Introduction: Why Correct 3 Phase SPD Wiring Matters for Your Business

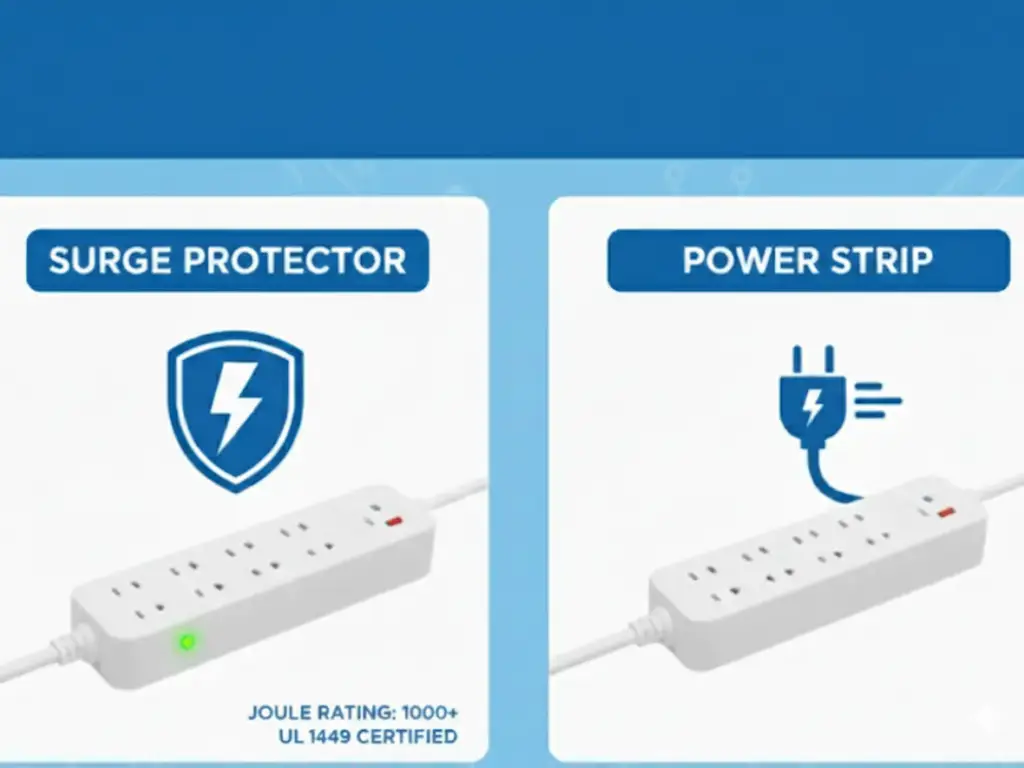

While operating in the current business environment, business functions depend on the use of advanced electronic equipment and hence the stability and quality of electrical power are of primary importance for the integrity of power distribution systems. Even though there are most concerns regarding the reliable supply of current and voltage, the equally important aspect that tends to be overlooked is the protection from transient overvoltages, commonly referred to as surges. Surges are sudden sharp increases in electrical potential that almost always occur randomly and if not checked by a surge protection device or surge protector, can cause expensive damages, equipment failure, data loss, and significant business interruption. Enhanced surge protection against surges, including those potentially caused by lightning strikes, is needed when working with three-phase power systems. Therefore, protected three-phase systems require effective surge protection, specifically involving the circuitry design of the three-phase Surge Protection Devices (SPDs), also known as AC SPDs or protectors.

A power surge is a sudden surge of energy that can violently shake your business and cause significant damage to crucial components like servers, machinery, and communication networks, all of which depend on sensitive electronics. Surge protection devices, such as the three-phase phasesurge protection device, act as electrical barriers, neutralizing the threats posed by power surges to preserve your assets.

But incorrect wiring makes this guardian useless, like a malfunctioning alarm or a broken firewall. Even having an SPD device is not enough; it must perform its critical task, which relies on consideration of meticulous wiring that appropriately integrates the SPD into the electrical system according to safety standards. This article will explain the relevance of each component and outline the three-phase SPD wiring’s best practices to protect your business from surges and ensure adequate lightning protection. Oversights in this regard are putting unprotected risks against the operational efficiency and monetary assetsof the corporation, highlighting the critical protection needs of installations.

