Introduction: Why True Lightning Safety is More Than Meets the Eye

Most people think of a lightning strike as a simple, direct hit. If your building isn’t the one physically damaged or on fire, it’s easy to assume the danger has passed. But that’s a dangerous misconception. A lightning strike a quarter-mile away can send destructive energy surging into your facility through utility lines, destroying your business operations, wiping out critical data, and frying thousands of dollars in sensitive electronics in a split second.

The truth is, effective lightning protection is a systematic, engineered process. It’s not just about putting a metal rod on a roof. A true Lightning Protection System (LPS) is designed to manage a massive burst of electrical energy, guiding it safely to the ground while simultaneously shielding the delicate electronics that form the backbone of modern life. This requires us to look past the obvious threat of a direct hit and understand the invisible danger of the electrical surge that comes with it. This isn’t about fear; it’s about respecting the power of nature and using intelligent engineering to protect what matters.

What is a Lightning Protection System (LPS)? A 360-Degree View

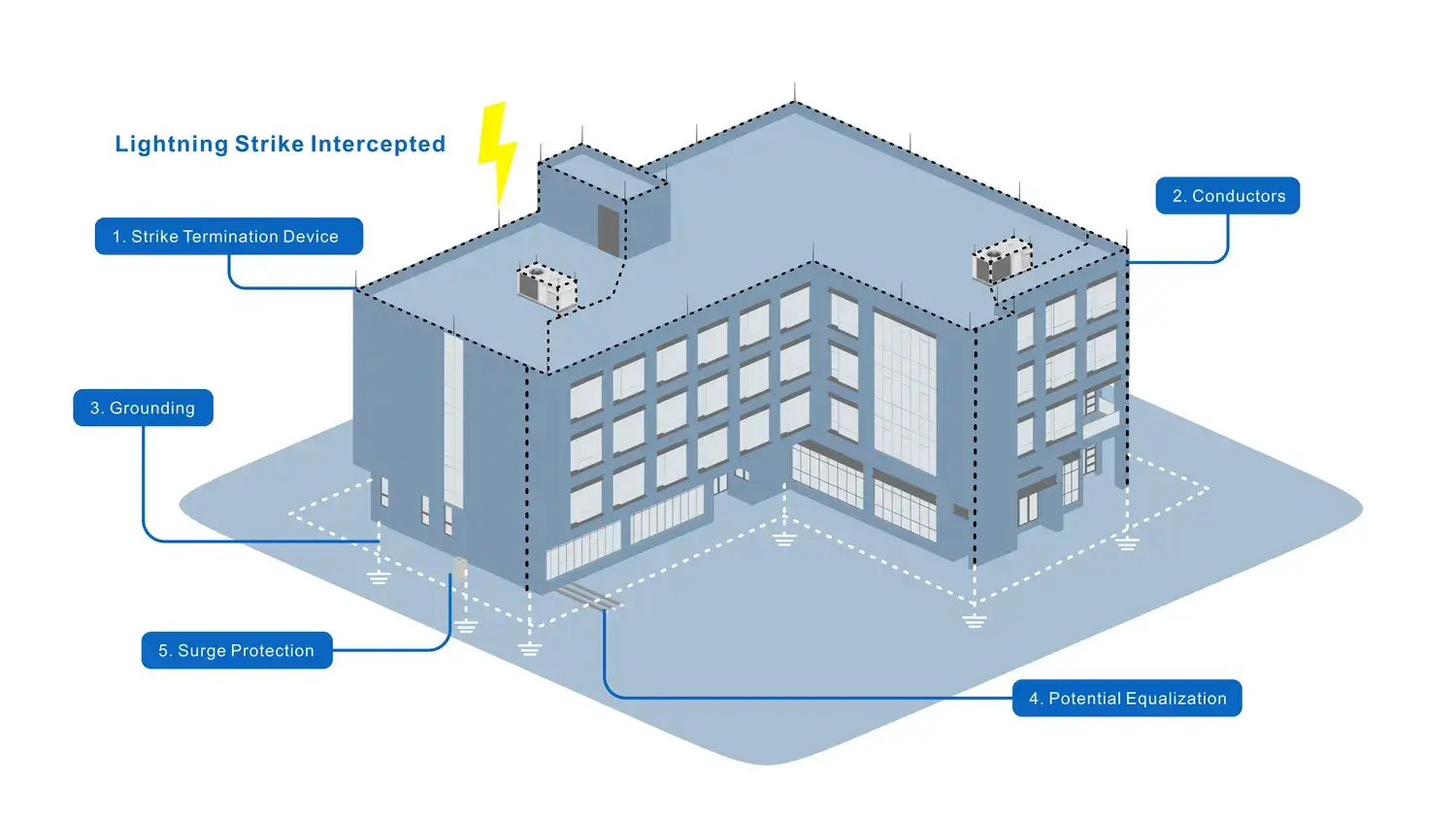

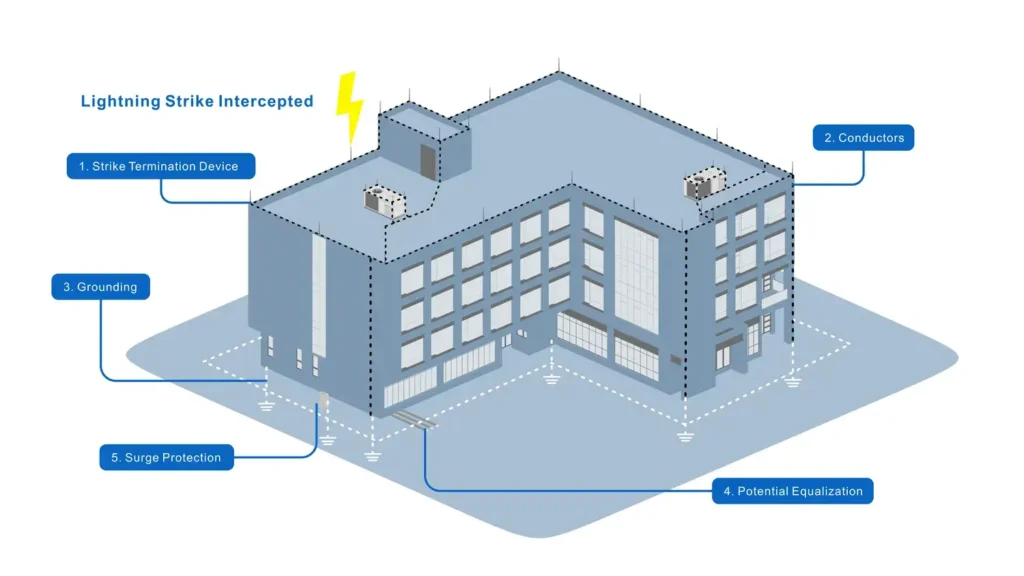

A Lightning Protection System (LPS)is far more than just the lightning rods you see on a roof. It is a complete, passive engineering solution designed to intercept a lightning strike, control its path, and safely dissipate its energy into the earth. Its purpose isn’t to prevent a strike. No technology can do that—but to provide a pre-determined, low-resistance path to the ground. This prevents the immense energy from lightning from tearing through your building’s structure, electrical wiring, or plumbing on its own destructive journey.

In essence, a properly designed LPS gives lightning an easy-to-follow “expressway” to the ground. This safeguards a facility in two critical ways: it protects the building itself from physical damage and fire, and it protects the people and property inside from the devastating effects of the electrical current. It’s an integrated system, and when you have a lightning protection system installed correctly, it transforms a vulnerable structure into a controlled and protected environment.

The Anatomy of a Modern LPS: Its Critical Components

A modern LPS is a system of interconnected external and internal components, each playing a vital role in the chain of protection. For the system to be effective, every part must work in perfect harmony.

