Whether in a residential house or a large industrial plant, electrical power management is a basic necessity in any modern structure in terms of functionality and safety. The distribution board is the heart of this whole process. Although it might seem like a mere metal or plastic box, it is the control center of the electrical system of the building. Knowing its operation, parts, and limitations is not just an academic exercise but a precondition for anyone who is engaged in the design, installation, or maintenance of electrical installations. This guide offers a comprehensive, professional analysis of the distribution board, starting with the basic principles and going to the high-level protective measures needed in contemporary technologically saturated settings.

The Basics: What Exactly is a Distribution Board?

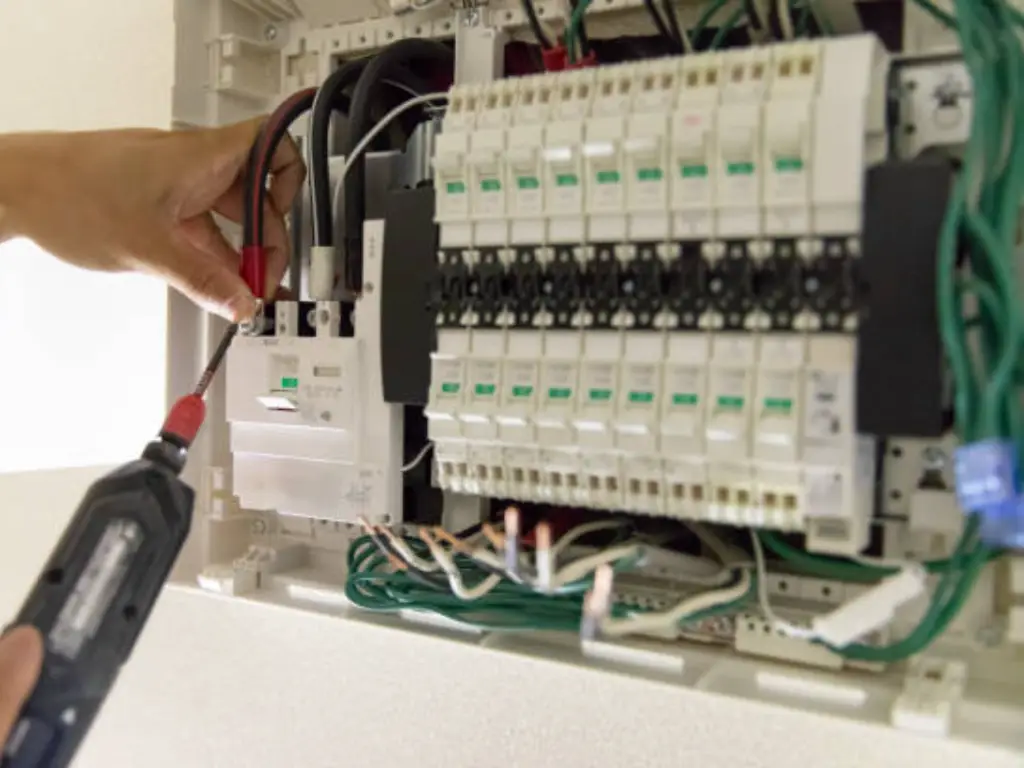

A distribution board (also called a breaker panel, panelboard, or consumer unit in domestic installations) is the point at which the main electrical power feed is controlled and distributed to secondary circuits within a building. It is strategically placed, usually where the primary incoming power supply cable enters the premises after the utility meter. The fundamental role of any distribution board is two-fold, including distribution and protection.

The first is that it is mainly charged with the responsibility of taking the bulk electrical power that is supplied and splitting it into smaller and manageable units. These are then fed into other circuits that supply power to other areas or types of loads in the building, such as lighting in one area, power outlets in another, and dedicated circuits to high-demand electrical loads such as HVAC systems. Such a division guarantees a rational and structured network of power distribution.

Second, and probably its most important role, is circuit protection. Every circuit starting on the distribution board has a protective device assigned to it, usually a circuit breaker. This device continuously checks the flow of electricity and is designed to automatically disconnect the electrical supply in case it senses a fault, e.g., overcurrent or short circuit. This is an immediate response that avoids damage to equipment, reduces fire risks, and is a pillar of contemporary electrical safety.