Decoding the 3 Phase Surge Protection Device Wiring Diagram: Key Components Explained

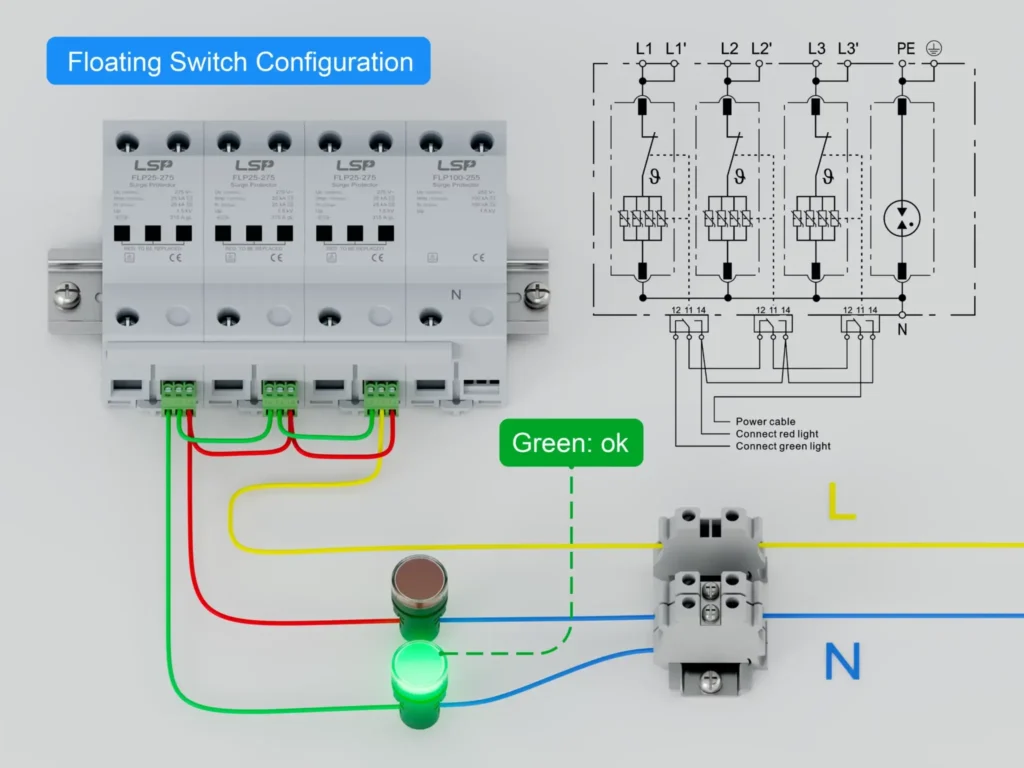

Many components come into play when wiring a three-phase SPD, and knowing them makes the whole process easier. In this case, the wiring diagram that was provided alongside your SPD is not just an abstract schematic; it shows the proper way how each component should be connected and provides instructions for achieving the maximum level of protection in surge protection.

Understanding the L1, L2, L3, Neutral (N), and Protective Earth (PE) Terminals

In a three-phase SPD connection, the power supply phases are labeled accordingly L1, L2, and L3. Each phase has a specific Alternating current. The majority of systems feature an N conductor as well, which releases any imbalance within the system by neutralising unbalanced loads. The SPD possesses a terminal for neutral connection. It provides protection for phase to neutral surge.

Defining the device’s outer, earth ground connection: the Protective Earth (PE) terminal is important for strategically defining the outer earth ground of the device. It provides an efficient low impedance path for surges and fault LV and lightning after RAM currents. PE is crucial because without this connection, energy from surge cannot adequately be dispersed divert surge energy.