External Protection: The First Line of Defense (Rods, Cables, & Grounding)

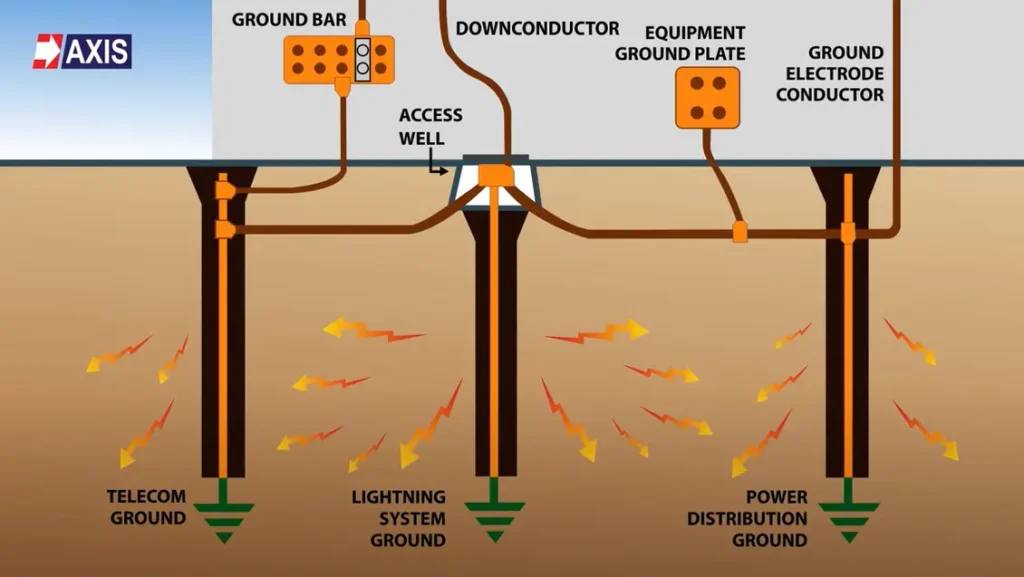

*Schematic Diagram of External Protection

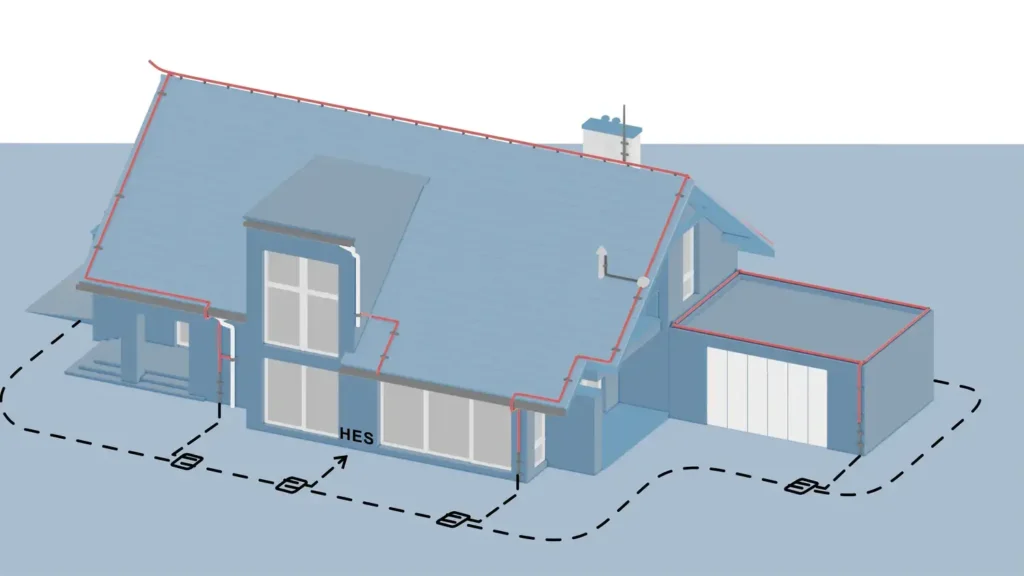

This is the most visible part of the LPS, consisting of three primary components working together:

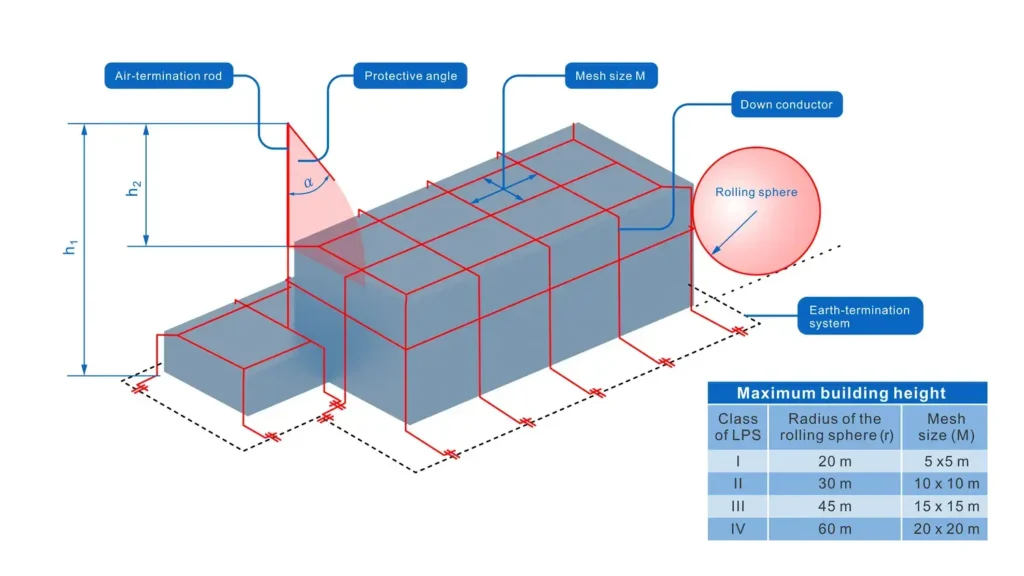

- Air Terminals (Strike Termination Devices): These are familiar lightning rods, made of highly conductive copper or aluminum. Placed at strategic points on a structure—like roof peaks, chimneys, and corners—the job of these terminals is to intercept a lightning strike before it hits the building. They don’t attract lightning, but rather provide a safe and intended point of contact for a strike that is already forming.

- Conductor Cables: These heavy-duty cables are the main pathways for the electrical charge. These conductors run across the roof and down the sides of the building, connecting all air terminals into a single conductive grid. Their purpose is to provide a low-impedance route to carry the immense current from the air terminals down to the ground. Their layout is crucial; they must be as straight as possible, avoiding sharp bends that could cause the current to arc (or “flash over”) to other parts of the building.

- GroundingSystem (Ground Electrodes): This is the final and most critical destination for the lightning current. The conductor cables connect to a series of ground rods driven deep into the earth (typically at least 10 feet). The sole purpose of this grounding system is to safely disperse the lightning’s energy into the ground. A low-resistance connection to the earth is essential to prevent energy from backing up and causing harm.

Internal Protection: The Unseen Shield for Your Valuables

While the external system handles direct strikes, the internal system deals with the secondary effects. A powerful lightning current creates a massive electromagnetic field and can induce dangerous surges on any connected wiring. To counter this, there are two primary internal protection strategies:

- Equipotential Bonding: This involves connecting the LPSconductors to a building’s other metallic systems (water pipes, gas lines, and structural steel) using bonding connectors. Bonding ensures that all metallic systems are at the same electrical potential during a strike, which prevents dangerous side-flashes where lightning jumps between objects.