A Look Inside: Key Components of a Distribution Board

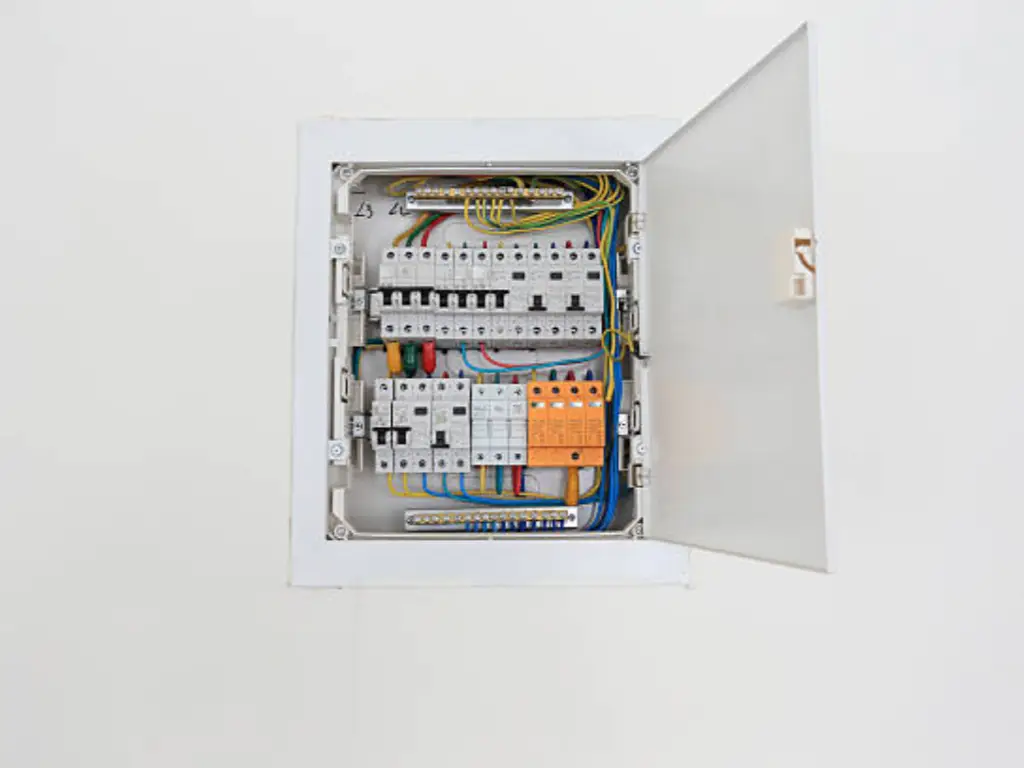

The quality and appropriate arrangement of the internal components of a distribution board establish its reliability and effectiveness. Although designs may differ depending on the application and regional electrical codes, there are a number of central components that are always present. These parts require a thorough knowledge to be properly specified and maintained.

The Main Switch: Your Master Power Control

The first major component that the incoming power will come across on the board is the main switch or the main breaker. It acts as a master control, and the entire electrical system can be disconnected completely from the grid. This is essential during maintenance, emergencies, or when significant alterations are being made to electrical installations. The main switch in most setups also offers a first level of overcurrent protection to the whole panel, and is rated to carry the total maximum building load.