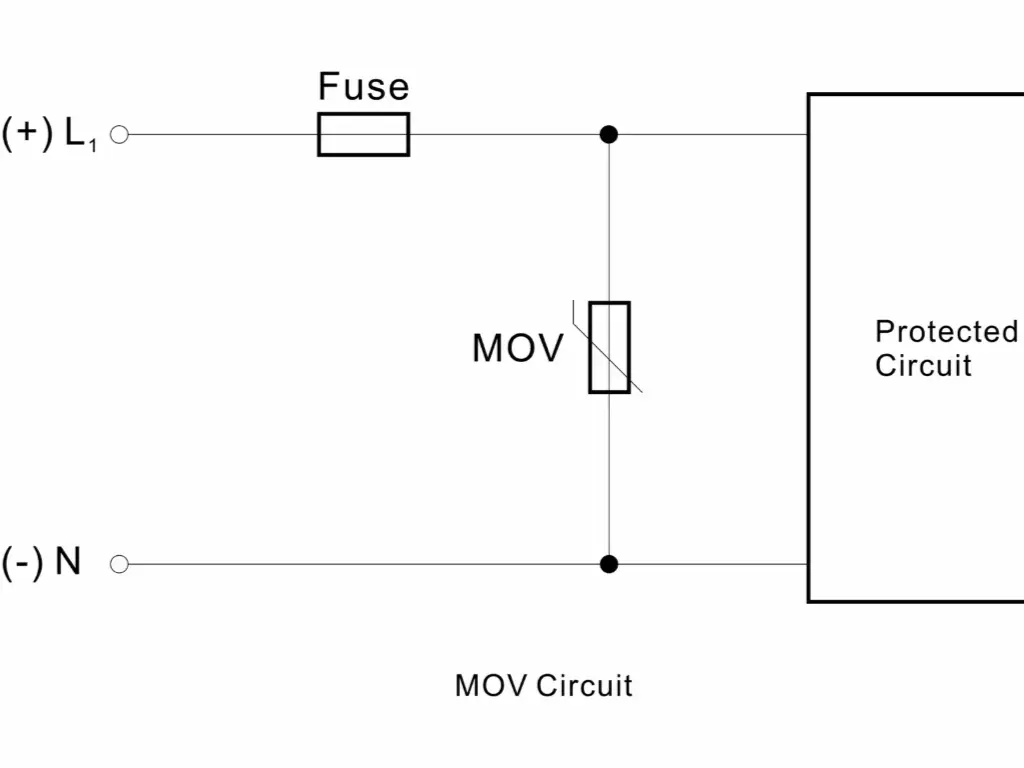

The Essential Role of Accompanying Circuit Breakers and Fuses

Surge currents are capable of being handled by the SPD but overcurrent protective devices such as circuit breakers alongside fuses serve an essential role in guarding the equipment. Usually the Mount these devices in series with the SPD interface. They do not directly withstand the surge but rather stop exceeding follow current from being too much. If the SPD does not clear the fault, the breaker will cut off the following current. In doing so, SPD systems harm both The and damage.

Equipments such as surge protective devices and circuit breakers are crucial in the context of managing surge relations and energy dissipation. Correct choice of these components together with precise system drawings is fundamental for the best type of surge protection. Correct electric isolation is also one of the requirements in the field of safety engineering.

Step-by-Step Guide: Mastering the 3 Phase SPD Wiring Process

Installing a three-phase surge protection device (SPD) requires careful attention to safety standards, the type of installation, and the correct wiring process. Here’s a step-by-step guide for installation:

Tools and Materials Needed:

- Three-phase SPD (appropriate for the application and voltage level)

- Screwdriver and pliers

- Multimeter for voltage and continuity checks

- Circuit breakers or fuses (if needed)

- Insulated gloves and other personal protective equipment (PPE)

Step-by-Step Installation:

| Step | Description |

| 1. Turn Off Power | Safety first: Disconnect the power to the main breaker before performing any electrical work. Use a multimeter to ensure that the power is completely off at the installation site. |

| 2. Identify Connection Points | Identify the phases (L1, L2, L3), neutral (N), and ground (PE) terminals in the distribution panel. The 3 phase surge protection device will need to be connected to all three phases and the neutral (if applicable). Some installations may require a connection only between phases and ground (depending on the system type: TT, TN, or IT). |

| 3. Install Circuit Protection (Optional) | Install a circuit breaker in front of the 3 phase surge protection device for additional protection. Ensure that the breaker rating corresponds with the current handling capacity of the 3 phase surge protection device. |

| 4. Mount the 3 Phase Surge Protection Device | Install the 3 phase Surge protection device near the main distribution board to minimize the lead length between the 3 phase surge protection device and the connection points. Shorter lead lengths improve the effectiveness of the 3 phase surge protection device by reducing response time to surges. |

