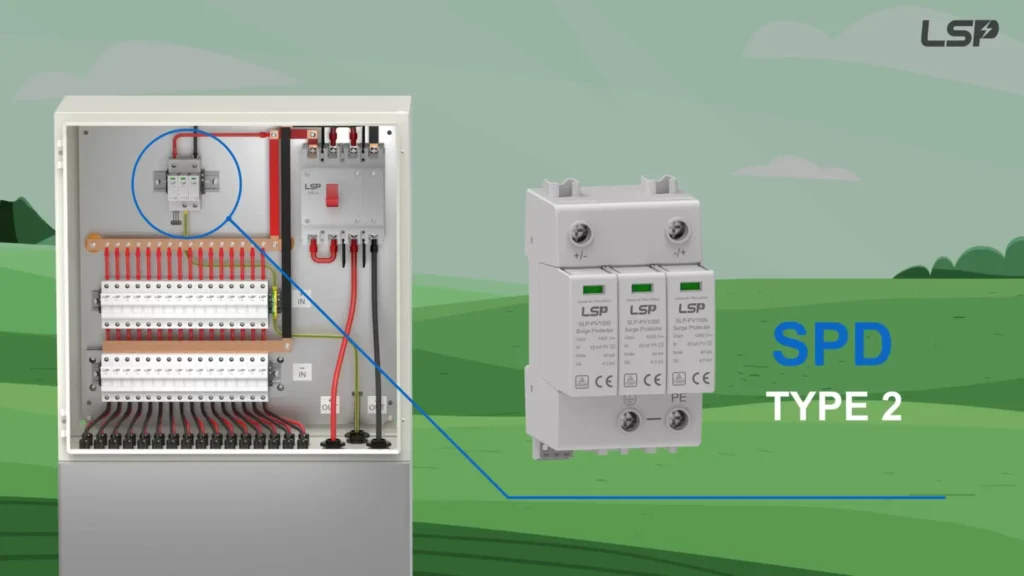

Q3: What is the difference between Type 1 and Type 2 SPD?

A: In simple terms, Type 1 SPDs are designed to be installed at the service entrance and can handle the raw energy of a direct lightning current. Type 2 SPDs are installed downstream, at sub-panels or at specific equipment like an inverter. For most solar installations, a Type 2 DC SPD installed near the inverter is the standard and correct choice. If you are in a very high-lightning-risk area, a coordinated system using Type 1 in the array and Type 2 at the inverter provides the highest level of protection.

Q4: Can I install a DC SPD myself?

A: If you are not a qualified electrician or a certified solar installer with experience working on energized DC systems, you should not attempt to install an SPD yourself. DC electricity from a solar array presents a significant arc flash and shock hazard. The installation must also comply with all local electrical codes. For safety and performance, it is highly recommended to have the device installed by a professional.

Conclusion: Secure Your Solar Future Today

The journey into solar power is an investment in a cleaner, more sustainable future and a step towards energy independence. It is a significant investment of capital and faith in technology. The DC Surge Protective Device is the component that protects that investment. It stands guard against the unpredictable and powerful forces that can threaten your system, ensuring that your harvest of solar energy remains consistent and reliable for years to come.

By understanding its function, selecting the appropriate device with care, ensuring its precise installation, and integrating it into a holistic, full-system surge protection strategy, you elevate your solar installation from a mere collection of components to a resilient, robust power plant. You transform vulnerability into security. Do not let your solar system be disabled by a preventable electrical event. Take the crucial step today to install a high-quality DC SPD and secure the bright future of your solar investment. At LSP, we’re ready to support you with reliable, certified surge protection solutions tailored to your project. Let our expertise and proven performance protect what powers your future.