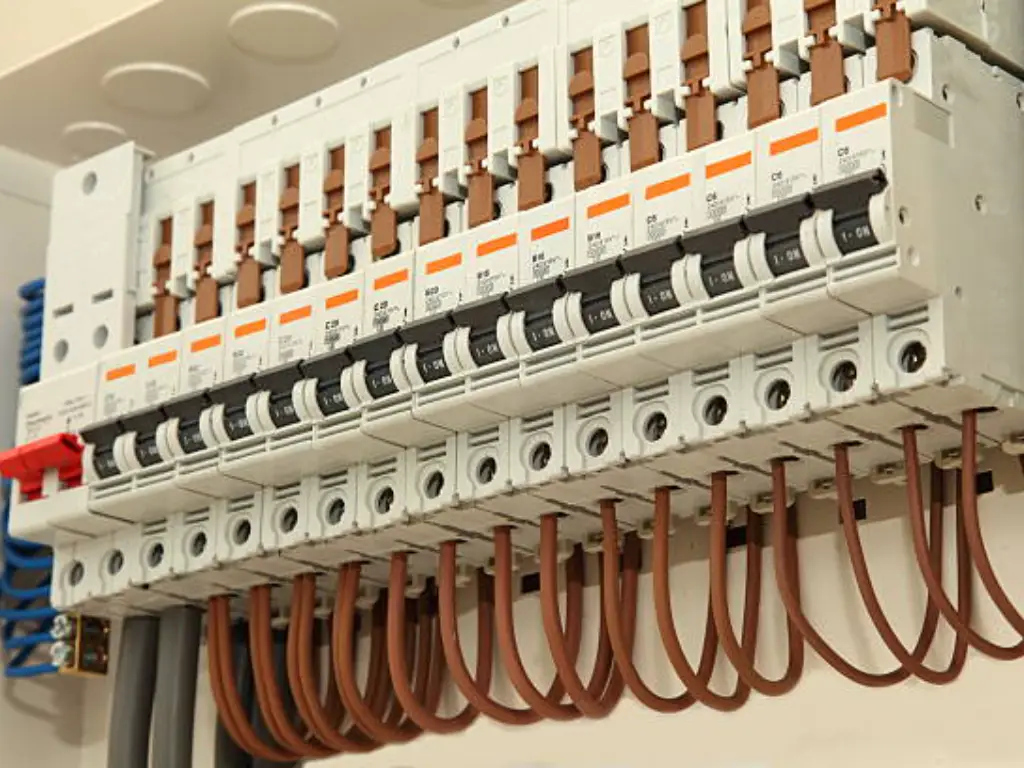

Circuit Breakers (MCBs & RCBOs): The Guardians of the Circuit

Beyond the main switch, the electrical power is routed to the overcurrent devices of the individual circuits.

Modern distribution panels have mostly replaced older fuse systems with Miniature Circuit Breakers (MCBs). An MCB is an automatic electromechanical switch that is used to protect a particular circuit against damage by overcurrent. It does this by breaking the electricity supply, or tripping, when it senses either an overload (a current slightly above the rating of the circuit maintained over some time) or a short circuit (a very high current surge). Once a fault has been cleared, the MCB may be manually reset, a major advantage over single-use fuses.

The Residual Current Devices (RCDs) and Residual Current Breakers with Overcurrent Protection (RCBOs) offer an increased level of safety aimed at the protection of people against electric shock. An RCD, also known as a Ground Fault Circuit Interrupter (GFCI), operates by continuously checking the current in the live and neutral wires of a circuit. Should it sense an imbalance, which would mean that the current is flowing to the ground, perhaps through the body of a person, it trips nearly instantly. An RCBO has the overcurrent protection of an MCB and the earth fault protection of an RCD in a single, compact device mounted on the DIN rail, offering the greatest combined personnel and equipment protection of a given circuit.

Busbars and Terminals: The Electrical Highway

The Busbar is a very important element of effective power distribution within the panel. It is normally a metallic strip, usually copper or aluminum, to which the miniature circuit breakers are attached. The busbar is connected to the main switch and carries the entire current to all the breakers, which are connected to it as a common point. This design is easy to wire, minimizes clutter, and provides a dependable low-resistance path to electrical energy.

All incoming and outgoing wiring is securely connected at terminals. Neutral and earth terminals are offered in separate blocks, so all the circuits are terminated correctly to operate safely and compliantly. The soundness of these connections is crucial to the general safety of the electrical system.

With the increasing complexity of systems, another device is becoming more common within the modern boards: the Surge Protective Device (SPD). It is a sophisticated safety element that is used to guard against another type of electrical hazard, which will be explained in more detail below.

How Does a Distribution Board Work?

Power transmission via a distribution board is a logical process that has a clear flow, and this makes sure that electric power is conveyed safely and effectively to the required location.

- Incoming Supply: The process starts at the power grid of the utility. The electrical power supply enters the property through the electric meter of the property, which measures consumption.

- Main Cable: The main or feeder cable is a heavy-gauge cable that conveys the entire electrical load between the meter and the main distribution board.

- Connection to the Board: The primary cable is connected to the line-side of the main switch or main breaker.

- Distribution through Busbar: In this case, when the main switch is in the on position, the power is transferred through it to the main busbar. The busbar energizes the line side of all the circuit breakers connected to it.

- Circuit Division: A circuit breaker (MCB or RCBO) is connected between the busbar and a smaller cable that supplies a particular final distribution board or one of the many circuits, e.g., the lighting on the ground floor or the power sockets in the kitchen.