| 5. Connect the 3 Phase Surge Protection Device to the Panel | Phase Wires (L1, L2, L3): Connect the three-phase inputs from the power system to the respective terminals on the SPD (L1, L2, L3). Neutral (N): If your 3 phase surge protection device is designed for neutral, connect the neutral wire from the system to the SPD’s neutral terminal. Ground (PE): Connect the ground terminal of the 3 phase protection device to the grounding system of the panel. |

| 6. Test the Installation | Verify connections with a multimeter to ensure there are no loose wires or shorts. Turn on the power and check that the 3 phase surge protection device is functioning correctly. Many SPDs have an indicator light to show if the protection is active. |

| 7. Label the Installation | Clearly mark the SPD’s location on the panel for future reference. This is important for maintenance and safety purposes. |

Important Considerations:

- Lead Length: Shorter connection leads from the surge protection device SPD to the panel reduce the chance of voltage buildup during surges.

- Coordination: Ensure the surge protection device is properly coordinated with upstream and downstream protective devices to avoid unnecessary tripping.

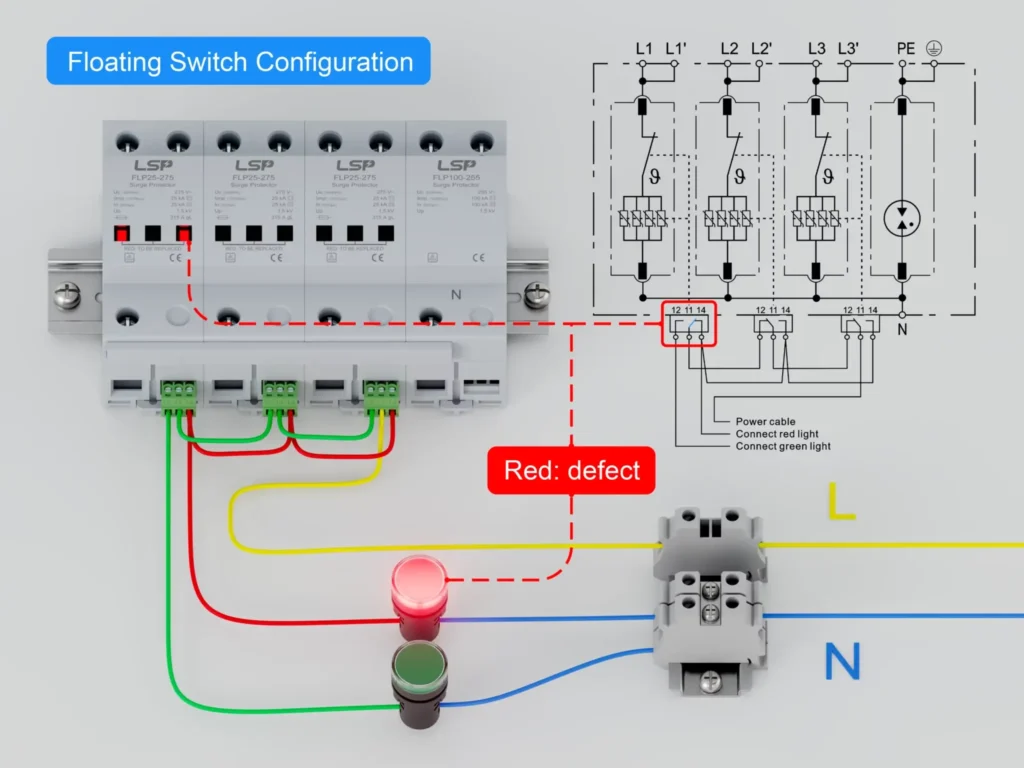

- Maintenance: Regularly check the SPD’s status indicators, as shown in the wiring diagrams. The green light indicates normal operation, while the red light signals a defect. Replace the SPD after a significant surge event, if necessary, to ensure continued protection.

Following these steps will ensure that the 3-phase SPD is installed correctly and effectively protects against overvoltage or transient surges.

Navigating Different 3 Phase System Wiring Configurations and Their Impact on SPD Connections

The way a three-phase electrical system is configured, particularly the earthing arrangement, significantly influences how an SPD should be connected. Understanding these different configurations is crucial for ensuring effective surge protection. The most common configurations are TN-S, TN-C, and TT systems, all of which have implications for lightning protection as well.