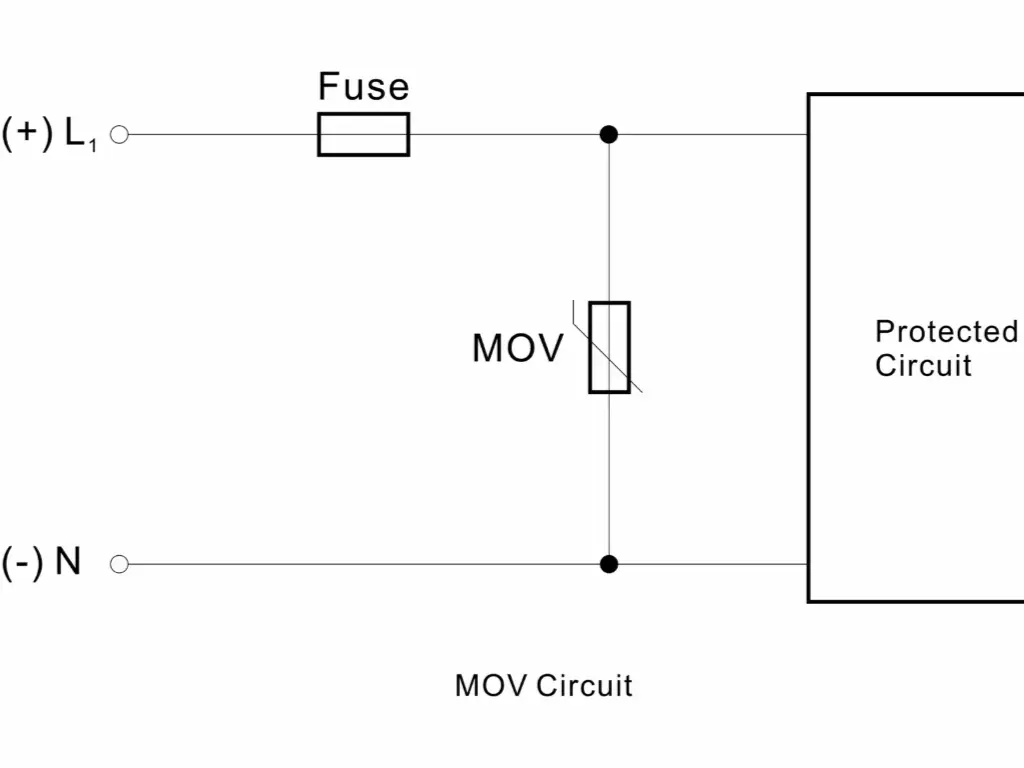

- Surge Protection: This is arguably the most crucial internal defense for modern buildings. While bonding prevents side-flashes, Surge Protective Devices (SPDs) are needed to stop surges from entering through utility lines (power, data, phone) and destroying sensitive electronics.

The Hidden Danger: Why Your LPS is Incomplete Without the Right Surge Protection

You’ve installed a robust external LPS. Your building is protected from fire, and equipotential bonding prevents side-flashes. You’re safe, right? Not completely. The very same lightning strike safely guided to ground by your LPS has created a secondary threat that is now traveling towards your building on its power and data lines. This is the most common and costly oversight in lightning protection.

Secondary Effects of a Lightning Strike: The Threat to Your Electronics

A lightning strike—even one that hits a power line a mile away—can induce a powerful and incredibly fast electrical surge, known as a transient voltage. This surge travels along wiring at nearly the speed of light, entering your building and seeking a path to ground. All too often, the microprocessors in your computers, servers, security systems, and industrial controls provide that path.

The result is instant destruction. A surge lasting mere microseconds can obliterate components designed for precise, low voltages. It can permanently damage circuit boards, rendering your most valuable equipment useless. This means that even witha perfect external LPS, you can still suffer catastrophic financial and data losses from surges entering through your utility connections.

Global Standards for a Global Threat: Understanding US Compliance vs. Global Performance

When protecting a facility, especially in the United States, it’s crucial to understand the two different philosophies behind surge protection: baseline code compliance and mission-critical performance.

The Foundation: Code Compliance in the U.S.

For a lightning protection system to be formally certified under standards like UL 96A, the rules are very clear. The National Electrical Code (NEC) and the local Authority Having Jurisdiction (AHJ) require that components installed at the electrical service entrance be “Listed” by a Nationally Recognized Testing Laboratory (NRTL), such as UL. This means the primary, Type 1 SPD protecting the whole building generally needs to be UL 1449 Listed to pass inspection. This is the baseline for ensuring a building’s electrical system is safe and compliant.