- Final Load: The power is then passed through these subsidiary circuits to the end of the line of use, a light, a computer, or an industrial machine. Each circuit’s neutral and earth wire is connected back to the terminal bar of the same circuit on the distribution board, completing the electrical loop.

All this is constantly checked by the protective devices. In the event of a fault on any of the various circuits, only the breaker on that circuit will trip, and the remaining circuits in the electrical system remain available.

Common Types of Distribution Boards You’ll Encounter

Distribution boards are not one-size-fits-all. They are designed and specified based on the electrical requirements and environmental factors of their intended setting. The primary distinctions are based on application and structural hierarchy.

Classification by Application

- Residential (Single-Phase): In the majority of residential and small commercial applications, the power is single-phase. The equivalent distribution board, sometimes referred to as a consumer unit or fuse box, is smaller and capable of lower electrical loads. It will generally have a main switch, one or two RCDs protecting banks of MCBs, or a complete set of RCBOs to provide separation of circuits.

- Commercial & Industrial (Three-Phase): Bigger buildings need a three-phase electric service to run heavy equipment and large systems. These distribution panels are much larger and more complicated. They operate a three-phase supply and feed power to a far greater number of circuits, commonly with special breakers such as Molded Case Circuit Breakers (MCCBs) with higher current ratings. They are typical of industrial areas, factories, and big office buildings.

Classification by Structure

In large electrical installations, a hierarchical approach to power distribution is used.

A hierarchical power distribution is employed in large electrical installations.

- Main Distribution Boards (MDBs): The MDB is the first and main board after the main utility feed. It takes the total supply and breaks it down into large sub-circuits that supply smaller, secondary panels.

- Sub-Distribution Boards (SDBs): SDBs are also referred to as final distribution boards, and they are fed by the MDB. They are placed nearer to the end loads in certain areas or parts of a building, say on various floors or in special workshops. They also separate the power into the last circuits of lighting, power, and appliances.

Specialized Applications

The field of power distribution is evolving. Specialized distribution boards are now common for applications like Photovoltaic (PV) solar systems and Energy Storage Systems (ESS), which often require management of Direct Current (DC) power. Communication hubs and 5G base stations also utilize specialized DC or hybrid AC/DC distribution panels tailored to the specific needs of sensitive telecommunications equipment.

The Built-in Safety Limit: Overcurrent vs. Overvoltage

One of the most important distinctions of any electrical professional is the one between overcurrent and overvoltage. Although both are electrical faults, they are of different origins and need different protective solutions.

As the name suggests, overcurrent is a condition in which the current flowing in a circuit is more than the rated current. It is an internal issue that either occurs due to an overload (connecting too many high-power devices to a single circuit) or a short circuit (a fault that provides a low-resistance path). Miniature Circuit Breakers (MCBs) are specifically made to sense such conditions and are very efficient in offering overcurrent protection.