TN-S System Wiring: A Common Configuration and SPD Hookup

Because of its earthing arrangement, the three-phase electrical system has a particular way of functioning that influences how an SPD should be connected. These surge protection methods need to be understood in case their configuration lacks proper protection systems intended for electric surges. The most widespread configurations include the following: TN-S, TN-C, and TT systems.

A TN-S system has separate neutral and protective earth (PE) conductors serving all system sections. The source of supply is earthed and neutral and earth conductors are sent out to every installation separately.

In a TN-S system, neutral (N) gets SPD connected to it alongside protective earth (PE). SPDs for such systems are installed between every phase (L1, L2, L3) and neutral (N). Modifications of the emerging configuration offer defense against common-mode surges. The configuration will block a surge on either the phase conductor or on one of the phase conductors balanced with differential mode surges, offering active effective blocking strategy enabling blockage through between phases or between phase and neutral. The clear earth conductor gives good strip down paths for the surge currents enabling current diversion away from the protected system. This configuration adheres to safety standards.

TN-C System Wiring Understanding and SPD Integration

Protective earth’s (PE) role in a TN-C system is combined with neutral and serves the system as a single line parade within sign as PEN conductor. Because of safety standards concerns, clad wiring configuration is uncommon with new wiring installations in modern times.

Connecting an SPD in a TN-C system requires careful attention to detail. Generally, the SPD is fitted between each phase (L1, L2, L3), and the PEN conductor. It’s important that the connection to the PEN conductor is made at a point which is guaranteed to be earthed. Because of the neutral-earth merger nature, certain SPD types may be suggested for safe operation under minimal loss conditions and dependable isolation ensuring functionality. The correct wiring is crucial for effective surge protection.

SPD Wiring Considerations for TT Earthing Systems

In earthing system TT, the supply source has a direct earth connection regardless of the consumer’s installation. The consumer installation is equipped with an earth electrode that is independent from the supplier’s earth. This is important for lightning protection.

To wire SPDs in a TT system, the SPD is usually placed between each phase (L1, L2, L3) and the protective earth (PE) to the consumer’s installation. Protecting against surges between neutral and phase is usually done using SPDs placed between phase and earth since neutral is referenced to local earth. The SPD’s efficiency in a TT system is largely dependent on the quality and resistance of the local earth electrode. This configuration must also comply with safety standards.

Conclusion

It’s important to know the earthing system of your installation greatly before interconnecting any SPDs. Failure to comply with correct connections may result in suboptimal surge protection or take the requisite safety standards steps. Consult with an approved electrical worker for the correct wiring diagram applicable to your system and the specific wiring methods.

Key Considerations for Optimal Performance and Longevity of Your 3 Phase SPD

*If you want to find more SPDs, you can click on: https://www.lspele.com/surge-protective-device/

Aside from the proper initial wiring, there are other factors that influence the lifespan and functionality of your three-phase SPD:

- SPD Selection:Choosing an SPD for a specific use case may SPD selection also include consideration of the operating environment of the electrical system. Each SPD has specific markings such as maximum continuous operating voltage (Uc), the protection level measured voltage (Up), and the surge current value among others. If the ratings are chosen below the adequate values, surge events will always be a challenge for the protector.

- Proper Rated SPDs and Wiring Length: Proper rated SPDs may incur severe increase in cost, however, connection leads should always be at the lowest possible length. This results in a lower amount of excess charge that impedes quick response time to SPDs and reduces performance. A better analogy is that the connection should be a straight direct path to where the surge energy will be discharged, much like the function of a lightning protection system directing a strike safely to ground.

- Signage and Circuit Protection:Install signboards on the SPDs stating dedicated overvoltageprotection device for that purpose. If there are other circuit breakers or fuses not specifically recommended, stop using them. The fuse or break serves multiple roles, from protecting the SPD from continuing current to the entire installation acting as an SPD shield, the benefits follow the SPD shield. The main breaker also contributes to this overall protection.

- Routine Check and Cleaning: Regularly check the SPD to see if there is any damage or wear. A lot of SPDs have signs that show their status. If the indicator suggests a fault or if the SPD appears to go through a significant surge event, it should be replaced without delay. This is part of maintaining safety standards.