Beyond Compliance: Protecting Your Most Valuable Assets

- Standards Ready: IEC/EN 61643-11, TUV, CB, CE certified

- End-to-End Defense: Covering all levels — Type 1, Type 2, Type 1+2, and Type 3 for critical equipment

- Safe by Design: Independent disconnector and flame-retardant casing

- No Delays, No Minimums: Flexible orders, zero MOQ, fast customization

For facilities with zero tolerance for downtime—such as data centers, advanced manufacturing plants, or broadcasting studios—merely meeting the baseline standards is insufficient. The financial impact of even a few minutes of downtime can far exceed the cost of the equipment itself, making it critical to have surge protection that goes beyond compliance.

At LSP, we focus on providing surge protective devices (SPDs) that not only meet but exceed the rigorous IEC 61643-11 standards. Our SPDs are engineered for the most extreme surge events, such as lightning strikes or switching operations. With MOVs sourced from the trusted LKD brand and GDTs from Vactech, we ensure that our devices can withstand up to 20kA of surge current, keeping your equipment safe under even the most challenging conditions. This level of protection is essential for minimizing risk and maximizing uptime in mission-critical environments.

Our approach offers a performance-driven strategy that supplements the baseline compliance requirements with an industrial-strength layer of protection exactly where it is needed most. By utilizing advanced features like our internal disconnect mechanism—designed to isolate and extinguish arcs and prevent fires—along with our modular, customizable designs, we ensure that every installation provides not only compliance but also superior performance. At LSP, we deliver peace of mind, knowing your assets are protected against the most severe surges and their devastating consequences.

The Installation Process: From Assessment to Certification

A professional LPS installation is a specialized trade governed by strict national standards. The process is methodical:

| Step | Description |

| 1. Risk Assessment | A certified professional evaluates the structure’s location, size, construction, and contents to determine if an LPS is needed and what level of protection is required, typically following the NFPA 780 standard. |

| 2. System Design | Using architectural drawings and a site survey, the specialist designs a custom system, mapping out the placement of air terminals, conductor paths, grounding electrodes, and specifying the appropriate surge protection strategy. |

| 3. Installation | Certified technicians install the system using approved components. This requires expertise in proper bonding techniques, conductor routing, and achieving a low-resistance ground connection. |

| 4. Inspection and Certification | After installation, the system can be inspected by a third-party organization like UL. If it meets all requirements of a standard like UL 96A, a Master Label Certificate may be issued, verifying a compliant design and installation. |

Choosing Your Installer: 6 Questions to Ask Before You Hire

The success of your protection plan is based on the experience of your installer. These are some of the key questions to ask a contractor before they are hired to ensure that they know both compliance and performance:

- Do your installers have Lightning Protection Institute (LPI) certification to install systems in compliance with NFPA 780?

- Do you ensure that the main service-entrance surge protector you install will be UL-listed to comply with NEC and local code requirements?

- In addition to simple code compliance, how do you plan to offer additional surge protection to our most important and valuable electronic equipment, such as our servers or process controllers?

- Do you know how to design layered protection schemes (e.g. with Type 1, Type 2 and Type 3 devices) to protect critical loads downstream of the main panel?

- To protect our most important assets, have you been involved in specifying high-performance SPDs on the basis of their capability to withstand extreme surges, including those characterized by the IEC 10/350 µs test waveform?

- Is there a detailed proposal that you can give us that describes the primary code-compliant system and any suggested additional protection measures to our critical equipment?

Conclusion: Build a System That’s Truly Storm-Ready

An approaching storm is the last test of preparation. Hope is not a plan, but smart engineering is. The modern world demands a two-pronged approach to complete lightning protection: a strong, code-compliant lightning protection system as the initial line of defense, and a high-performance, specialized surge protection strategy of the critical electronics that drive your operations. Whereas baseline compliance secures the building, performance secures your business continuity.

It is an investment in strength, continuity, and tranquility. When the storm hits, you will not be crossing your fingers and hoping that things will turn out alright; you will be relying on a fully functioning, smart system that is meant to safeguard what is most important.

When your facility has already satisfied its minimum code requirements and you simply cannot afford the risk of losing your most valuable assets to downtime, it is time to discuss a supplemental protection strategy. Call our specialists to find out how our high-performance, IEC-tested SPDs can offer mission-critical protection your equipment needs.