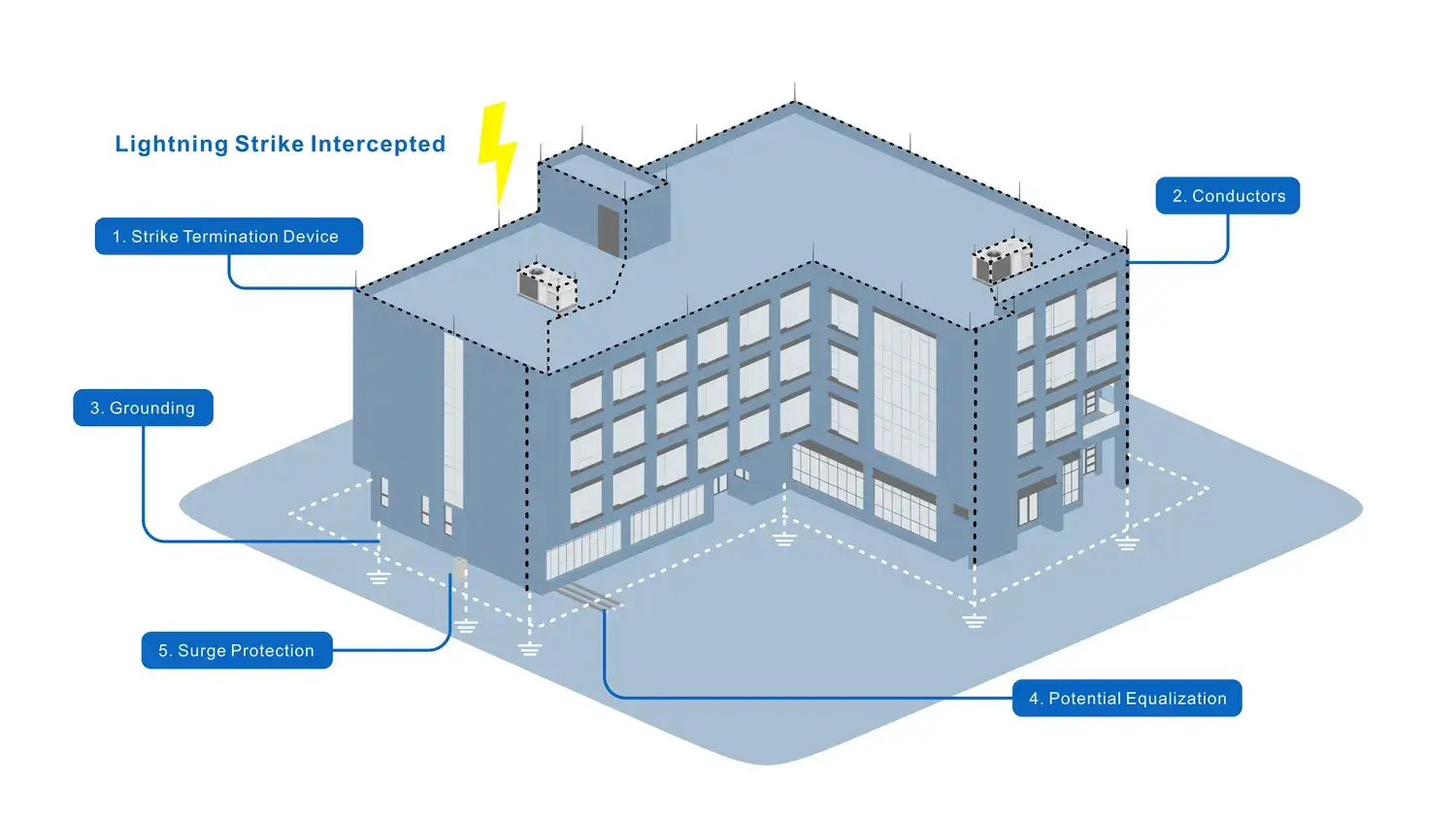

A different threat, however, is overvoltage. It is an abrupt rise in the voltage of the circuit, which takes it way beyond the normal operating voltages. The main sources of these voltage transients, or surges, are external events such as lightning nearby or grid switching operations by the power utility on a large scale. The typical circuit breaker does not see these events. It is not a voltage (Volts) meter but a current (Amps) meter. A typical distribution board, therefore, provides virtually no protection against external voltage attacks, This reality makes knowledge of essential distribution board components vital for designing reliable surge protection. And sensitive modern electronics can be instantly and permanently damaged.

Completing the Shield: The Role of Surge Protection (SPDs)

- Fire protection design, 5-year warranty

- Top tier raw materials: MOV from LKD®, GDT from Vactech®, etc.

- 300,000 pcs/year

This is where the Surge Protective Device (SPD) is a must-have element of a contemporary electrical safety system. The SPD is specifically designed to fill the safety gap that is left by conventional breakers. It is intended to sense and safely reroute transient overvoltages off your equipment.