- Operating Condition: Mount the SPD in an area with temperature and humidity levels that are within the specified tolerances of the SPD*. Performance and longevity of the device may be adversely affected under extreme conditions. The insulation of the SPD should also be inspected.

In ensuring these three-phase SPDs are reliable and durable protectors for highly valuable electrical assets, paying attention to these considerations is crucial for optimal surge protection. Many safety standards, such as IEC and UL , provide guidelines for these considerations.

LSP: Ensuring Reliable 3 Phase Surge Protection with Expertly Designed SPDs

LSP has been specializing in the research, development, and production of Surge Protective Devices (SPDs) since 2010. With the focus on innovation and continual improvements, we achieve remarkable production capacities, exporting to more than 10 countries globally and employing state of the art facilities with 2 fully automated production lines in a factory covering an area of 1,600 square meters. Backed by certifications ISO9001, TUV, CB, and CE, we uphold a commitment to quality that guarantees the products surpass the highest standards. In addition, we provide customized solutions tailored to help clients swiftly secure industry-leading certifications.

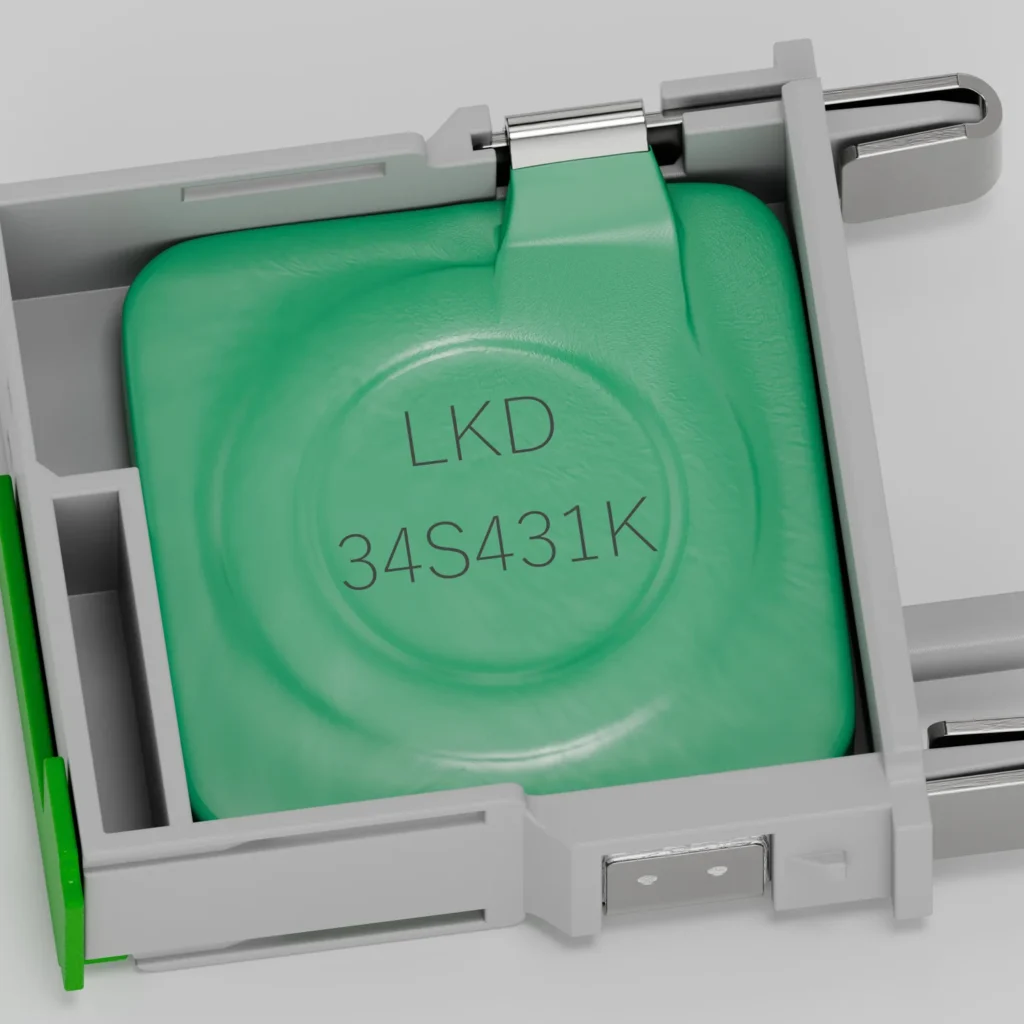

Our SPDs are crafted with the best materials to ensure top-notch performance and longevity. We use high-quality MOVs from the LKD brand, recognized among the top 10 SPD manufacturers globally. Additionally, our GDT components come from Vactech, trusted by major players like Phoenix Contact. Our plastic parts feature enhanced flame-retardant materials (PA6+GF30%), ensuring durability and safety. For metal components, we employ thicker coatings and use advanced metal pins that increase the product’s resilience. With rigorous testing, including salt spray and fire resistance tests, LSP SPDs provide reliable surge protection, even under extreme conditions.

The design and production of LSP SPDs emphasize reliability, efficiency, and protection. Our surge protection devices are designed with advanced features like internal tripping mechanisms, moisture-resistant MOV enclosures, and superior lightning protection capabilities. Our Type 1+2 SPDs are dual-certified, providing enhanced protection for sensitive equipment. We also offer modular designs that meet diverse market requirements, including the 3+1 and 4+0 modes, catering to both European and Chinese standards. Our highly skilled team ensures that each device undergoes meticulous testing, including lightning current impact and temperature stability tests, guaranteeing long-lasting performance in any environment.

Troubleshooting Common Issues and FAQs Regarding 3 Phase SPD Wiring

Even with holding meticulous installation practices, some common issues can arise with the wiring of three-stage SPDs. Here are some problem diagnosis and most common troubleshooting tips:

Receiving questions and giving responses:

- Q: Why is the SPD indicator light off or does not light up?

A: In this case, for the most part first try checking whether the supply voltage to the SPD is on. Check also the upstream circuit breakers or fuses and if they have indeed tripped. If there is power, the SPD can also turn off and would need to be replaced. In case of doubt it is best to read the manual for instructions of the manufacturer.

- Q: The circuit breaker upstream of the SPD keeps tripping.

A: This symptom could mean the SPD unit in question could have some problems such as an internal short circuit issue. The problem may also be an over aggressive circuit breaker, and hence the rating is too low. It is best that specifically starts with checking that the rating of the circuit breaker is indeed from the manufacturers limitutons for the SPD header. In such an event, it is likely also for the SPD that’s integrated is likely in most cases the one designed to be destroyed.

- Q: Is it possible for me to link the SPD to the core busbars with no circuit breaker in between?

A: No, it is generally not advisable and often movements contravening the code are done. A relevant overcurrent protective dissociation device circuit breaker is needed The added functionality expressed in the SPD primary side input port of the circuit is that it affords said circuit protection fromable currents, and improves significantly overall installation safety. The main breaker serves a different purpose in the overall system.

- Q: How often should I replace my SPD?

A: The life expectancy of an SPD‘s components can differ based on how often and how severely the SPD is subjected to surge events. Some manufacturers warn that a complete SPD replacement is necessary after some years, regardless of fault indicators. The indicator lights are crucial for determining the operational status of the device. If a considerable surge has occurred, the device should be discarded. This is a key aspect of maintaining surge protection.

Before tackling complex three-phase systems, ensure you grasp the fundamentals of any standard AC SPD. Whenever there are uncertainties regarding the wiring of the three-phase SPD, make sure to contact a certified and registered electrician who understands safety standards. It is unsafe to attempt any troubleshooting or repairs to electrical equipment without the necessary technical skills or background. Remember to check the wiring diagram for your specific SPD model.

Conclusion: Empowering Your Business with Safe and Secure Three-Phase Power through Correct SPD Wiring

In conclusion, the correct wiring of your three-phase Surge Protection Device is not merely a technical detail; it is a fundamental pillar of your business’s resilience against the damaging effects of power surges. By understanding the importance of each connection, the role of accompanying protective devices, and the nuances of different earthing system configurations, you can ensure that your valuable electrical equipment and critical operations are effectively shielded from transient overvoltages. This includes protection against lightning strikes.

Investing in high-quality SPDs, such as those offered by us, and ensuring their precise installation by qualified professionals is a proactive step towards safeguarding your business continuity, minimizing potential financial losses, and empowering your enterprise with safe and secure three-phase power. Don’t let the unseen threat of power surges compromise your success – make correct SPD wiring.