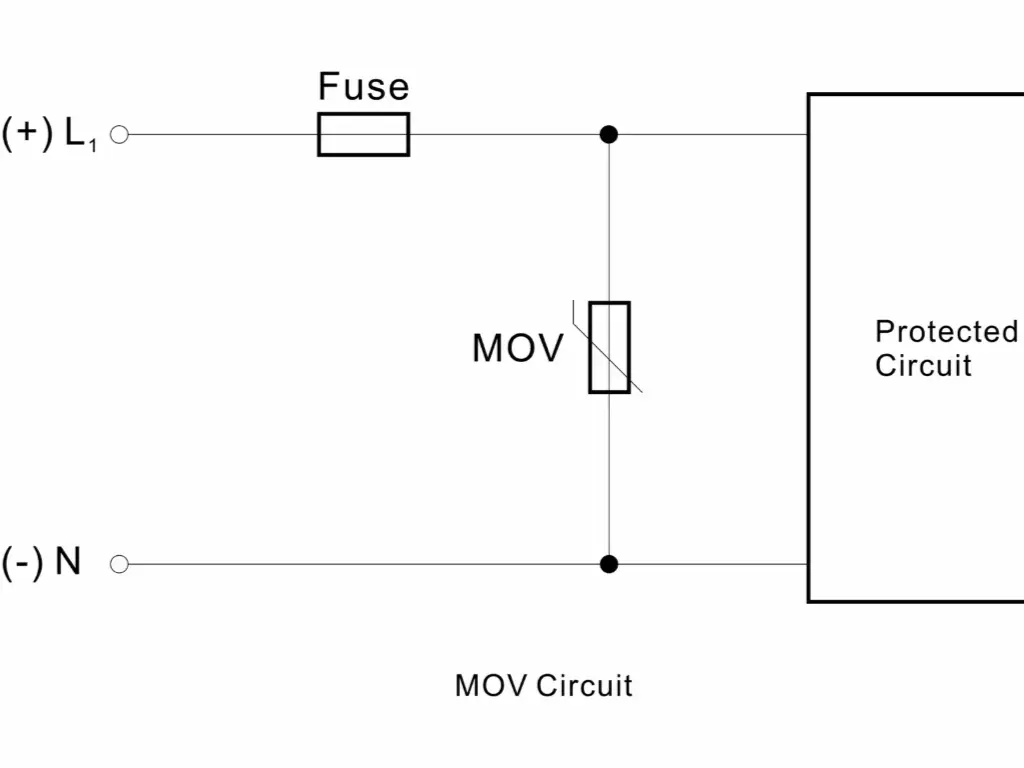

An SPD is a parallel device. At normal voltages, it is in high-impedance mode and does nothing. But, as soon as it senses a voltage spike that is too high, its impedance immediately falls to zero, providing a safe path to the excess electrical energy to be diverted to the earth/ground system. This measures short-circuits the voltage to a safe level and safeguards all downstream equipment. The whole process occurs in nanoseconds, well before the voltage can damage.

Effective surge protection cannot be simply a matter of adding any device. The most important thing is the quality, durability, and certification of the SPD. Being a manufacturer of SPDs since 2010, LSP has been concerned with the development of devices that could satisfy the strict requirements of professional industrial use and high-end residential requirements. The essence of any high-performance SPD is its internal components, mainly the Metal Oxide Varistor (MOV) and the Gas Discharge Tube (GDT). We use the finest components, including LKD brand MOVs, used by the major manufacturers of SPDs worldwide, and Vactech GDTs, to provide superior reliability. A professionally specified SPD by a quality manufacturer such as LSP can survive several surge events (e.g., a Type 2 SPD tested to In=20kA for +/-5 impulses) without serious degradation. This is a decisive aspect of panel builders, PV system integrators, and telecom infrastructure companies who cannot afford failures. Moreover, the SPD is designed with advanced capabilities such as a strong, in-house developed thermal disconnection mechanism to ensure that the SPD safely disconnects itself at the end of its life without becoming a fire hazard, a testament to engineering that places high value on comprehensive electrical safety based on strict safety standards such as IEC/EN 61643-11.

Conclusion: A Complete Safety System for Modern Electrical Needs

A distribution board is undoubtedly an important part of the infrastructure of any building. It offers the necessary services of systematic power distribution and basic overcurrent protection. But the needs of the modern world, which is full of microprocessor-based, voltage-sensitive electronics, demand a more comprehensive approach to safety.

An effective safety plan is one that realizes that contemporary electrical risks are not only internal but also external. The full system, then, is one in which a well-designed distribution board with accurate overcurrent protection (MCBs and RCBOs) is complemented by professionally-specified and installed surge protection (SPDs). This combined system offers complete protection, not only against fire of the wiring and property, but also against the destructive effects of overvoltage on valuable electronic equipment.

To electrical professionals, distributors, panel builders, and installers in the PV and telecom industries, it is no longer an option to specify and install a complete protective system, but a responsibility. If you want to know more about choosing the right SPD to suit your particular application or want to talk to us about bespoke solutions to your projects, contact LSP today.